Aluminum alloy chemical milling waste liquid treatment method, process and system

A treatment process and treatment system technology, applied in the field of metal processing waste liquid treatment, can solve the problems of not really achieving recycling, huge expenditures of enterprises, environmental damage, etc., to save treatment costs, stabilize processing parameters, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

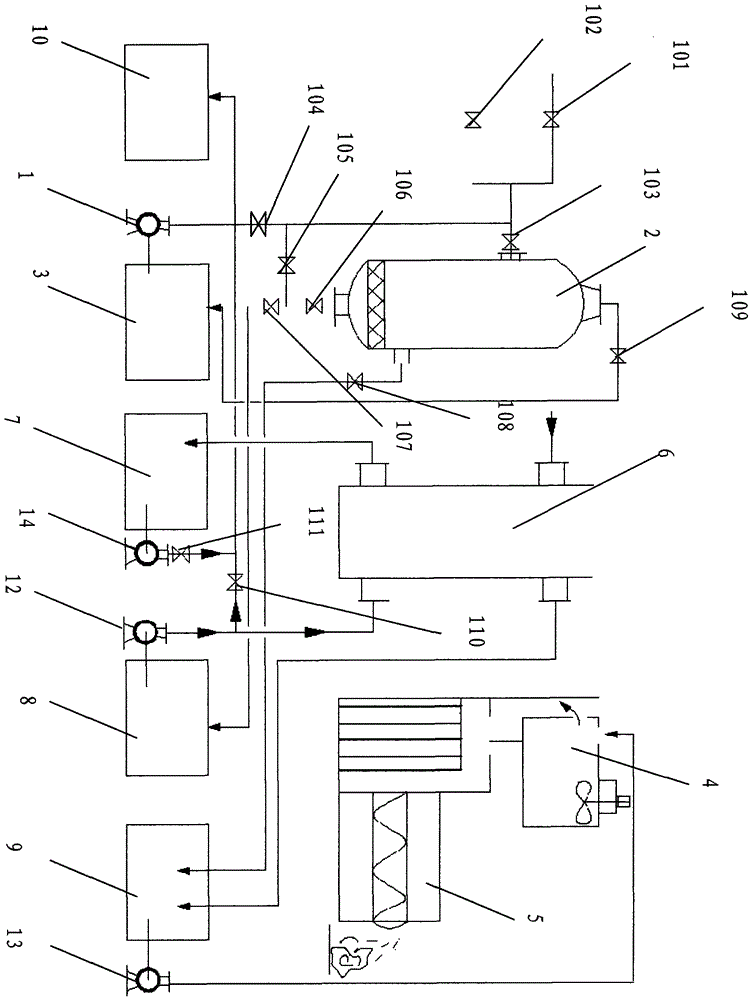

Method used

Image

Examples

Embodiment 1

[0066] Preferred embodiment 1: The operating pressure of the selected membrane separator 2 is 0.3Mpa, and the temperature is 50°C;

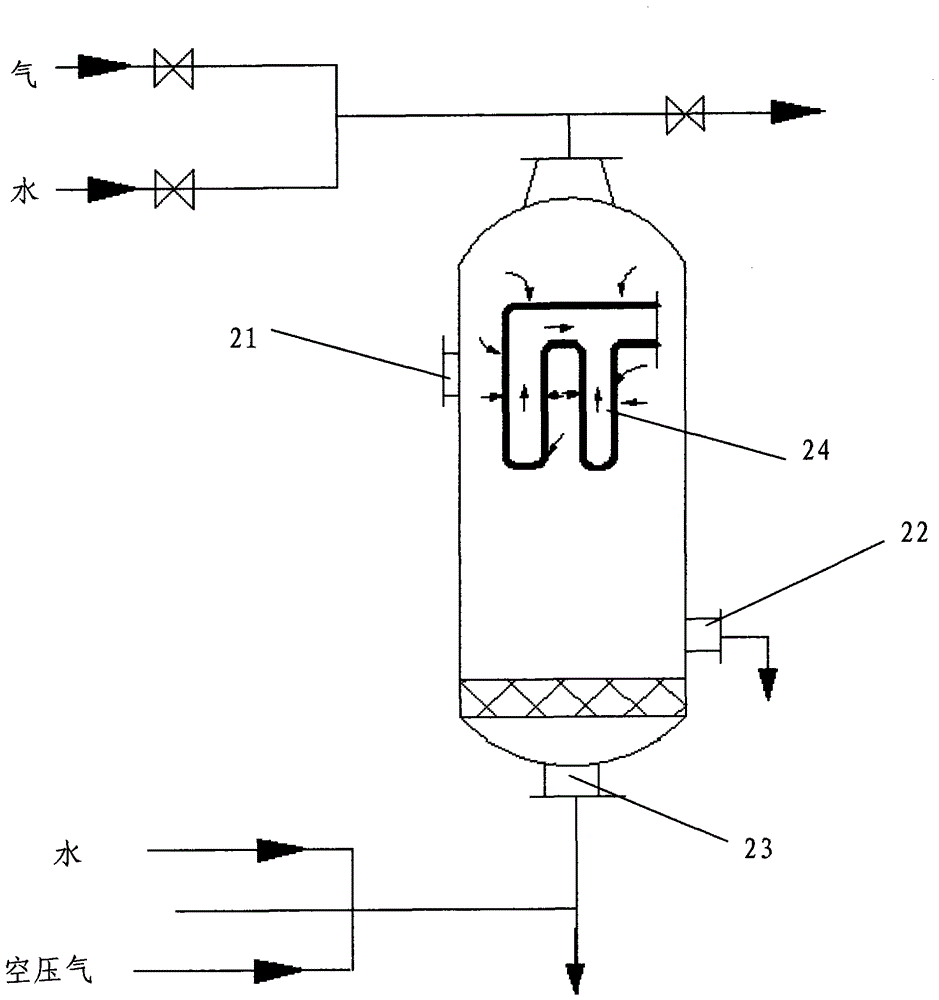

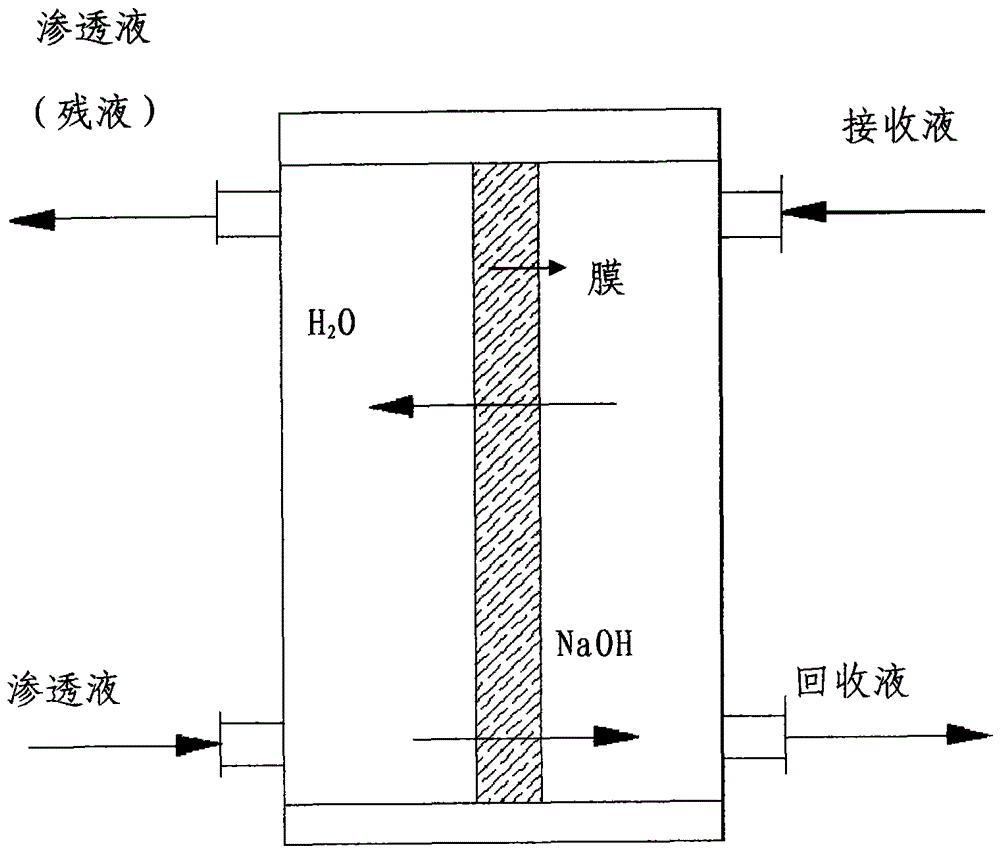

[0067] a. The chemical milling waste liquid is transported into the membrane separator 2 by the No. 1 pump 1, and the chemical milling waste liquid in the membrane separator 2 passes through the filter tube 24 distributed in the membrane under the action of pressure and enters the membrane through the membrane wall In the central tube, and discharged into the membrane filter body, so that the sodium hydroxide solvent in the waste liquid can be permeated and collected, and the concentration of the impermeable matter intercepted by the outer wall of the membrane filter tube increases gradually. When the solid concentration increases to a certain level, the membrane is filtered Stop the device, stop the No. 1 pump 1 from entering the liquid, open the No. 1 valve 101, and the No. 3 valve 103. Inject the compressed air to make the liquid pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com