Two-stage flash evaporator of waste heat power generation system of cement kiln

A technology of waste heat power generation and two-stage flash evaporation, which is used in waste heat treatment, steam generation, steam engine installations, etc., can solve the problems of excess, the heat source cannot be fully utilized, and the economic benefits of waste heat recovery cannot be guaranteed, so as to improve heat utilization. High efficiency, simple system and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

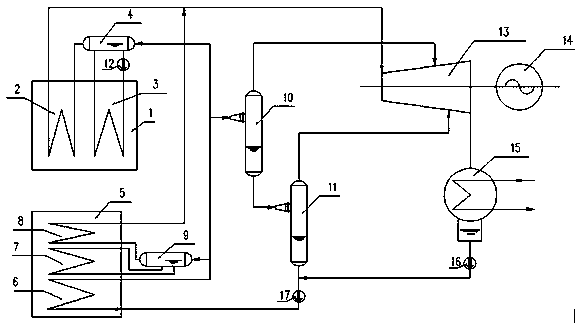

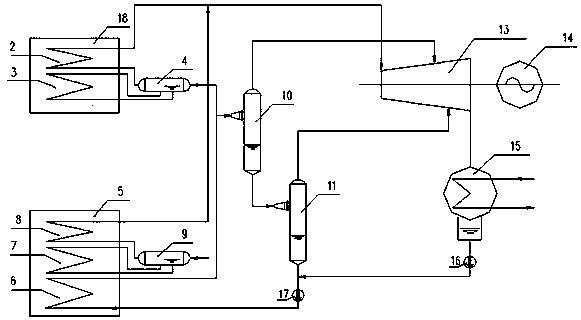

[0017] exist figure 1 with figure 2 In the two-stage flash evaporator described in the present invention, the two flash evaporators are connected in series, the economizer 6 is connected to the water inlet of the primary flash evaporator 10 through a pipeline, and the water outlet of the primary flash evaporator 10 is connected to the secondary flash evaporator The water inlets of 11 are connected, the water outlet of the secondary flash evaporator 11 is connected to the boiler feed water pump 17, and the steam outlets of the primary flash evaporator 10 and the secondary flash evaporator 11 respectively lead to the rear stage of the steam turbine 13 to perform work.

[0018] During work, the high-temperature water heated by the economizer 6 is sent to the AQC furnace drum 5, the PH furnace drum 4 (or the SP furnace drum 18) and the first-stage flash evaporator 10 respectively. The high-temperature water entering the primary flash evaporator 10 generates saturated steam under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com