High-carbon high-chromium duplex stainless steel

A duplex stainless steel, high-carbon and high-chromium technology, applied in the field of duplex stainless steel, can solve the problems of less high-carbon duplex stainless steel, increased production difficulty and cost, and does not involve material structure and performance, so as to improve the strength and hardness of the alloy , Reduce production cost and difficulty, the effect of convenient materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

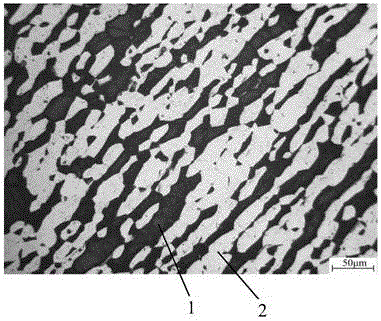

Image

Examples

Embodiment 1

[0025] A high-carbon and high-chromium duplex stainless steel. The chemical composition of the stainless steel is as follows: 0.35%C, 23%Cr, 12%Ni, 3.5%Mo, 4%Cu, 0.5%V, 2.7%W, 0.015%S, 0.010%P, 1% other impurity elements, and the balance is Fe.

[0026] The specific steps of its preparation process are as follows:

[0027] (1) Melting and casting The raw materials are mixed and melted according to the above ratio and then cast into ingots at 1550°C;

[0028] (2) Forging Forge the above ingot at 1200°C into a steel plate;

[0029] (3) Rolling The forged steel plate is rolled into steel plate at 1100°C;

[0030] (4) Solution treatment: Heat the rolled steel plate to 1150°C, keep it warm for 60 minutes, and then quench it to obtain the product. Example 2

Embodiment 2

[0031] A high-carbon and high-chromium duplex stainless steel. The chemical composition of the stainless steel is as follows: 0.20%C, 25%Cr, 10%Ni, 2%Mo, 2%Cu, 3.1%V, 0.5%W, 0.015%S, 0.010%P, 1% other impurity elements, and the balance is Fe.

[0032] The specific steps of its preparation process are as follows:

[0033] (1) Melting and casting The raw materials are mixed and melted according to the above ratio and then cast into ingots at 1570°C;

[0034] (2) Forging Forge the above ingot at 1150°C into a steel plate;

[0035] (3) Rolling The forged steel plate is rolled into steel plate at 1150°C;

[0036] (4) Solution treatment: Heat the rolled steel plate to 1300°C, keep it warm for 20 minutes, and then quench it to obtain the product. Example 3

Embodiment 3

[0037] A high carbon and high chromium duplex stainless steel, the chemical composition of the stainless steel is as follows: 0.25%C, 24%Cr, 14%Ni, 3%Mo, 5%Cu, 2.2%V, 5%W, 0.005% S, 0.015% P, 0.5% other impurity elements, and the balance is Fe.

[0038] The specific steps of its preparation process are as follows:

[0039] (1) Melting and casting The raw materials are mixed and melted according to the above ratio and then cast into ingots at 1600°C;

[0040] (2) Forging Forge the above ingot at 1170°C into a steel plate;

[0041] (3) Rolling The forged steel plate is rolled into steel plate at 1050°C;

[0042] (4) Solution treatment Heat the rolled steel plate to 1200°C, keep it warm for 40 minutes and then quench it to obtain the product. Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com