Spray type air conditioner and air conditioning method

An air-conditioning equipment and spray-type technology, which is applied in the field of air purification equipment and air purification, can solve the problems of increasing the cost of purchasing electrical appliances, the inability of air purifiers to remove pollutants, and the low efficiency of pollutants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

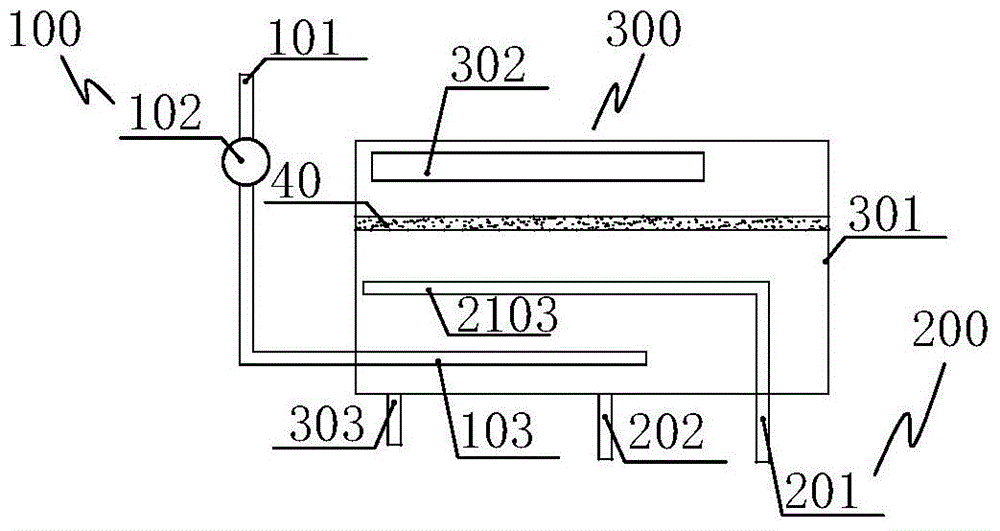

[0108] refer to figure 1 , figure 1 It is a schematic diagram of the first embodiment of the spray air conditioner of the present invention. The spray air conditioner of the present invention includes a first air conditioner, and the first air conditioner includes a first air system 100 , a first spray liquid system 200 , and a first box system 300 . The first box system 300 includes a first box 301, the first box 301 is provided with a treated air outlet 302, specifically, the treated air outlet 302 is arranged on the top of the first box 301, for the processed Air out. The first air system 200 is used to transport the air to be treated into the first box 301 . The first spray liquid system 200 is used to deliver the first liquid to the first tank 301, spray the air delivered to the first tank and discharge the first liquid in the first tank, when the air to be treated and the first tank When a liquid contacts in the first tank 301, the first liquid reacts or interacts wi...

no. 2 example

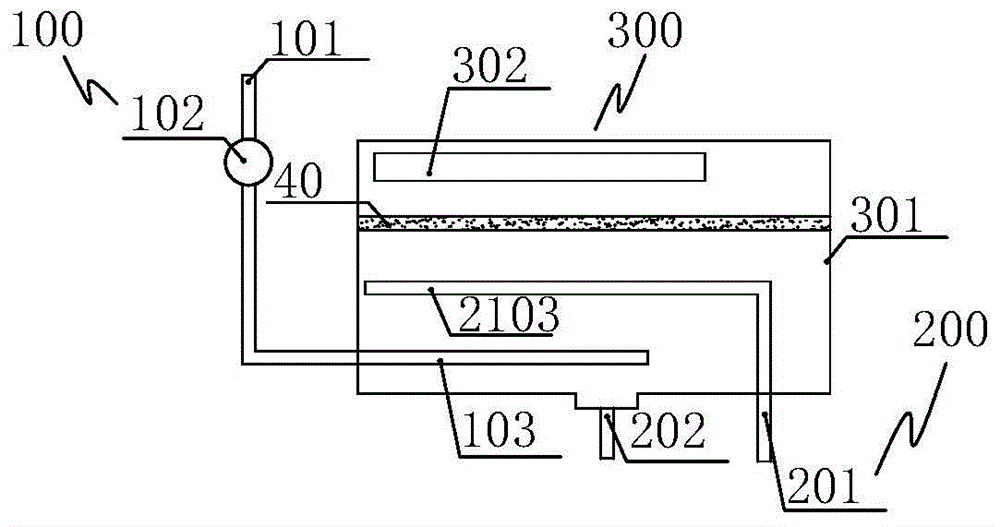

[0133] refer to figure 2 , figure 2 It is a schematic diagram of the second embodiment of the spray air conditioner of the present invention. The spray air conditioner of this embodiment has substantially the same structure as that of the first embodiment, the difference is that the bottom of the first box 301 has a height structure, such as: the bottom of the first box 301 corresponds to The position of the sediment discharge port 303 has a recessed portion, that is to say, the bottom of the first box 301 is lower than the area of the sediment discharge port 303 , and the sediment in the liquid will gather in the low place, which is beneficial to discharge the sediment. The structure of this embodiment is the same as that of the first embodiment and will not be repeated here.

no. 3 example

[0135] refer to image 3 , image 3 It is a schematic diagram of the third embodiment of the spray air conditioner of the present invention. The spray air conditioner of this embodiment has substantially the same structure as the spray air conditioner of the first embodiment, the difference is that the sediment discharge port 303 is not provided at the bottom of the first box body 301, but The bottom of the body 301 has a recess corresponding to the position of the liquid outlet 202, that is to say, the bottom of the first box body 301 is lower than the area corresponding to the liquid outlet 202, and the sediment in the liquid will gather in the low place. When the liquid is discharged, the sediment Can be discharged at the same time, which is beneficial to discharge sediment. The structure of this embodiment is the same as that of the first embodiment and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com