Rotation type four-station semisolid processing automatic production line

An automatic production line, four-station technology, used in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of low degree of automation of the production process, unreasonable process layout, and no major breakthroughs. , to achieve high-efficiency semi-solid processing operations, avoid labor-intensive, and improve mass production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

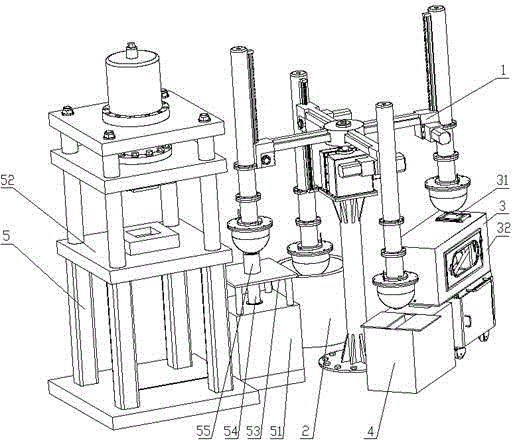

[0024] as attached figure 1 As shown, the rotary four-station semi-solid processing automatic production line of the present invention takes the rotary four-station grouting machine 1 as the center, and has four circumferential stations (the distance between two adjacent stations is 90 degrees) A resistance melting furnace 2, a semi-solid slurry preparation device 3, a crystallization incubator 4, and extrusion molding equipment 5 are arranged in sequence.

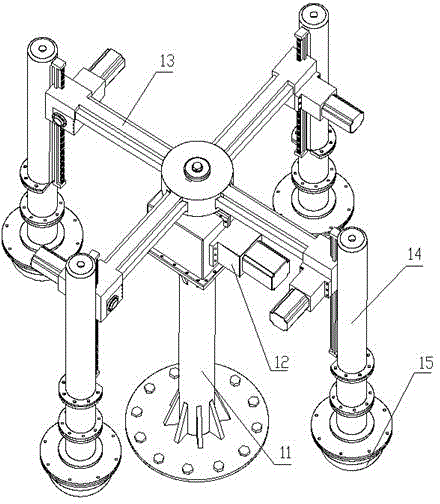

[0025] The rotary four-station grouting machine 1 is set at the center of the production line, and is mainly composed of a frame 11 , a rotary power assembly 12 , a rotary support 13 and four sets of lifting and retrieving mechanisms 14 . The rotary power assembly 12 is fixed on the top of the frame 11, and the rotary bracket 13 is arranged on the rotary power assembly 12, and is driven to rotate by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com