Ceramic diaphragm, and preparation method and application thereof

A ceramic diaphragm and diaphragm material technology, applied in electrical components, electrochemical generators, circuits, etc., can solve problems such as loss of isolation function, easy fire, and difference in diaphragm performance, so as to reduce VOC emissions, reduce fire risks, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 20g of alumina to 80g of water-soluble polyvinylidene fluoride, add an appropriate amount of water, and disperse at a high speed with a stirrer at a speed above 100rpm. During the dispersion process, add 0.1-3% of the weight of the ceramic particles. )-based phenol polyoxyethylene ether, and polyethylene glycol polyols accounting for 0.1-3% of the weight of the ceramic particles. After the dispersed slurry is stirred for 30-60 minutes, it is subjected to vacuum defoaming treatment to obtain a protective layer slurry;

[0030] The protective layer is coated on the base material of the diaphragm material, and then dried to form a coil of ceramic diaphragm film, and finally cut into finished ceramic diaphragm coils of various width specifications.

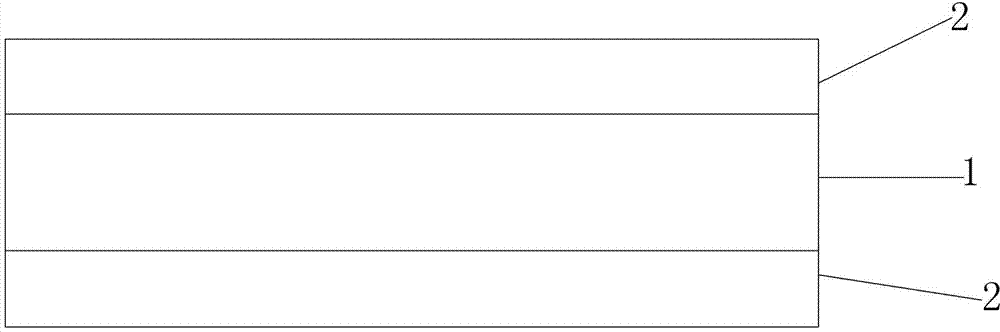

[0031] Such as figure 1 As shown, the intermediate layer of the ceramic diaphragm prepared above is the diaphragm material substrate 1, and the diaphragm material substrate

[0032] The material is a porous film layer made...

Embodiment 2

[0034] Add 30g of alumina to 70g of water-soluble acrylic resin, and add an appropriate amount of water, and use a stirrer to disperse at a speed of more than 100rpm at a high speed. During the dispersion process, add a defoamer accounting for 0.1-3% of the weight of the ceramic particles, and The dispersant accounts for 0.1-3% of the weight of the ceramic particles, and after the dispersed slurry is stirred for 30-60 minutes, it is subjected to vacuum defoaming treatment to obtain a protective layer;

[0035] The protective layer is coated on the base material of the diaphragm material, and then dried to form a coil of ceramic diaphragm film, and finally cut into finished ceramic diaphragm coils of various width specifications.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com