Hemp fibre filter wire and preparation method thereof

A technology of hemp fiber and filter wire, applied in the field of hemp fiber filter wire and its preparation, can solve the problems of glass fiber filter wire endangering human health, absorbent cotton filter wire not resistant to corrosion cost, restricting the development of purification and filtration industry, etc. , light weight, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

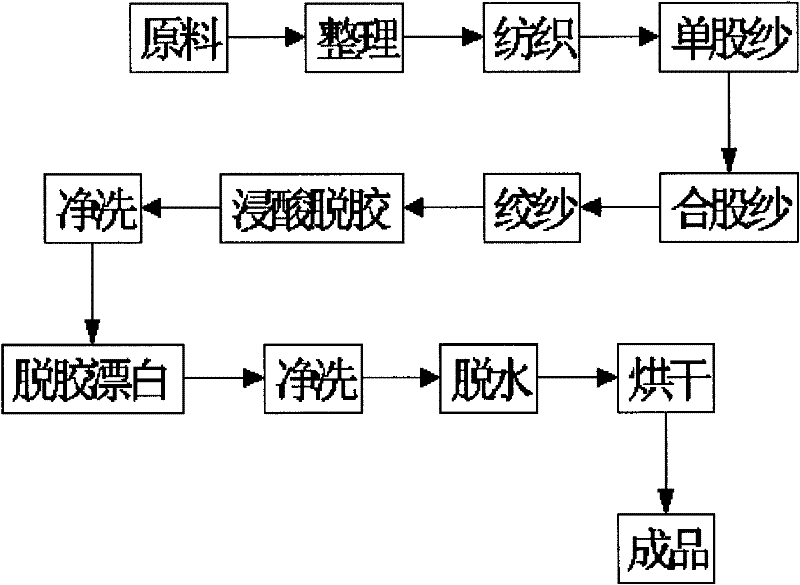

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of Cannabis Filter Line

[0050] (1) Spin the hemp fiber to be processed into a single strand, and then ply into a multi-strand yarn. The length and thickness of the yarn are made according to the requirements; in order to facilitate degumming and bleaching, the spun yarn is made A skein with a weight of about 450g.

[0051] (2) Soak the yarn in dilute sulfuric acid at 30-40°C for degumming, the bath ratio is 1:9, the soaking time is 12 hours, and then rinse with water until neutral.

[0052] (3) Put the yarn evenly into the cooking pot at room temperature, inject clean water at a bath ratio of 1:15 and then add bleach, and circulate with a pump to make the pH in the cooking pot 9.5 to 11. Warm up the yarn at a rate of 2-3°C / min, wait until the temperature reaches 65°C, then keep raising the temperature at a rate of 1°C / min until the temperature reaches 80-95°C, keep warm for 90 minutes, degumming and bleaching; put the residual liquid in In the...

Embodiment 2

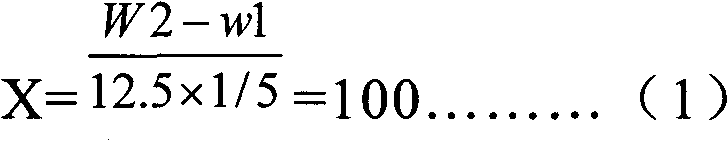

[0058] Embodiment 2: performance detection of hemp fiber filter line

[0059] Hemp fiber filter thread is tested based on relevant standards of absorbent cotton filter thread and polypropylene fiber filter thread.

[0060] (1 Scope:

[0061] This standard is used for hemp fiber filter line (for purification and filtration of various liquids).

[0062] (2) Technical requirements

[0063] ① Sensory

[0064] Pure color, uniform lines, no debris visible to the naked eye, non-toxic, no peculiar smell.

[0065] ②Quality

[0066] The mass tolerance per meter of noodles is ±0.05g.

[0067] ③ twist

[0068] The filter thread with a length of 10cm has a twist of 7 to 12 twists.

[0069] ④ powerful

[0070] 3kg load per meter without breaking

[0071] ⑤ Whiteness

[0072] The whiteness of this product should not be lower than 65 degrees.

[0073] ⑥Water absorption time

[0074] It should sink under the liquid surface within 20S.

[0075] ⑦Fluorescent substance

[0076] View...

Embodiment 3

[0109] Embodiment 3: comprehensive utilization in the preparation process of hemp fiber filter line

[0110] Some waste water will be produced during degumming and bleaching, which will have a certain impact on environmental pollution. For this reason, the following measures are proposed to solve the problem. The method is:

[0111] (1) Discharge the waste acid solution (the sulfuric acid content is about 50% of the stock solution) after soaking and degumming for the first time in the raffinate pool.

[0112] (2) Considering acid-base neutralization, it is proposed to increase the sulfuric acid content by 30% and reduce the soaking time by 40% during the first soaking degumming.

[0113] (3) Recycle the residual liquid after degumming and bleaching, put the uncooked and bleached cannabis filter line into this liquid for pre-treatment with heating, the temperature is controlled at 80-90°C, and the time is 90min, which can greatly reduce the Its chemical material content, at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com