Method for sintering manganese zinc ferrite magnetic material in combination of microwave and electric heating

A technology of manganese-zinc ferrite and magnetic materials, which is applied in the field of microwave electric heating combined sintered manganese-zinc ferrite magnetic materials, can solve the problems of high production cost, uneven heating, product cracking, etc., and achieve shortened drainage Glue time, shorten heating time, and ensure the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

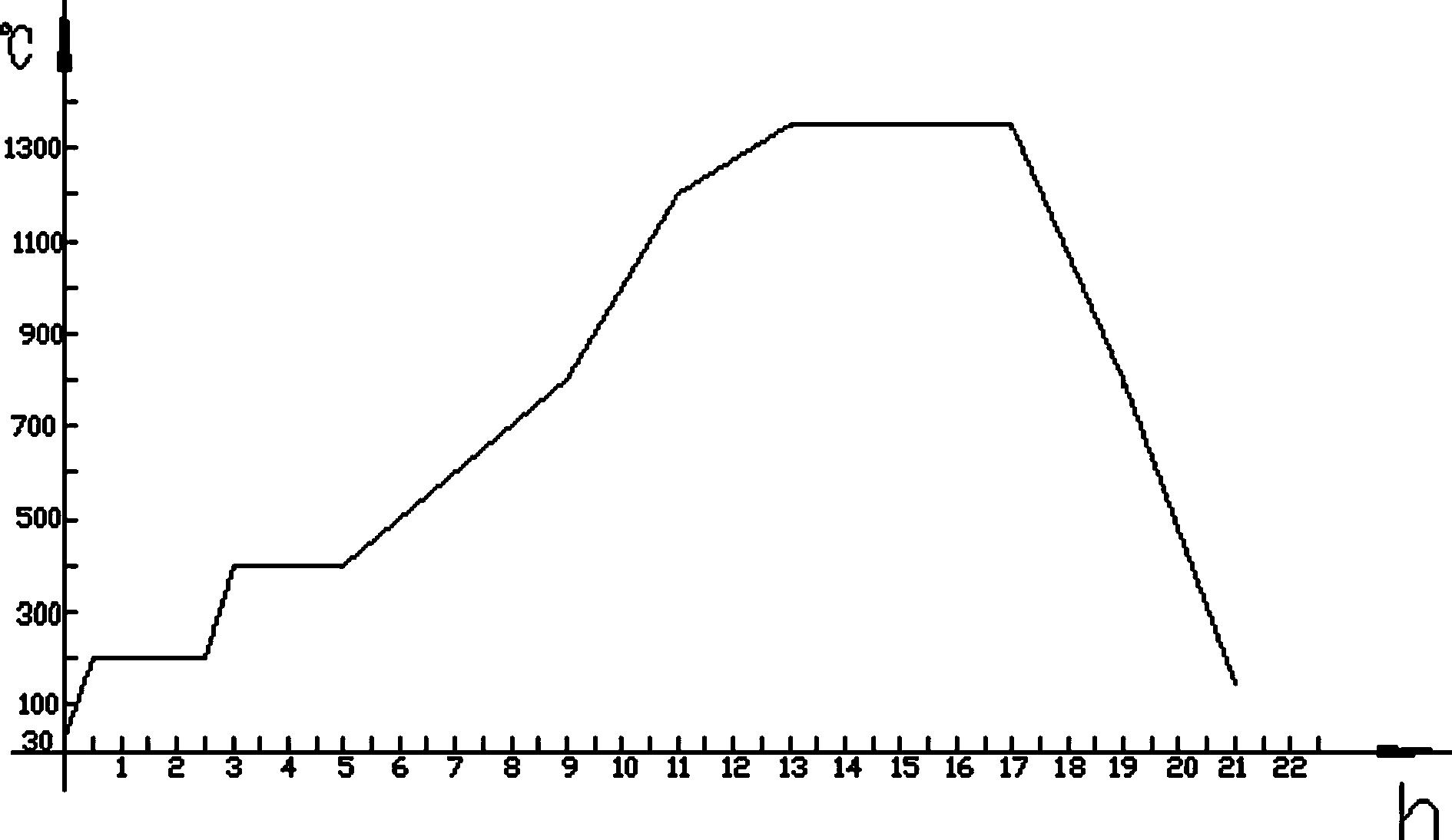

[0016] Depend on figure 1 As shown, the method of sintering manganese-zinc-ferrite magnetic materials by microwave electric heating combination is as follows: firstly, use microwave heating method for 0.4 hours to raise the temperature from room temperature to 180 ℃, and then keep the temperature for 1.8 hours. No pressure, pump air to realize the drainage process of the substance; then use microwave heating method to raise the temperature to 380°C for 0.4 hours, and then keep the temperature for 1.8 hours, there is no pressure in the furnace during this process, pump air to realize the drainage and debinding of the substance process; then use the traditional silicon carbon rod heating method to raise the temperature to 780°C in 3.8 hours, the oxygen content in the furnace is controlled at 1800PPM during this process, and then use the traditional silicon molybdenum rod heating method to raise the temperature to 1180°C in 1.8 hours. In this process, the oxygen content in the fu...

Embodiment 2

[0018] Depend on figure 1 As shown, the method of sintering manganese-zinc-ferrite magnetic materials by microwave electric heating combination is as follows: firstly, use microwave heating method to raise the temperature from room temperature to 210°C for 0.6 hours, and then keep the temperature for 2.1 hours. No pressure, pump air to realize the drainage process of the substance; then use microwave heating method to raise the temperature to 410°C for 0.6 hours, and then keep the temperature for 2.1 hours, there is no pressure in the furnace during this process, pump air to realize the drainage and debinding of the substance process; then use the traditional silicon carbon rod heating method to raise the temperature to 810°C in 4.2 hours, the oxygen content in the furnace is controlled at 2200PPM during this process, and then use the traditional silicon molybdenum rod heating method to raise the temperature to 1210°C in 2.1 hours. In this process, the oxygen content in the fu...

Embodiment 3

[0020] Depend on figure 1 As shown, the method of sintering manganese-zinc-ferrite magnetic materials by microwave electric heating combined method is as follows: firstly, use microwave heating method for 0.5 hours to raise the temperature from room temperature to 200°C, and then keep the temperature for 2 hours. No pressure, pump air to realize the drainage process of the substance; then use microwave heating for 0.5 hours to raise the temperature to 400°C, and then keep the temperature for 2 hours, there is no pressure in the furnace during this process, pump air to realize the drainage and debinding of the substance process; then use the traditional silicon carbide rod heating method to raise the temperature to 800°C for 4 hours, the oxygen content in the furnace is controlled at 2000PPM during this process, and then use the traditional silicon molybdenum rod heating method to raise the temperature to 1200°C for 2 hours. In this process, the oxygen content in the furnace is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com