High-toughness steel plate with yield strength at 460 MPa grade and production method thereof

A technology of yield strength and production method, which is applied in the field of medium and heavy plate manufacturing, can solve problems such as complex manufacturing process, heavy rolling mill load, and cracks on the slab surface, and achieve good toughness and welding performance, good low-temperature impact toughness, ferrite The effect of fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

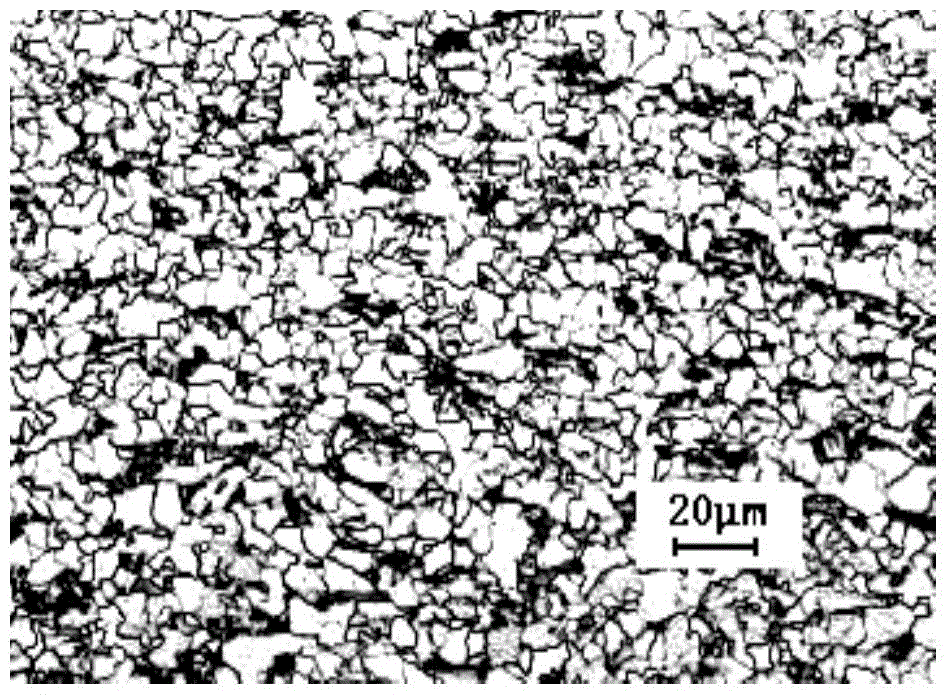

Embodiment 1

[0041] The thickness of the continuous casting slab selected in Example 1 is 253 mm.

[0042] During the heating process of the continuous casting slab, the temperature of the continuous casting slab out of the furnace was 1193° C., and the heating time was 313 minutes. The mass percentage of the chemical composition of the continuous casting slab includes: C0.074%, Si0.24%, Mn1.5%, P0.007%, S≤0.005%, Nb0.052%, V0.058%, Ti0. 012%, Ca0.0027%, Als0.023%, the balance is Fe and unavoidable impurities.

[0043] Then the heated slab is subjected to the first-stage rolling and the second-stage rolling, and a steel plate with a thickness of 30 mm is obtained after the two-stage rolling processes are completed. The steel plate is then cooled.

[0044] Rolling and cooling process have little influence on the content of the chemical composition of the material of steel plate, therefore, the mass percentage of the chemical composition of the material of the steel plate of the embodiment...

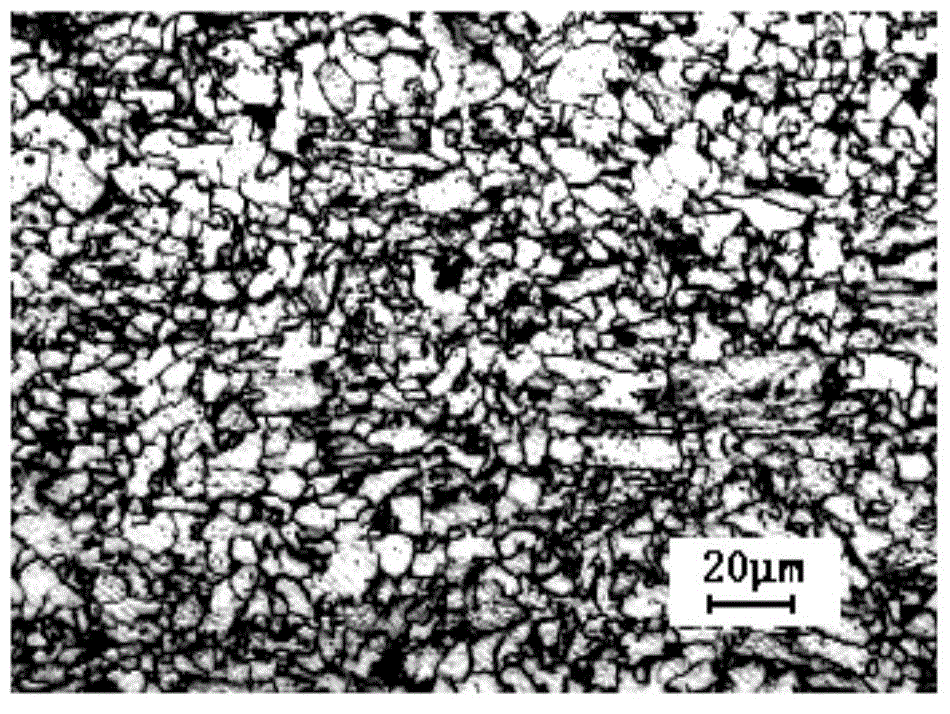

Embodiment 2

[0048] The thickness of the continuous casting slab selected in embodiment 2 is 253 mm.

[0049] During the heating process of the continuous casting slab, the temperature of the continuous casting slab out of the furnace is 1220° C., and the heating time is 326 minutes. The mass percentage of the chemical composition of the continuous casting slab includes: C0.074%, Si0.24%, Mn1.5%, P0.007%, S0.005%, Nb0.052%, V0.058%, Ti0. 012%, Ca0.0027%, Als0.024%, the balance is Fe and unavoidable impurities.

[0050] Then the heated slab is subjected to the first-stage rolling and the second-stage rolling, and a steel plate with a thickness of 30 mm is obtained after the two-stage rolling processes are completed. The steel plate is then cooled.

[0051] Rolling and cooling process have little influence on the content of the chemical composition of the material of steel plate, therefore, the mass percentage of the chemical composition of the material of the steel plate of the embodiment...

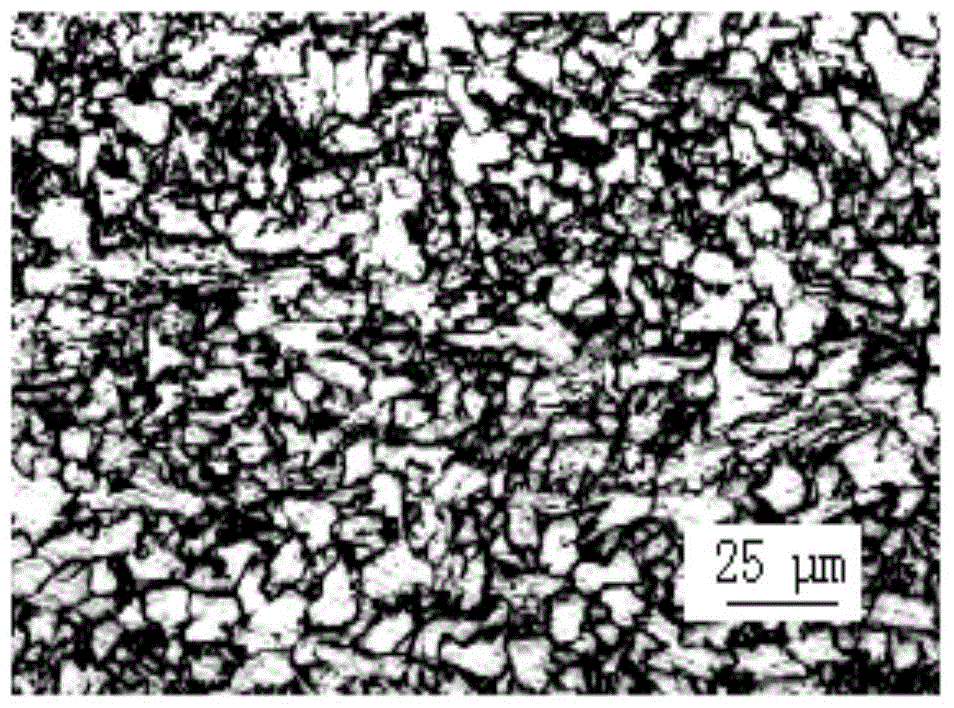

Embodiment 3

[0055] The thickness of the continuous casting slab selected in embodiment 3 is 250mm.

[0056] During the heating process of the continuous casting slab, the temperature of the continuous casting slab out of the furnace is 1180° C., and the heating time is 275 minutes. The mass percentage of the chemical composition of the continuous casting slab includes: C0.05%, Si0.25%, Mn1.6%, P0.011%, S0.01%, Nb0.06%, V0.04%, Ti0. 01%, Ca0.0018%, Als0.017%, the balance is Fe and unavoidable impurities.

[0057] Then the heated slab is subjected to the first-stage rolling and the second-stage rolling, and a steel plate with a thickness of 25 mm is obtained after the two-stage rolling processes are completed. The steel plate is then cooled.

[0058] Rolling and cooling process have little influence on the content of the chemical composition of the material of steel plate, therefore, the mass percentage composition of the chemical composition of the material of the steel plate of the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com