Dual-curing composition

A dual-curing and composition technology, applied to light-curing compositions, can solve problems such as limited methods through the field of thermal curing, and achieve the effect of high strength and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

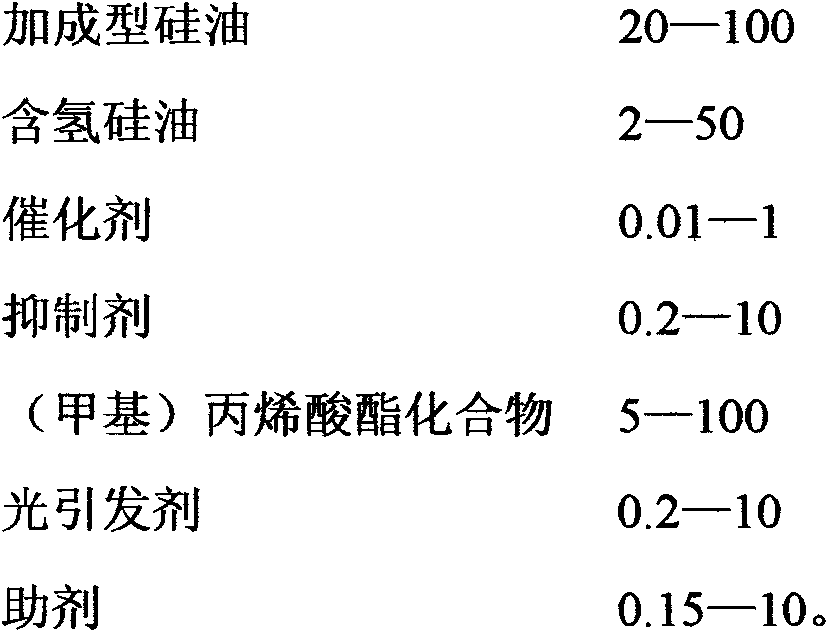

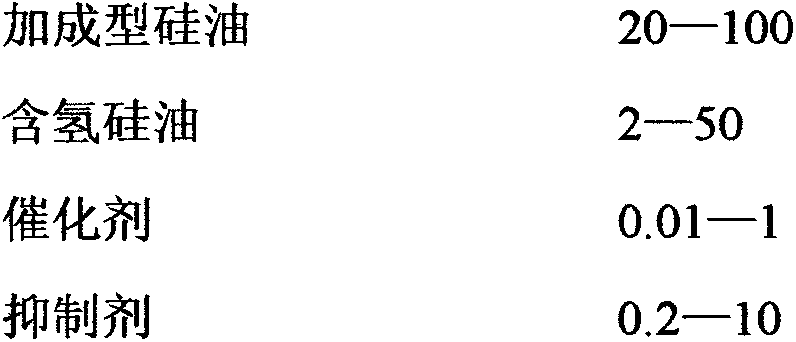

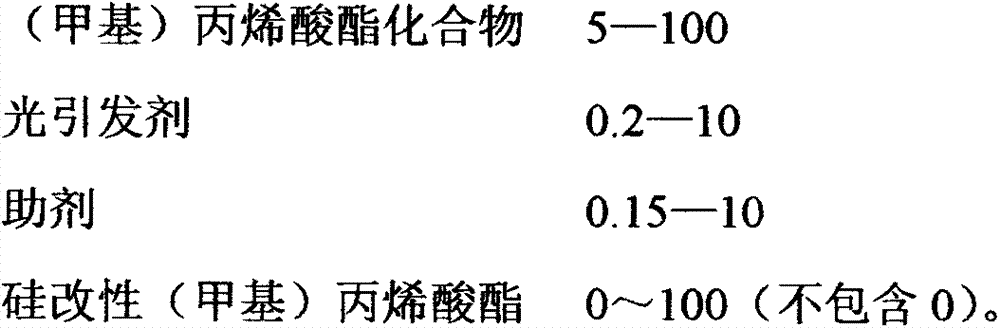

Method used

Image

Examples

Embodiment 1

[0042] The dual curing composition of this example contains: 20 parts of vinyl-terminated divinyl silicone oil with a viscosity of 10000 mPa.S, 2 parts of active hydrogen-terminated hydroxyl-terminated silicone oil, 0.2 part of benzodiazepine, 0.01 part of 2,5- Dimethyl-2,5-bis(tert-butylperoxy)hexane, 5 parts of DPHA, 0.2 parts of 184, 0.15 parts of fluorosilicone defoamer.

[0043] The composition was heated and cured at 160° C. for 15 minutes, and then UV cured to obtain a dual-cured material, which had a rubber texture.

Embodiment 2

[0045] The dual curing composition of this embodiment comprises: 60 parts of vinyl-terminated divinyl silicone oil with a viscosity of 10000 mPa.S, 20 parts of active hydrogen-terminated hydroxyl-terminated silicone oil, 2 parts of ethynyl cyclohexanol, and 0.2 parts of chloroplatinic acid solution , 30 parts of 6145 (acrylate resin), 30 parts of DPHA, 7 parts of 184, 4 parts of fluorosilicone defoamer.

[0046] The composition was heat-cured at 160° C. for 15 minutes, and then UV-cured to obtain a dual-cure material.

Embodiment 3

[0048] The dual curing composition of this embodiment comprises: 10 parts of vinyl-terminated divinyl silicone oil with a viscosity of 850 mPa.S, 20 parts of vinyl-terminated divinyl silicone oil with a viscosity of 1000 mPa.S, 60 parts of vinyl-terminated divinyl silicone oil with a viscosity of 10000 mPa.S Vinyl-terminated divinyl silicone oil, 10 parts of vinyl-terminated divinyl silicone oil with a viscosity of 5,000,000mPa.S, 20 parts of active hydrogen-terminated hydroxyl-terminated silicone oil, 30 parts of active hydrogen-terminated and side chains also containing active hydrogen Hydrogen-containing silicone oil, 4 parts of diallyl maleate, 6 parts of ethynyl cyclohexanol, 0.6 parts of chloroplatinic acid solution, 0.4 parts of platinum-vinyl siloxane, 90 parts of CN2302 (acrylate resin), 10 parts Parts of methyl methacrylate, 7 parts of 184, 3 parts of TPO, 4.4 parts of fluorine-containing defoamer, 5 parts of fluorosilicon defoamer, 0.1 part of polymerization inhibito...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com