Device for filling tank of motor vehicle

A technology for motor vehicles and storage tanks, which is applied in the directions of mechanical equipment, machines/engines, and the arrangement of fuel supply combined with internal combustion engines, etc., can solve problems such as being unsuitable for fast filling of storage tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

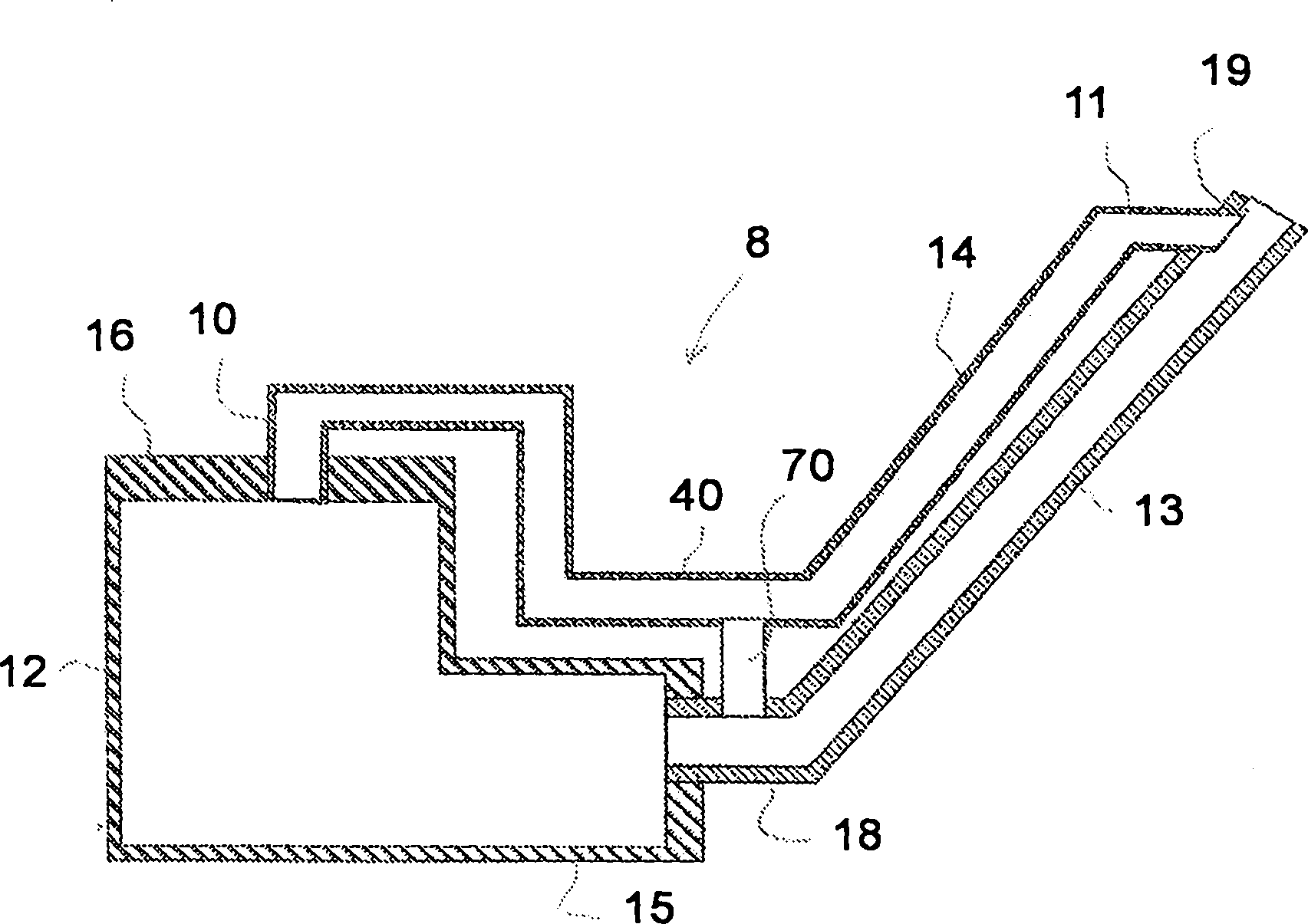

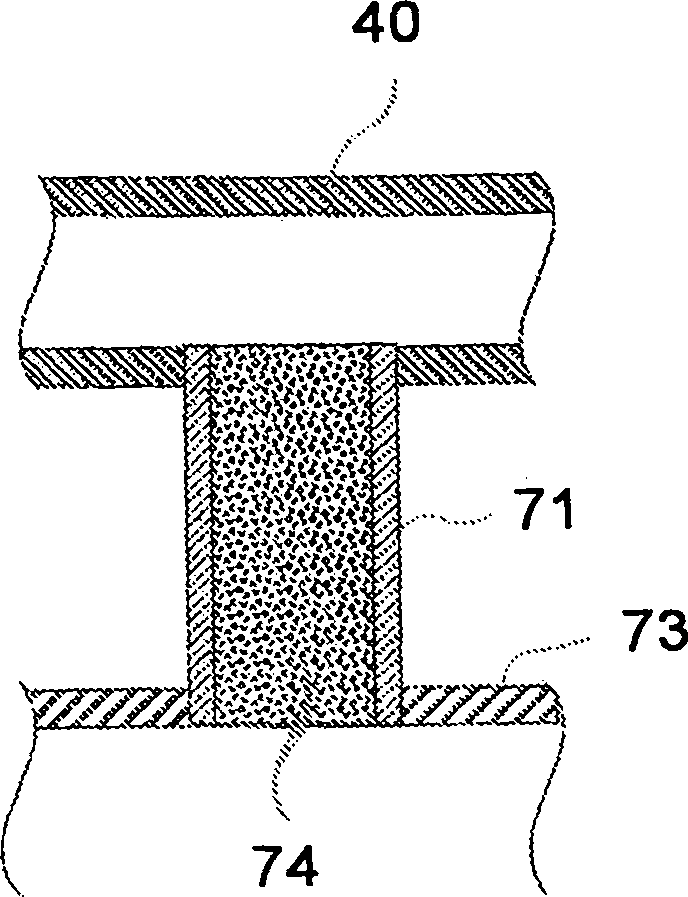

[0020] figure 1 and figure 2 Devices 7 and 8 are shown for filling a tank 12 for supplying liquid to components (not shown) of the motor vehicle. The component of the motor vehicle is in particular an exhaust system converter.

[0021] figure 1 and figure 2 The devices in are used in particular for selective catalytic reduction exhaust system converters (often abbreviated as "SCR" converters by the English acronym).

[0022] Tank 12 contains a reducing agent that reduces nitrogen oxides NOx emitted by the vehicle's internal combustion engine (not shown). The reducing agent is, for example, a liquid containing 30-35% diluted urea in demineralized water. A dose of liquid is normally taken from tank 12 for delivery from a transfer conduit to an injector mounted on the converter of the exhaust system. The injected dose of liquid (NH2-CO-NH2) allows to substantially convert the predetermined amount of nitrogen monoxide and nitrogen dioxide emitted by the engine into water (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com