A parallel core holder

A technology of core holder and parallel connection, which is applied in the direction of instruments, scientific instruments, suspension and porous material analysis, etc., and can solve problems such as inconvenient use, large deviation of measurement results, and poor simulability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

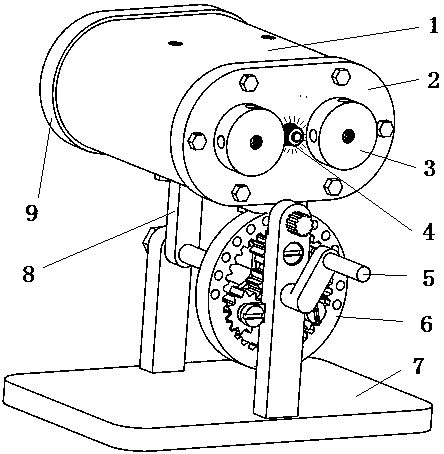

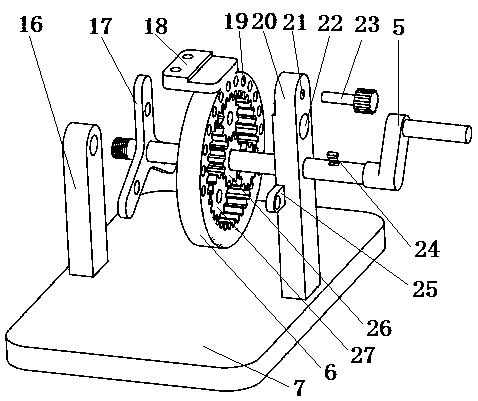

[0044] Assemble the holder into a ready-to-work state, connect the oil inlet pipeline to the upper oil inlet 29 of the parallel cylinder 1, and connect the oil drain pipeline to the oil drain 32 at the lower part of the parallel cylinder 1; insert two kinds of rock cores into the parallel cylinder 1 In the rubber cylinder 11 of the working cavity, a flow control device composed of a square valve sleeve 12 and a square valve core 13 is inserted into the square through hole 30 of the parallel cylinder body 1, and the front end cover 2 and the rear end cover 9 are fixed on the parallel connection through screws. Screw the plug 3 into the front and rear ends of the cylinder 1, tighten the plug 3 through the loading and unloading groove 15 on the plug 3, push the square valve core 13 to the bottom and screw the fine-tuning nut 4 on the cylindrical rod 40 , record the corresponding dial value when the fine-tuning nut 4 is just close to the end face of the front end cover 2, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com