Energy-saving sectional roasting furnace for aluminum hydroxide balls and roasting process of energy-saving sectional roasting furnace

A technology of segmental roasting of aluminum hydroxide, applied in furnaces, vertical furnaces, furnace types, etc., to achieve good crystal form, low-cost automatic control, and unmanned production

Pending Publication Date: 2022-06-10

YANTAI BAICHUAN HUITONG TECH CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This traditional roasting method has defects such as high energy consumption of equipment, large loss of metal parts and saggers under high temperature conditions of kiln cars and mesh belt furnaces, and high labor costs for transferring materials;

2. Since aluminum hydroxide balls are roasted in the furnace, it is necessary to use a high-temperature resistant carrier (saggar). The carrier has a large volume and a large number, and the roasting process of aluminum hydroxide balls is carried out simultaneously, which also causes thermal energy loss. A large amount of loss, high energy consumption in the roasting process, especially the high non-functional consumption, resulting in high roasting costs;

3. The traditional horizontal furnace is currently the main equipment for roasting aluminum hydroxide balls. The equipment occupies a large area, many operators, a large amount of material transfer work, low heat energy utilization rate, high energy consumption, and high production costs.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

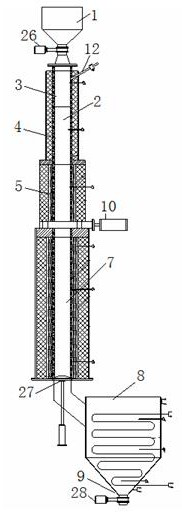

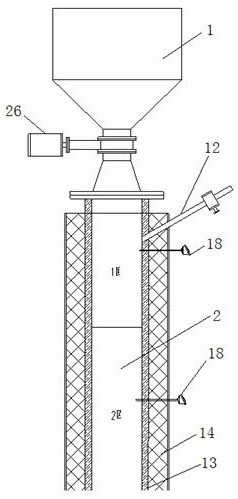

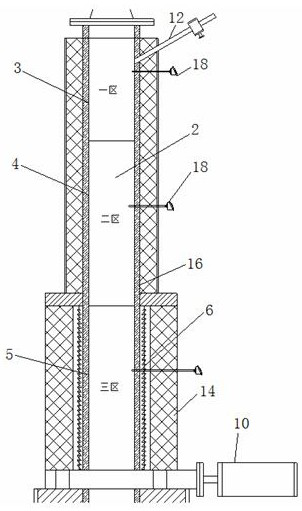

The invention relates to an energy-saving sectional roasting furnace for aluminum hydroxide balls and a roasting process of the energy-saving sectional roasting furnace, and belongs to the technical field of aluminum hydroxide ball roasting equipment. Comprising a vertical roasting furnace body, the roasting furnace body comprises a feeding bin, a preheating bin, a heating bin and a cooling bin which are arranged from top to bottom, a discharging port is formed in the bottom of the cooling bin, a first gate valve is arranged between the preheating bin and the heating bin, and whether aluminum hydroxide balls enter the heating bin from the preheating bin or not is determined through opening and closing of the first gate valve; a first gate valve is installed on the feeding bin, a micropore is formed in the first gate valve, a second gate valve is installed between the feeding bin and the preheating bin, a plunger type isolating valve is installed between the heating bin and the cooling bin, a third gate valve is installed on the discharging port, and temperature measuring mechanisms are arranged on the preheating bin, the heating bin and the cooling bin. The roasting device is good in roasting effect, compact and simple in structure, high in heat energy utilization rate and capable of greatly reducing the labor intensity of workers and reducing the production cost of enterprises.

Description

technical field [0001] The invention relates to an energy-saving segmental roasting furnace for aluminum hydroxide balls and a roasting process thereof, which is particularly suitable for roasting aluminum hydroxide balls in the preparation of palladium catalyst alumina ball carriers, and belongs to the technical field of aluminum hydroxide ball roasting equipment. Background technique [0002] At present, in the domestic production process of precious metal palladium catalyst carrier alumina balls, the roasting of aluminum hydroxide balls is an important process in the production process of alumina balls, and it is also an important link in the production process of output, quality and energy consumption control. At present, the roasting of aluminum hydroxide balls is usually produced through a horizontal furnace (tunnel type, belt roaster). The aluminum hydroxide balls are first manually loaded into the sagger, and then the sagger loaded with materials is placed at the entr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B1/04F27B1/20F27B1/24F27B1/28

CPCF27B1/04F27B1/20F27B1/24F27B1/28

Inventor 张红张晓伟邓世盟张洪超其他发明人请求不公开姓名

Owner YANTAI BAICHUAN HUITONG TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com