An anti-explosion fuel tank

A fuel tank and box body technology is applied in the field of explosion suppression fuel tanks, which can solve the problems of blocked refueling, jumping guns, and the explosion-proof effect needs to be improved, and achieves smooth refueling, not easy to jump guns, and good functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

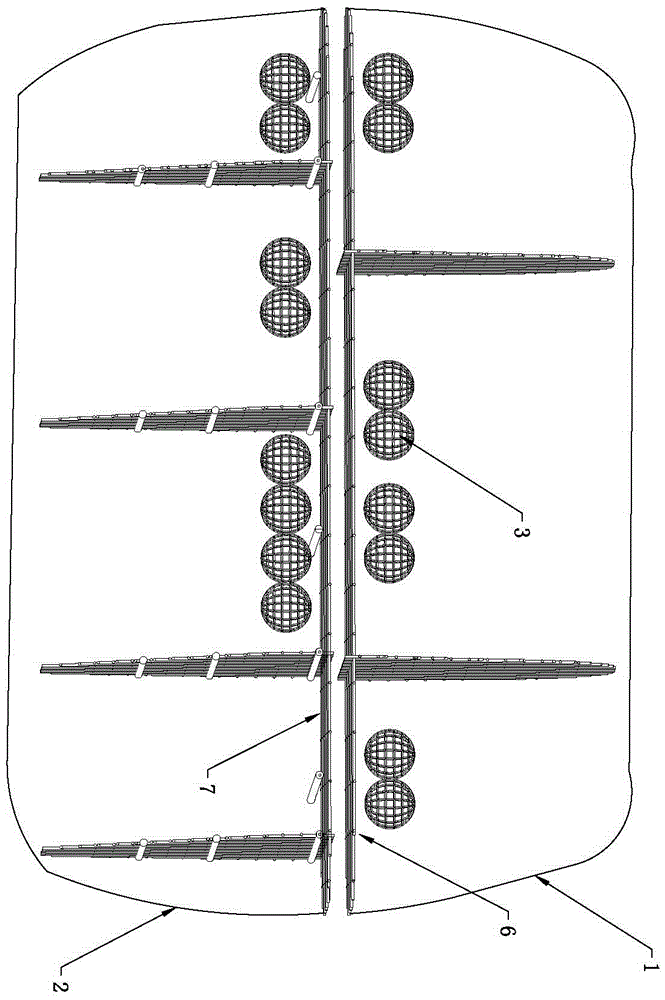

[0036] Such as figure 1 As shown, an anti-explosion fuel tank of this embodiment includes a case body, a plurality of anti-explosion bodies 3 filled in the case body, and a grid protective cover (not shown in the figure) set outside the oil level sensor, which can not only It effectively prevents the oil level sensor from being stuck by the explosion suppression body 3 filled in the tank and thus affects its normal operation, and ensures that the oil level display is sensitive, so that the oil level can be grasped in time, and it is convenient for people to drive normally.

[0037] At the same time, the box body is provided with a grille 5 that divides the box body into two or more chambers, the explosion suppression body 3 is placed in the chamber, and the arrangement of two or more chambers is beneficial to the explosion suppression body 3 are evenly distributed in the inside of the box body, avoiding the explosion suppression body 3 gathering somewhere in the box body, whil...

Embodiment 2

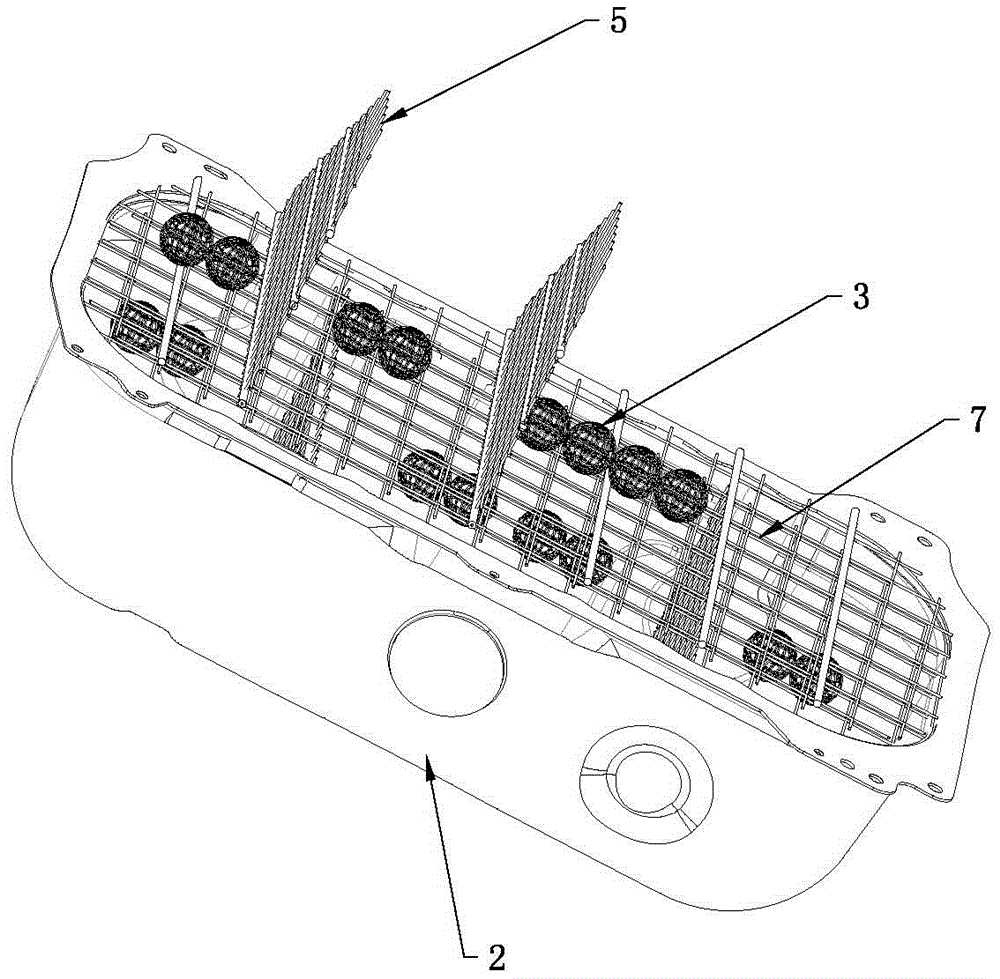

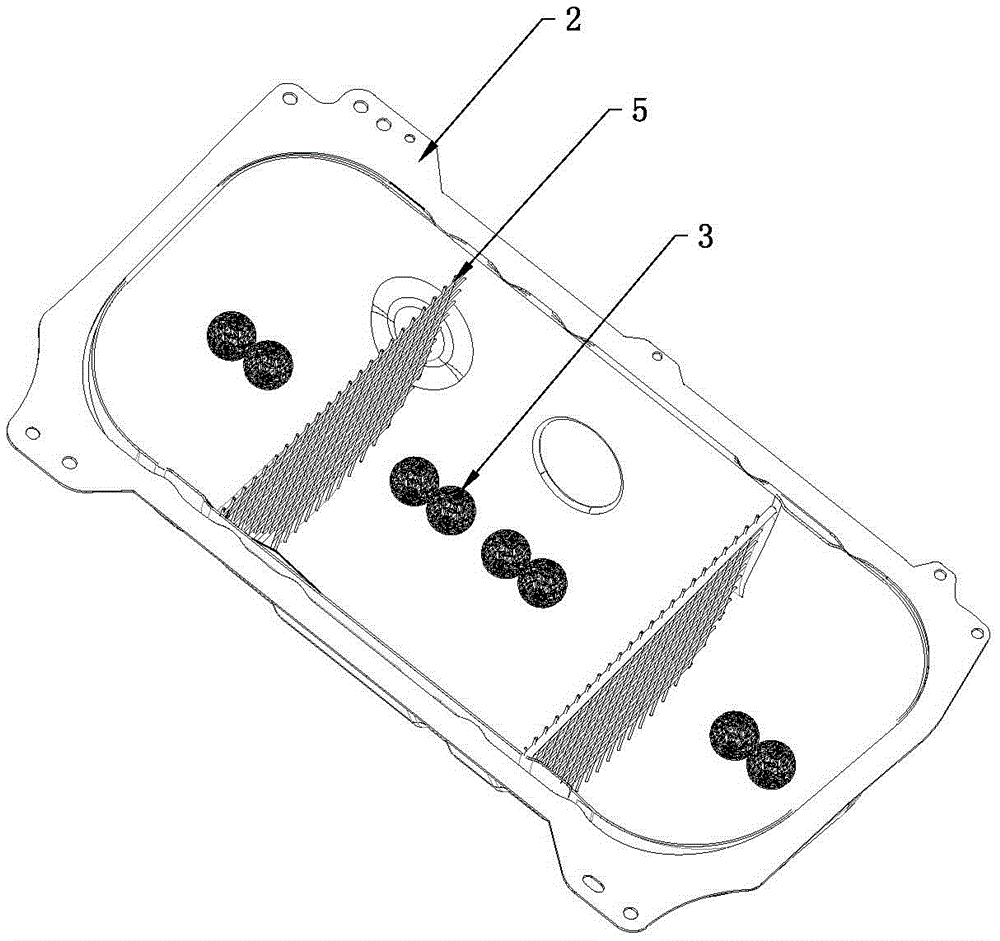

[0040] Such as Figure 2 to Figure 4As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the box body is composed of a first cover body 1 and a second cover body 2, and the first cover body 1 is provided with more than two grilles 5 and a cover set on the opening of the first cover body 1 The first screen 6 , the second cover 2 is provided with more than two grids 5 and the second screen 7 covering the opening of the second cover 2 . Wherein, the first cover body 1 is provided with a refueling port, and the refueling guard 4 is installed on the side of the refueling port facing the inside of the box.

[0041] In the embodiment, the grid 5 and the first net plate 6 in the first cover 1 are welded with the first cover 1, and the grid 5 and the second net plate 7 in the second cover 2 are all wel...

Embodiment 3

[0044] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The first cover 1 of the present embodiment is provided with two grids 5, and the first cover 1 is divided into three connected chambers by the two grids 5 and the first mesh plate 6; meanwhile, the second cover 2 A plurality of grids 5 are provided, and the second cover body 2 is divided into a plurality of connected chambers by the plurality of grids 5 and the second mesh plate 7, and the explosion suppression body 3 is installed in the aforementioned chambers. In this embodiment, according to the structure of the box body, the first cover body 1 is provided with three chambers, and the second cover body 2 is provided with multiple chambers, and the chambers are respectively filled with explosion suppressors 3. Explosion suppressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com