Method for preparing hypotensive mulberry leaf tea bag

A technology of making tea in bags and lowering blood pressure, which is applied in the field of food industry and achieves the effect of wide sources and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

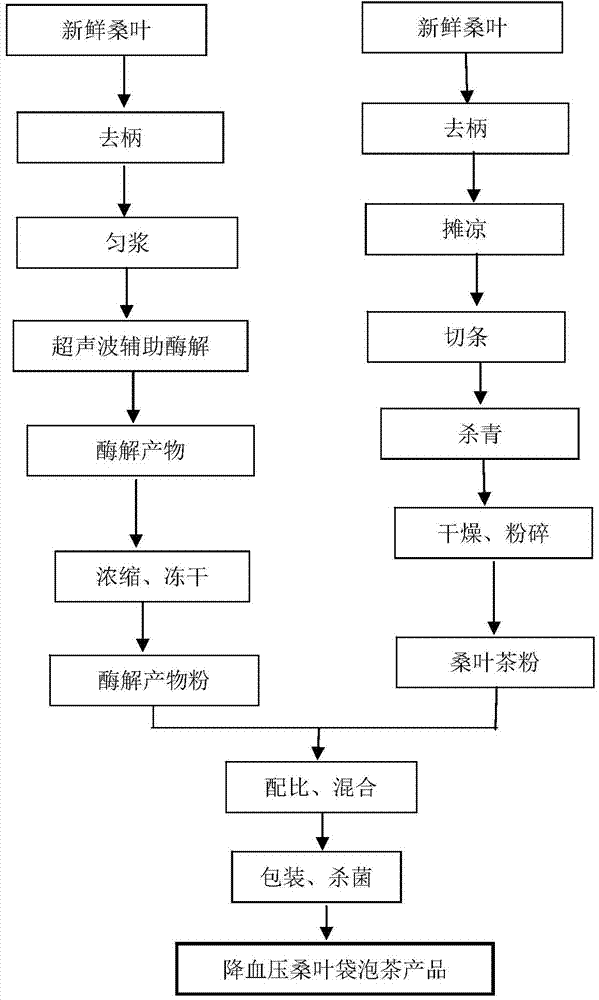

Image

Examples

Embodiment 1

[0022] Remove the stalks of fresh mulberry leaves and clean them. After beating, make a 5% (w / v, g / mL) suspension with distilled water, place in a 40kHz ultrasonic washing tank, set the temperature of the water bath to 40°C, etc. When the temperature of the water bath reaches the set temperature, at natural pH, add neutral protease (sourced from Bacillus subtilis) according to the enzyme amount of 2500U / g, stir evenly and turn on the ultrasonic wave, the ultrasonic power is 90W, ultrasonic assisted enzymatic hydrolysis for 30 minutes, and then centrifuged. The enzymatic hydrolyzate was concentrated, freeze-dried, and set aside; fresh mulberry leaves were removed, cooled at room temperature for 5 hours, cut into 1 cm wide strips, boiled for 60 seconds, then dried in the shade at room temperature for 10 hours, dried at 50°C, and crushed. For mulberry leaf tea powder, add 1% (w / w, g / g) of the above-mentioned freeze-dried mulberry leaf protein enzymatic hydrolyzate to the mulberry ...

Embodiment 2

[0024] Remove the stalks of fresh mulberry leaves and clean them. After beating, make a 7.5% (w / v, g / mL) suspension with distilled water, place it in a 40kHz ultrasonic washing tank, set the temperature of the water bath to 45°C, etc. When the temperature of the water bath reaches the set temperature, under the natural pH, add neutral protease (sourced from Bacillus subtilis) according to the enzyme amount of 3000U / g, stir evenly and turn on the ultrasonic wave, the ultrasonic power is 105W, ultrasonic assisted enzymatic hydrolysis for 40min, and then centrifuged. The enzymatic hydrolyzate was concentrated, freeze-dried, and set aside; another fresh mulberry leaf was removed, cooled at room temperature for 6 hours, cut into 2cm wide strips, boiled for 75 seconds, then dried in the shade at room temperature for 11 hours, dried at 55°C, and crushed. For mulberry leaf tea powder, add 3% (w / w, g / g) of the above-mentioned freeze-dried mulberry leaf protein enzymatic hydrolyzate to t...

Embodiment 3

[0026] Remove the stalks of fresh mulberry leaves and clean them. After beating, make a 10% (w / v, g / mL) suspension with distilled water, place it in a 40kHz ultrasonic washing tank, set the temperature of the water bath to 50°C, etc. When the temperature of the water bath reaches the set temperature, under the natural pH, add neutral protease (sourced from Bacillus subtilis) according to the enzyme amount of 3500U / g, stir evenly and turn on the ultrasonic wave, the ultrasonic power is 120W, ultrasonic assisted enzymatic hydrolysis for 50min, and then centrifuged. The enzymatic hydrolyzate was concentrated, freeze-dried, and set aside; fresh mulberry leaves were removed, cooled at room temperature for 7 hours, cut into 3 cm wide strips, boiled for 90 seconds, then dried in the shade at room temperature for 12 hours, dried at 60°C, and crushed. For mulberry leaf tea powder, add 5% (w / w, g / g) of the above-mentioned freeze-dried mulberry leaf protein enzymatic hydrolyzate to the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com