Separate type pressure-bearing anti-corrosion device

An anti-corrosion device and separate technology, applied in the direction of pressure vessels, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc., can solve problems such as safety accidents, achieve the goal of eliminating safety accidents, high safety, and high cost solutions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

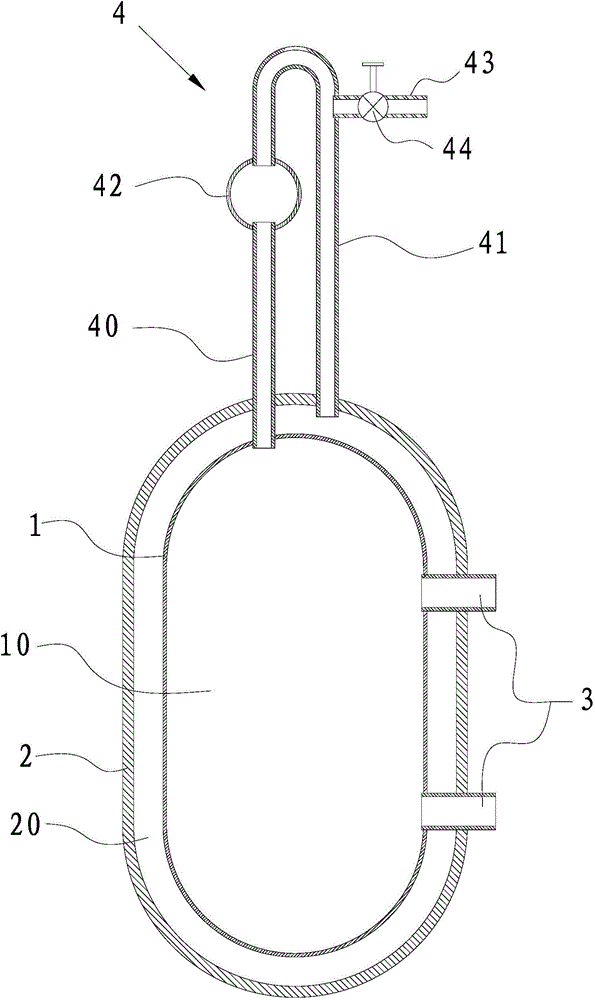

[0019] Such as figure 1 As shown, the separated pressure-bearing anti-corrosion device provided in this example includes a corrosion-resistant material layer 1 with an area 10 containing a corrosive pressure medium inside, which is arranged on the outer periphery of the corrosion-resistant material layer 1 and formed between the corrosion-resistant material layer 1 The pressure-bearing material layer 2 of the separation area 20 is used to feed and discharge the inlet and outlet 3 of the corrosive pressure medium into the area 10 containing the corrosive pressure medium, and is used to balance the area 10 containing the corrosive pressure medium and the separation area. 20 Pressure balance system for internal medium pressure 4.

[0020] Further, the corrosion-resistant material layer 1 is made of materials with good corrosion resistance; the pressure-bearing material layer 2 is made of high-strength materials; the inlet and outlet 3 pass through the separation area 20 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com