Method for testing heat insulation temperature of thermal barrier coating

A thermal barrier coating and coating technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of no comparison sample, short heating time, inability to test the thermal barrier coating thermal insulation temperature well, etc. Intuitive and precise thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

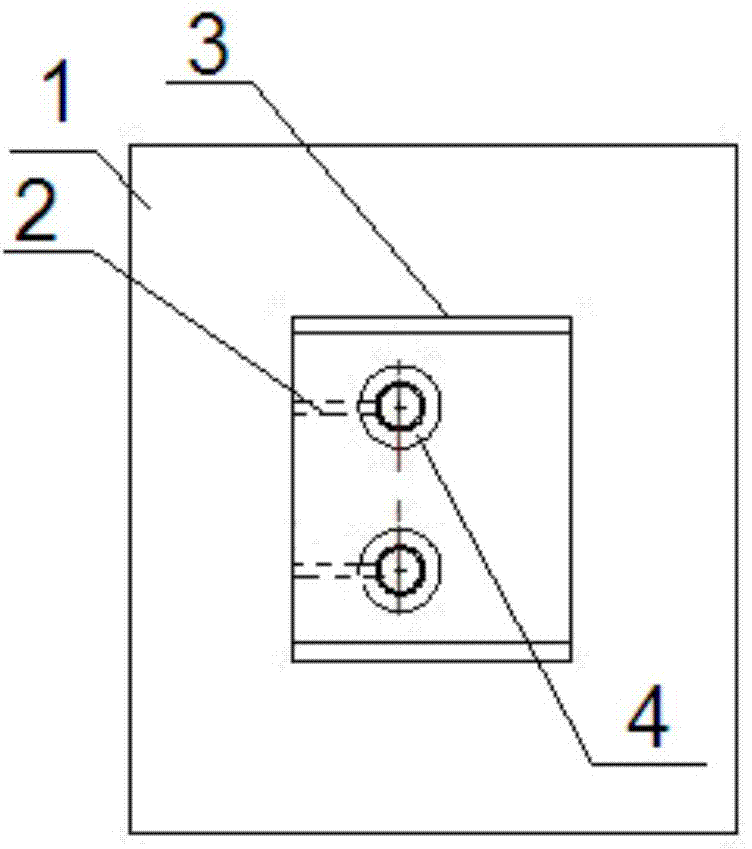

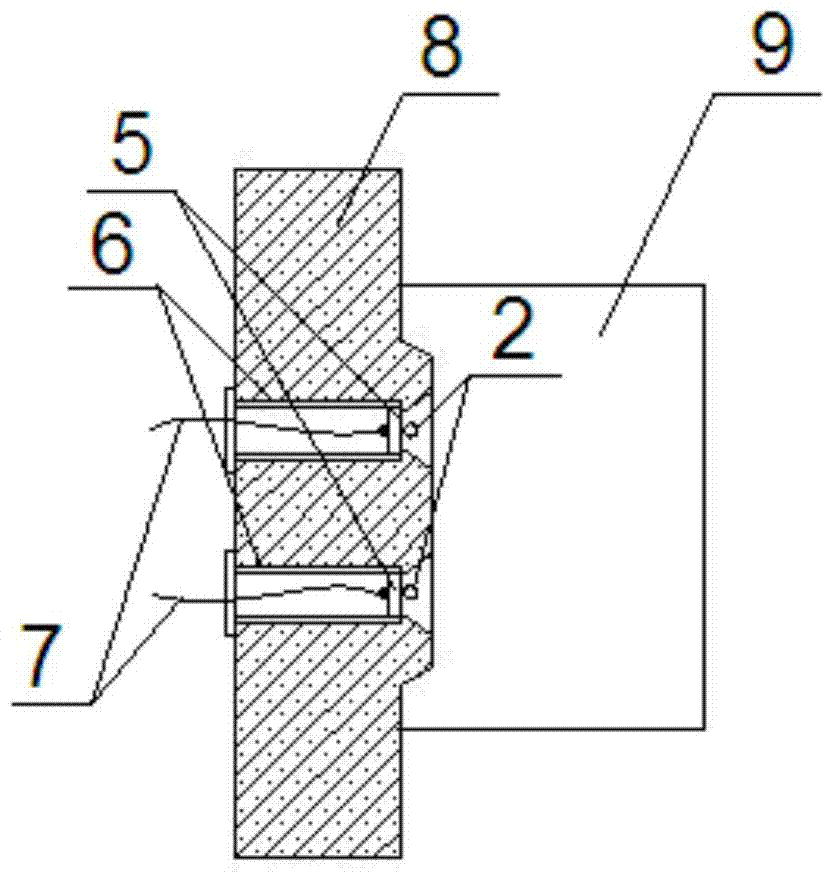

[0023] Such as figure 1 , figure 2 As shown, the experimental device of the present invention is a commonly used resistance furnace (the electric heating element can be a silicon carbon rod or a silicon molybdenum rod), and an improved heat-insulated furnace door is adopted, including a furnace door 1, and the furnace door insulation material 8 is fiber For aluminum silicate, a boss 3 is provided inside the furnace door (the side facing the furnace 9). Two through holes are drilled on the boss to the outside of the furnace door, and the ceramic tube 6 is embedded into the hole from the outside of the door. The sample 5 is installed in the The end of the ceramic tube 6 is fixed at the position of the bell mouth 4 close to the through hole. The bell mouth in front of the sample is provided with an S-type thermocouple 2 (passed through from the side of the boss 3), and a K-type thermocouple is welded at the center of the back of the sample. thermocouple7.

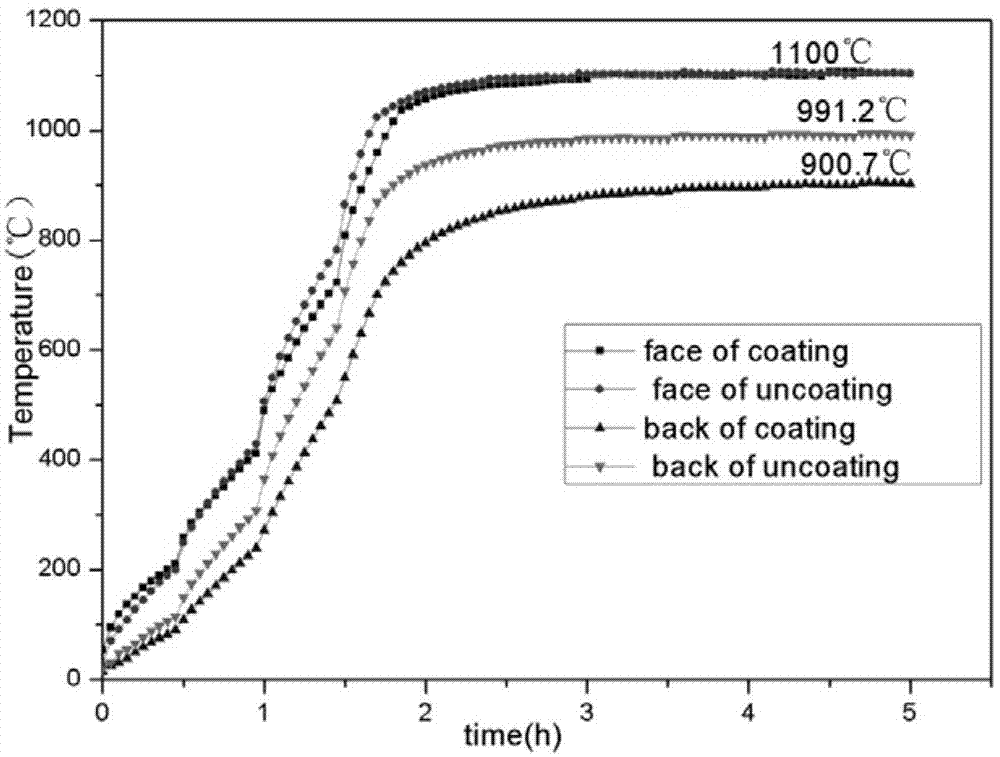

[0024] Prepare two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com