Metal/graphite-like carbon nitride compound catalyst and preparing method thereof

A graphitic carbon nitride and composite technology, which is applied in the preparation of organic compounds, preparation of aminohydroxy compounds, catalysts for physical/chemical processes, etc., can solve the problems of easy poisoning of catalysts, expensive catalysts, and high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Gold / Graphite-like Carbon Nitride Composite

[0039] Synthetic g-C 3 N 4 and HAuCl 4 As the starting material, weigh 1.5 g of g-C 3 N 4 , add 100mL of deionized water; under the condition of stirring, add 0.6mol / L HAuCl dropwise to the above solution 4 , continue stirring for 30 minutes. An aqueous solution of hydrazine hydrate was added dropwise until the reaction was complete. Then the reaction mixture solution was separated, washed 5 times with deionized water, and dried at 80°C for 10 hours to obtain the final Au / g-C 3 N 4 product.

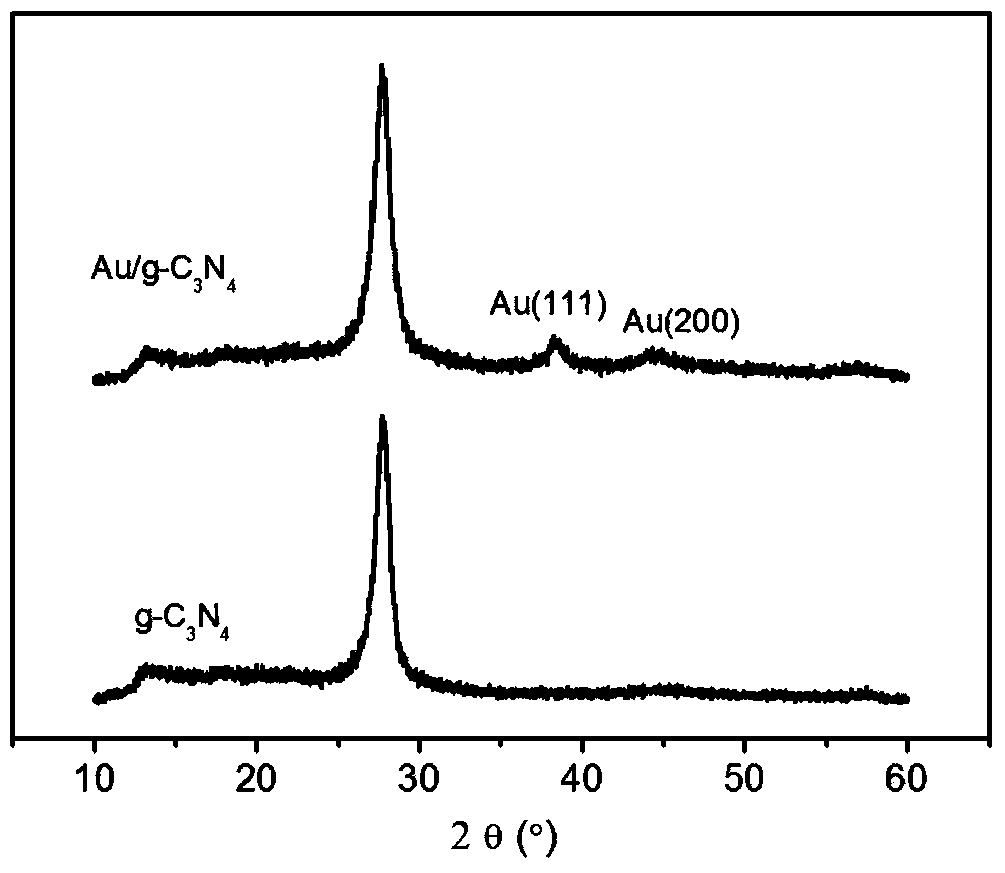

[0040] figure 1 X-ray diffraction pattern of the gold / graphitic carbon nitride composite prepared for this example. with pure g-C 3 N 4 The comparison of the X-ray diffraction pattern shows that the powder spectrum can be indexed as gold and g-C 3 N 4 phase, without the existence of other impurity phases. figure 2 with image 3 The TEM photo and high-resolution TEM photo of this sample, from which it can be s...

Embodiment 2

[0044] Example 2: Silver / Graphite-like Carbon Nitride Composite

[0045] Synthetic g-C 3 N 4 and AgNO 3 as the starting material. Weigh 1.5g of g-C 3 N 4 , add 100mL of deionized water, and add 0.8mol / L AgNO 3 , continue stirring for 30 minutes. An aqueous solution of hydrazine hydrate was added dropwise until the reaction was complete. Then the reaction mixture solution was separated, washed five times with deionized water, and dried at 80° C. for 10 hours to obtain the final product.

[0046] Figure 7 For the X-ray diffraction pattern of the carbon composite prepared in this example, the spectrum of the powder can be indicated as the phase of silver and graphite-like carbon nitride, without the existence of other impurity phases.

[0047] The Ag / g-C 3 N 4 The complex can be used as a catalyst under normal temperature and pressure. According to the above-mentioned catalytic performance test conditions, the catalytic performance curve obtained is as follows Figu...

Embodiment 3

[0048] Example 3: Platinum / Graphite-like Carbon Nitride Composite

[0049] Synthetic g-C 3 N 4 and H 2 PtCl 6 as the starting material. Weigh 1.5g of g-C 3 N 4 , add 100 mL of deionized water, and add 0.2 mol / L H 2 PtCl 6 , continue stirring for 30 minutes. An aqueous solution of hydrazine hydrate was added dropwise until the reaction was complete. Then the reaction mixture solution was separated, washed five times with deionized water, and dried at 80° C. for 10 hours to obtain the final product.

[0050] Figure 9 X-ray diffraction pattern of the carbon composite prepared for this example. Compared with the X-ray diffraction pattern of pure graphite-like carbon nitride, it can be seen that the diffraction peak of platinum in the composite pattern is very weak.

[0051] The Pt / g-C 3 N 4 The complex can be used as a catalyst under normal temperature and pressure. According to the above-mentioned catalytic performance test conditions, the catalytic performance cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com