Diameter-changing tube type air flow tobacco shred drying device based on groove type light gathering solar energy

A technology of concentrating solar energy and air drying, which is applied in the field of solar energy applications, can solve the problems of low solar radiation energy flux density, and achieve the effects of improving energy flux density, protecting the environment, and stabilizing the output temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

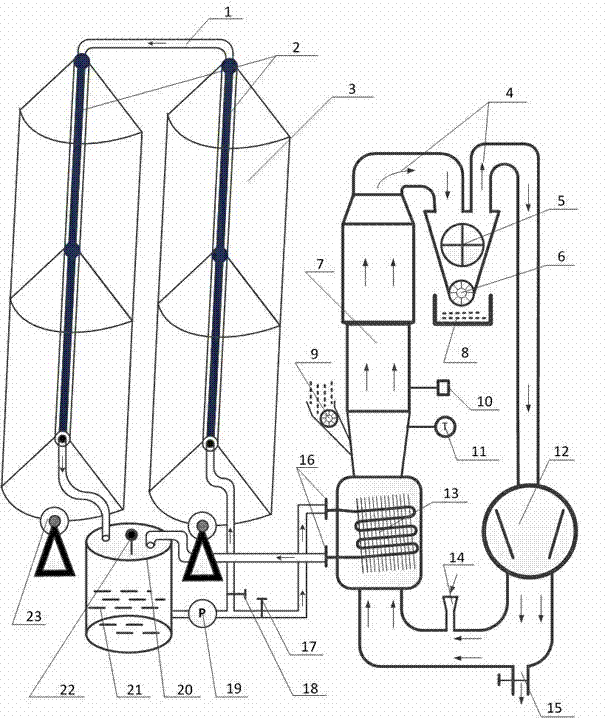

[0014] see figure 1 In the present invention, the high-efficiency reflective condenser (3) placed on the trough collector bracket (23), the high-efficiency reflective condenser (3) can gather sunlight to the vacuum metal-glass straight-through pipe (2), the circulating oil pump ( 19) Take out the heat transfer oil (21) from the heat storage and release oil tank (20), open the valve (18), transport it to the vacuum metal-glass straight-through pipe (2) through the heat preservation oil pipe (1) for heating, and pass through the heat storage and release oil tank The temperature sensor (22) in (20) measures the oil temperature, heats it to a predetermined temperature, and then opens the valve (17), and the heat transfer oil (21) enters the liquid-gas connection connected by the flange (16) through the heat preservation oil pipe (1). The heat exchanger (13) exchanges heat with the process gas (4), and the heat transfer oil (21) after heat exchange is recycled to the heat storage ...

Embodiment 2

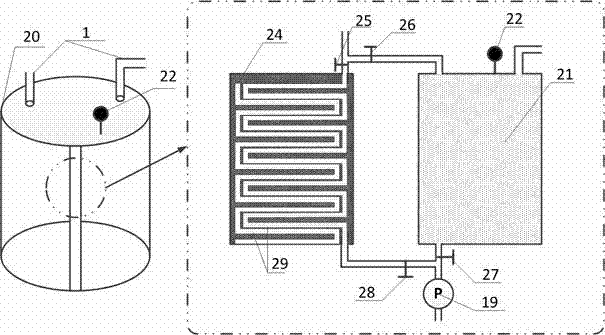

[0016] see figure 1 , figure 2 , the difference between this embodiment and Embodiment 1 is that this embodiment will open the valve (25) in the heat storage and release oil tank (20) under sunny weather conditions, and the heat transfer oil (21) will pass through the heat exchange pipe (29) to The energy is stored in the phase change energy storage material (24). When the unstable weather factors are affected, the valve (25) and the valve (28) are opened, the phase change energy storage material (24) starts to release energy, and the heat transfer oil (21) is changing Heating to the design temperature in the heat pipe (29) can ensure a stable energy supply to the liquid-gas-air heat exchanger (13) and ensure the normal operation of the shredded tobacco drying device. Since the rest of this embodiment is the same as that of Embodiment 1, it will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com