Preparation of maltodextrin with low de value by jet liquefaction enzyme method

A technology of maltodextrin and injection temperature, which is applied in the field of maltodextrin preparation, can solve the problems of single product variety, lack of low DE value, and unstable product quality, and achieve good solubility, good heat absorption performance, and convenient The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

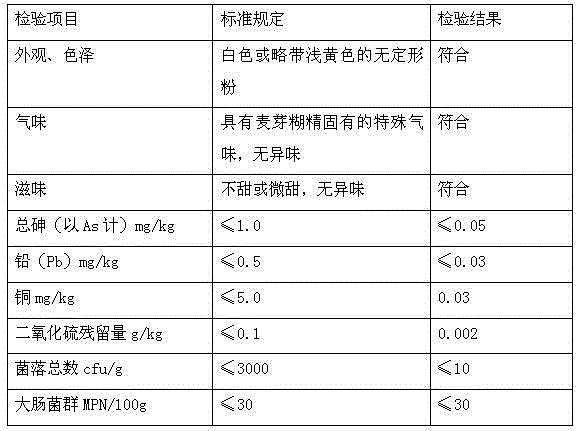

Examples

Embodiment 1

[0032] The preparation method of the maltodextrin of low DE value comprises the following steps:

[0033] (1) Prepare raw corn flour: crush it to 300 mesh; adjust the corn flour into starch milk with a concentration of 30% by mass, heat to 50°C, cool to room temperature, and adjust its pH value to 4; Bacillus stearotherimi α-amylase is contacted, and the amount of enzyme added is 4% of the corn flour quality, stirred evenly; then the activator potassium chloride is added, and its addition is 1% of the corn flour;

[0034] (2) Injection liquefaction: use a low-pressure injector with material and gas, the material pressure is 0.3Mpa, the first injection temperature is 105-110°C, and the injection time is 10min. After the first injection, maintain 95°C for 80min and control DE The value is 14-20%, the second injection temperature is 155°C, and the injection time is 5 minutes;

[0035] (3) Microporous refining: After the second injection, cool the liquefied liquid below 90°C, add...

Embodiment 2

[0051] The preparation method of the maltodextrin of low DE value comprises the following steps:

[0052] (1) Prepare raw corn flour: crush it to 200 mesh; adjust the corn flour into starch milk with a concentration of 20% by mass, heat to 45°C, cool to room temperature, and adjust its pH value to 3; Bacillus stearotherimi α-amylase is contacted, and the amount of enzyme added is 1% of the corn flour quality, and stirred evenly; then sodium chloride is added, and the addition of sodium chloride is 0.5% of the corn flour;

[0053] (2) Injection liquefaction: adopt a low-pressure injector with material and gas, the material pressure is 0.3Mpa, the first injection temperature is 105°C, and the injection time is 8 minutes. After the first injection, maintain 95°C for 60 minutes, and control the DE value to 14 %, the temperature of the second injection is 150°C, and the injection time is 5 minutes;

[0054] (3) Microporous refining: After the second injection, cool the liquefied l...

Embodiment 3

[0060] The preparation method of the maltodextrin of low DE value comprises the following steps:

[0061] (1) Prepare raw corn flour: crush it to 400 mesh; adjust the corn flour into starch milk with a concentration of 40% by mass, heat to 60°C, cool to room temperature, and adjust its pH value to 5; Bacillus stearothermus α-amylase contact, the amount of added enzyme is 5% of the corn flour quality, stir evenly; then add activator, the addition of the activator is 0.5-2% of corn flour;

[0062] (2) Injection liquefaction: A low-pressure injector with gas is used, the material pressure is 0.3Mpa, the first injection temperature is 110°C, and the injection time is 12 minutes. After the first injection, maintain 95°C for 90 minutes, and control the DE value to 20 %, the temperature of the second injection is 160°C, and the injection time is 5 minutes;

[0063] (3) Microporous refining: After the second injection, cool the liquefied liquid below 90°C, add activated carbon with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com