Method for machining megawatt wind turbine blade mould

A wind power blade and megawatt-level technology, which is applied in the field of processing megawatt-level wind power blade molds, can solve the problems of high CNC machining cost, unfavorable project development, and long production and processing cycle, so as to improve production efficiency, shorten production cycle, and save space. use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific examples of the present invention are as follows.

[0047] Firstly, a laser tracker is introduced to accurately test the molding line during the entire mold making to ensure the processing quality.

[0048] Secondly, use 3D software to design the structure of the entire mold, including flanges, steel frames, layers, heating layers, surface layers, etc., and formulate the manufacturing process.

[0049] The main steps of the preparation method are:

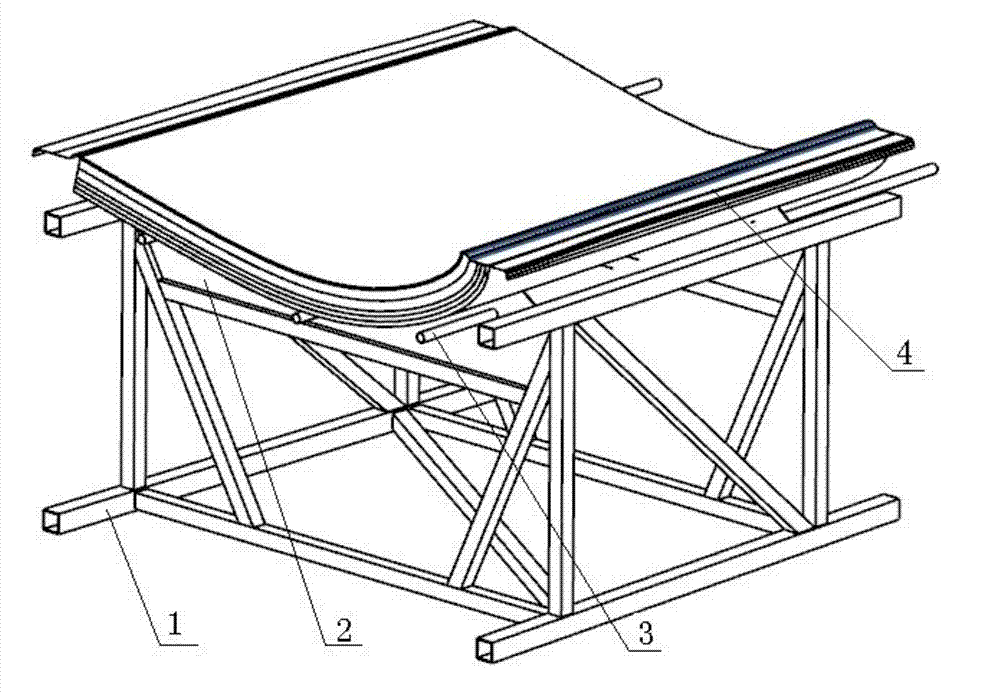

[0050] 1. Make a steel frame, install profiled steel plates every 2m on the steel frame, and distribute round steel in the middle of the profiled steel plates. Use laser tracker to detect and adjust the size and position of each place, such as figure 1 shown.

[0051] 2. Lay the smooth-surfaced skin laminates on the steel frame, connect them to the steel frame with self-tapping screws, and use the laser tracker to detect to ensure that the molded line of each place meets the design requirements.

[0052] 3. Lay a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com