Ultra-thin encoder of permanent magnet servo high-speed motor

A high-speed motor and encoder technology, applied in the field of encoders, can solve the problems of irreplaceable, large installation space, inconvenient and fast installation and adjustment, etc., and achieves high installation and positioning accuracy, small installation space, and convenient and fast installation and adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

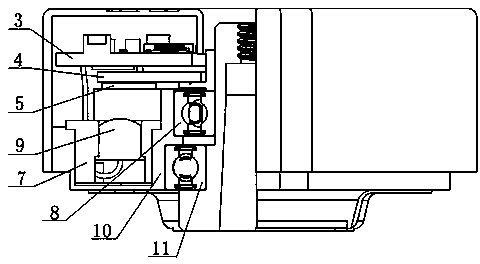

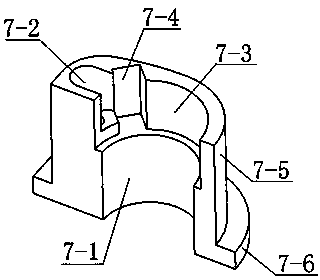

[0015] attached by figure 1 , 2 As shown: the encoder includes a casing 1, a rubber molded wire sheath 2, a circuit board with electrical components 3, a moving grating 4, a fixed grating 5, a moving grating seat 6, a light-emitting diode sleeve 7, and a first bearing 8 , light emitting diode 9, main body support 10, second bearing 11, hollow shaft 12 and plate spring 13, described circuit board 3 with electrical components, moving grating 4, fixed grating 5, moving grating seat 6, light emitting diode The pipe sleeve 7, the first bearing 8, the light emitting diode 9, the main body support 10, the second bearing [11 and the hollow shaft 12 are assembled to form the main body of the encoder, the shell 1 is set on the outside of the main body of the encoder, and the leaf spring 13 is arranged on the Below the main body of the device, the rubber molding grommet 2 is arranged on the side of the casing 1, and the light-emitting diode 9 is set in the light-emitting diode tube cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com