A Dynamic Model Method and Its Application for Measuring the Air Resistance Coefficient of High-Speed Train Tunnels

A technology of tunnel air and drag coefficient, which is used in aerodynamic tests, measuring devices, and testing of machine/structural components. Simple operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

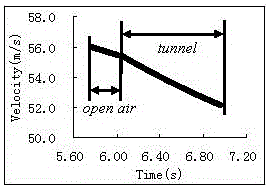

[0079] On the high-speed train dynamic model test platform, test the air resistance coefficient of the intercity EMU model, the specific steps are as follows:

[0080] a, the EMU model is the model of the 1:16.8 intercity EMU with 3 sections, and the quality is 23 kilograms. The EMU model is placed on the rail of the dynamic model test bench with tunnel, and connected with the acceleration mechanism;

[0081] b. The tunnel of the dynamic model test bench with tunnel is 50 meters long, and a light reflection belt with a length of 73 meters and a width of 2cm is set between the two tracks; the length of the light reflection belt is 20 meters before the tunnel entrance, and the tunnel 3 meters behind the exit; the light reflection belt is composed of a group of black line segments with a length of 10cm and a group of white line segments with a length of 10cm alternately connected in black and white; the black segment is required to be darker in color, with a rough surface, and try...

Embodiment 2

[0101] It is basically the same as Embodiment 1, except that a real vehicle is used.

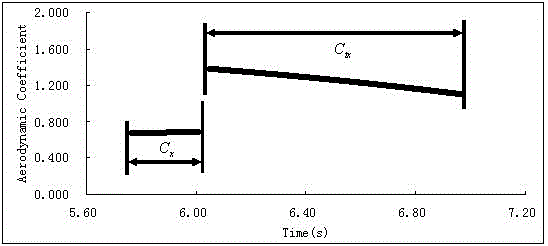

[0102] The calculation method for calculating the air resistance coefficient of the tunnel is as follows:

[0103] Substitute the mass, velocity and acceleration of the tested train into Newton's second law formula and Davis empirical formula:

[0104] Newton's second law formula: the total resistance of the tested train = the mass of the tested train × acceleration

[0105] Davis empirical formula: the total resistance of the tested train = tunnel air resistance + wheel-rail friction resistance + resistance caused by ventilation such as air conditioning; among them,

[0106] Tunnel air resistance = 0.5 × air density × square of speed × cross-sectional area of the tested train × tunnel air resistance coefficient;

[0107] Wheel-rail frictional resistance: proportional to the mass of the actual vehicle;

[0108] The resistance caused by the ventilation of the air conditioner: it is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com