A kind of high heat resistance, high strength cemented carbide and its preparation method

A cemented carbide and high-strength technology, applied in the field of high heat resistance, high-strength cemented carbide materials and their preparation, can solve the problems of unfavorable alloy performance and influence, and achieve avoidance of adverse influence, good distribution uniformity, and active high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the mass percentage is 93.76%WC and 5.87%Co powder and mass percentage is 0.1%CoAl and 0.27%Co 3 W 3 After C powder is wet-milled and mixed evenly, it is spray-dried to make a mixture, and then pressed to make a compact. After liquid-phase sintering at 1500°C, the compact was cooled from the sintering temperature to 700°C at a cooling rate of 10°C / min for 40 hours of heat preservation and aging treatment; finally, it was slowly cooled to room temperature to obtain γ'(Co 3 (Al,W)) phase strengthened Co binder phase of high heat resistance, high strength cemented carbide.

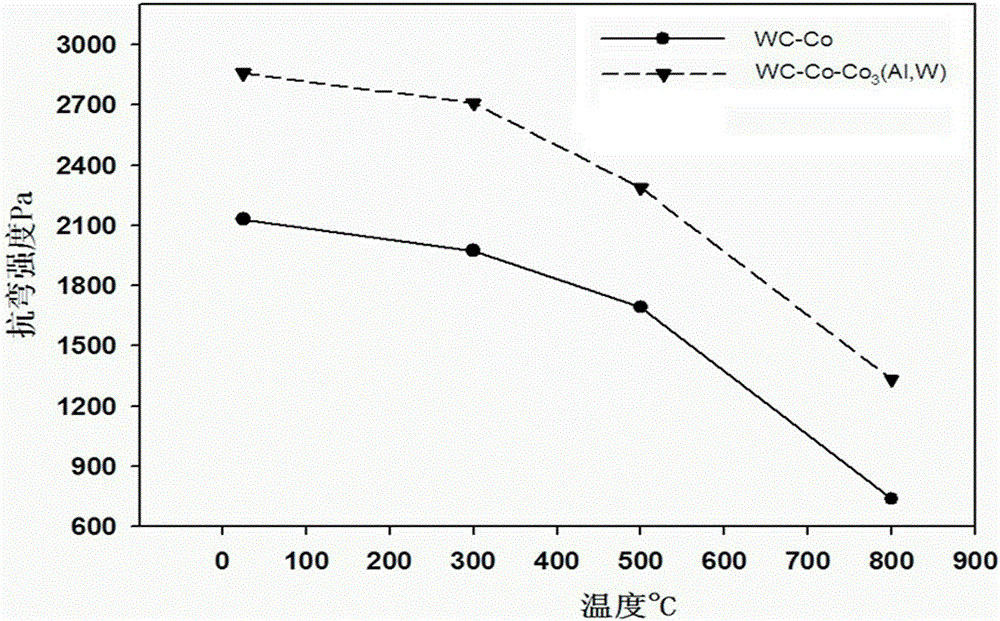

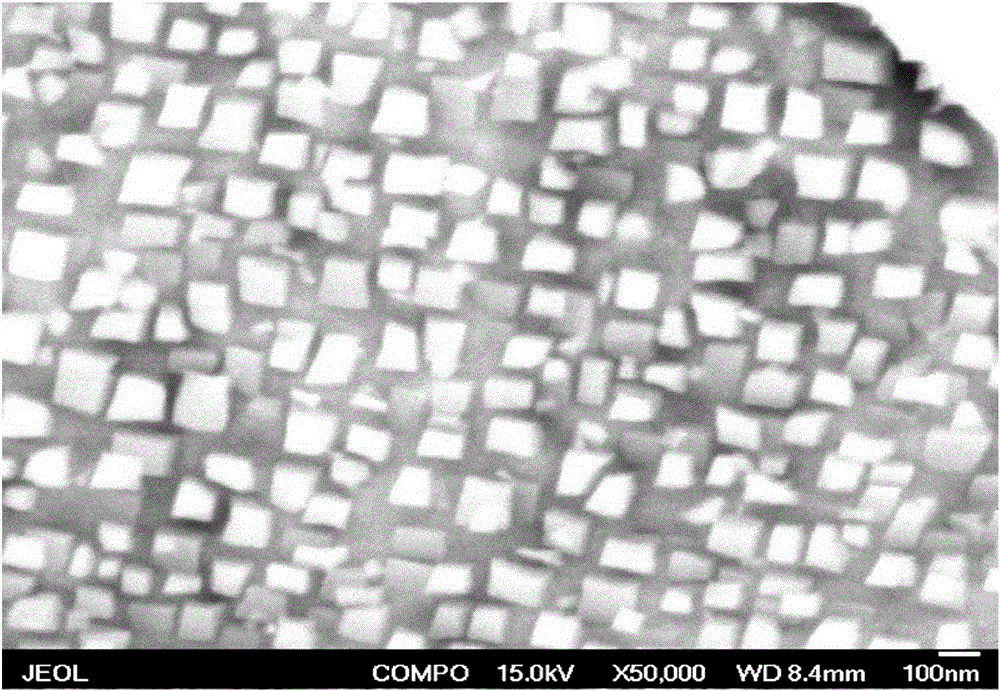

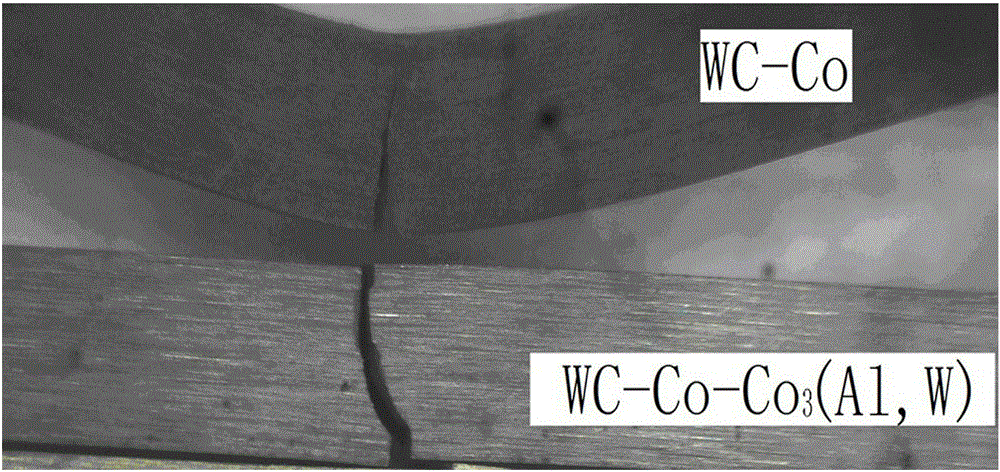

[0026] After corrosion, the typical morphology of the bonding phase is as follows: figure 1 shown. figure 2 It is a comparison diagram of the appearance of the fracture after the three-point bending flexural strength test of the high heat-resistant, high-strength cemented carbide of the present invention and the ordinary WC-Co cemented carbide with the same composition at a temperatur...

Embodiment 2

[0027] Embodiment 2: the mass percentage is 93.52%WC and 5.91%Co powder and mass percentage is 0.09%Co 2 Al 9 and 0.48%Co 2 W 4 After C powder is wet-milled and mixed evenly, it is spray-dried to make a mixture, and then pressed to make a compact. After liquid-phase sintering at 1500°C, the compact was cooled from the sintering temperature to 800°C at a cooling rate of 30°C / min for 25 hours of heat preservation and aging treatment; finally, it was slowly cooled to room temperature to obtain γ'(Co 3 (Al,W)) phase strengthened Co binder phase of high heat resistance, high strength cemented carbide.

Embodiment 3

[0028] Embodiment 3: the mass percentage is 93.29%WC and 5.84%Co powder and mass percentage is 0.15%Co 4 Al 13 and 0.72%Co 3 W 6 After C powder is wet-milled and mixed evenly, it is spray-dried to make a mixture, and then pressed to make a compact. After liquid-phase sintering of the compact at 1500°C, it is then cooled from the sintering temperature to 900°C at a cooling rate of 50°C / min, and subjected to heat preservation and aging treatment for 10 hours; finally, it is slowly cooled to room temperature to obtain γ'(Co 3 (Al,W)) phase strengthened Co binder phase of high heat resistance, high strength cemented carbide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com