Washing device and washing method for fillers of biological desulfurization tower

A technology of biological desulfurization and flushing device, applied in fuel, gas fuel, petroleum industry, etc., can solve the problems of packing layer clogging, reducing the desulfurization effect of packing layer, unable to clean the packing layer, etc., so as to improve purification efficiency, shorten cleaning time, The effect of avoiding biogas waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

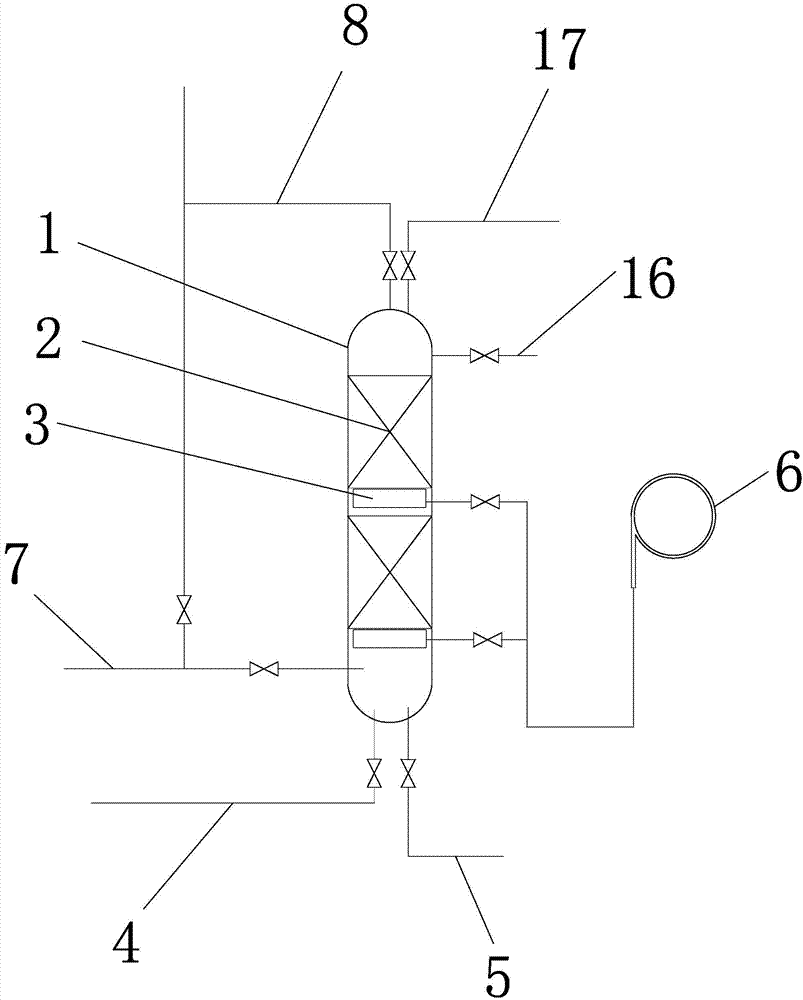

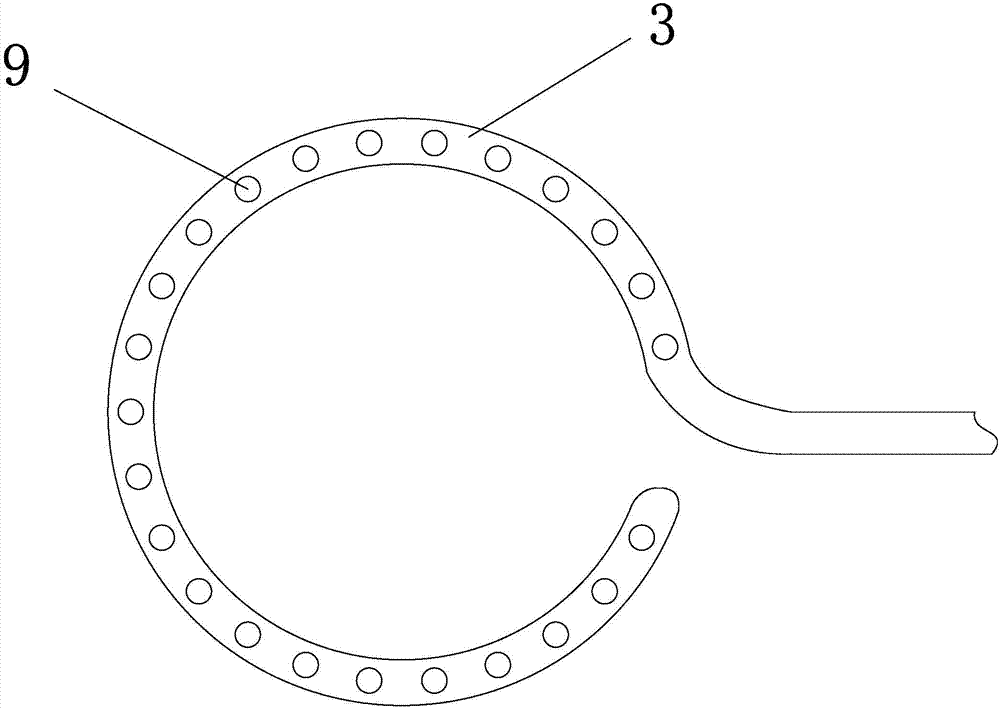

[0023] Embodiment 1: as figure 1 , 2As shown, a biological desulfurization tower packing flushing device, two packing layers 2 are longitudinally arranged inside the desulfurization tower 1, and there is a gap between the two packing layers, and the desulfurization tower 1 has a biogas inlet 7 and a biogas outlet 8, and a biogas inlet 7 It is located below the desulfurization tower 1 , and the biogas outlet 8 is located above the desulfurization tower 1 . An exhaust pipe 17 is installed on the top of the desulfurization tower 1 , a water inlet pipe 4 is installed under the desulfurization tower 1 , and a sewage discharge pipe 5 is installed at the bottom of the desulfurization tower 1 . A perforated aeration disc 3 is installed under each packing layer 2. The perforated aeration disc 3 is ring-shaped. One end of the perforated aeration disc 3 is sealed, and the other end is connected to the air source 6. The air source 6 is an air compressor. . Aeration holes 9 are arranged...

Embodiment 2

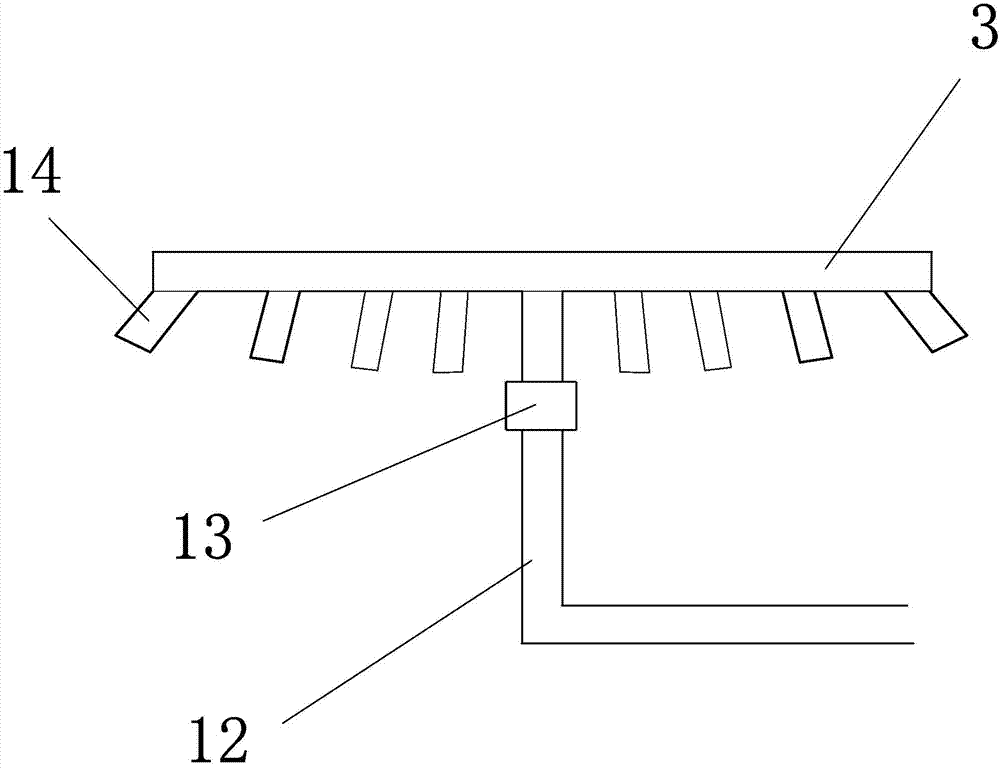

[0025] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as image 3 , 4 As shown, the perforated aeration disc includes a ring pipe 10, the gas source 6 is connected to the axis of the ring pipe 10 through a vertical axis pipe 12, and the axis of the ring pipe 10 is connected to the ring pipe through three rib pipes 11, The tendon tube 11 evenly surrounds the axis of the ring tube 10 . The axial center of the ring pipe 10 is connected with the vertical shaft pipe 12 through a pneumatic rotary joint 13 . The aeration hole 9 is located on the ring pipe 10, and the aeration hole 9 evenly surrounds the axis of the ring pipe 10. A guide sleeve 14 is installed on the aeration hole 9. The guide sleeve 14 is arranged obliquely and has an angle of 60° with the vertical plane. °. The upper surface of the perforated aeration disc 3 is attached to the lower surface of the packing layer 2 .

[0026] The gas from the g...

Embodiment 3

[0027] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that, as image 3 , 5 As mentioned above, the perforated aeration disc includes six bronchus 15, one end of the six bronchus 15 is sealed, and the other end is connected. The six bronchus 15 form a centrally symmetrical structure, and the air source passes through the vertical axis tube 12 and the symmetrical center of the bronchi. Connected, and the connection is a pneumatic rotary joint. The aeration holes are located on the same side of the bronchi, that is, they evenly surround the symmetrical center of the bronchi to form a centrosymmetric structure.

[0028] The gas from the gas source enters the symmetrical center of the six bronchi through the vertical shaft tube, fills the bronchi respectively, and then discharges from the aeration holes on the bronchi. Since the aeration holes are evenly distributed around the symmetrical center of the bronchus and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com