Method for treating refractory wastewater by virtue of supercritical water oxidation technology

A supercritical water oxidation and technical treatment technology, applied in the field of refractory wastewater treatment, can solve the problems of ammonia nitrogen, COD difficult to meet the discharge standard, complex treatment process, large area, etc., to achieve no secondary pollution, process flow Short, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

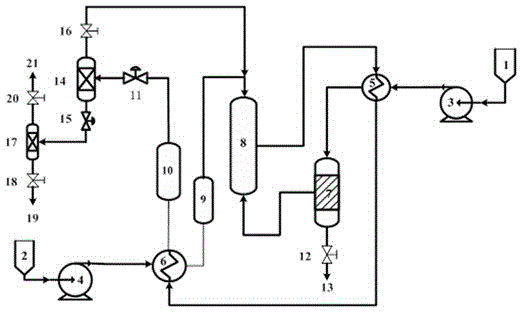

[0029] The high-concentration coal gasification wastewater containing high concentrations of ammonia nitrogen, phenols, COD and inorganic salts was treated with supercritical water oxidation. The raw water quality of the wastewater used is shown in Table 1. The wastewater in the wastewater storage tank 1 is pressurized to 24MPa by the high-pressure pump 3 and input to the heat exchanger 5 for preheating. After the wastewater is preheated to 360°C, it flows into the salt separator 7 with a temperature of 650°C for desalination; at the same time, the oxidant is sent from the storage tank 2 The high-pressure pump 4 pressurizes to 24MPa and enters the heat exchanger 6 for preheating, and the oxidant heated to 640°C by the heater 9 and the desalted waste water respectively flow into both ends of the supercritical water oxidation reactor 8 for supercritical water oxidation reaction. The amount of oxidant used is 4 times of the theoretical oxygen demand, the residence time of the was...

Embodiment 2

[0031] The high-concentration coking wastewater containing high concentrations of ammonia nitrogen, phenols, COD and inorganic salts was treated with supercritical water oxidation. The raw water quality of the wastewater used is shown in Table 1. The wastewater in the wastewater storage tank 1 is pressurized to 25MPa by the high-pressure pump 3 and input to the heat exchanger 5 for preheating. After the wastewater is preheated to 355°C, it flows into the salt separator 7 with a temperature of 650°C for desalination; at the same time, oxygen is sent from the storage tank 2 The high-pressure pump 4 pressurizes to 25MPa and enters the heat exchanger 6 for preheating. The oxidant heated to 650°C by the heater 9 and the desalted waste water respectively flow into both ends of the supercritical water oxidation reactor 8 for supercritical water oxidation. reaction. The amount of oxidant used is 5 times of the theoretical oxygen demand, the residence time of the waste water in the sup...

Embodiment 3

[0033]The high-concentration cotton textile printing and dyeing wastewater containing ammonia nitrogen, COD and inorganic salts was treated with supercritical water oxidation. The raw water quality of the wastewater used is shown in Table 1. The waste water in the waste water storage tank 1 is pressurized to 25 MPa by the high pressure pump 3 and input into the heat exchanger 5 for preheating. At the same time, the hydrogen peroxide solution is pressurized from the storage tank 2 to 25MPa by the high-pressure pump 4 and input into the heat exchanger 6 for preheating, and the oxidant and the desalted waste water heated to 500°C by the heater 9 are sent to the supercritical water oxidation reactor respectively. 8 flow in at both ends to carry out the supercritical water oxidation reaction. The amount of oxidant used is 2.5 times of the theoretical oxygen demand, the residence time of the waste water in the supercritical water oxidation reactor 8 is 20 seconds, and the system pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com