Waste leather superfine fiber and its high electromagnetic shielding material composited with polyvinyl alcohol and their preparation method

A superfine fiber, polyvinyl alcohol technology, applied in chemical instruments and methods, magnetic field/electric field shielding, fiber processing, etc., can solve the problems of high degree of protein fiber bundles, composite modification, inability to melt, etc., to achieve adaptability Excellent, good flexibility, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

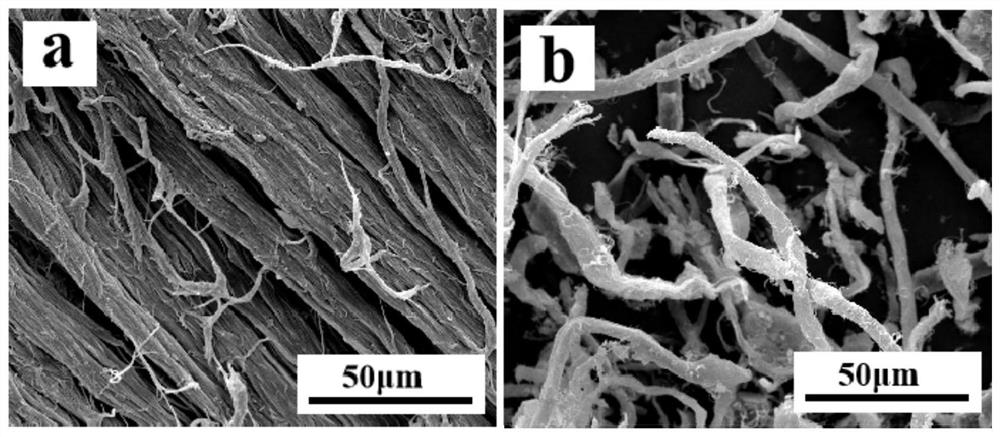

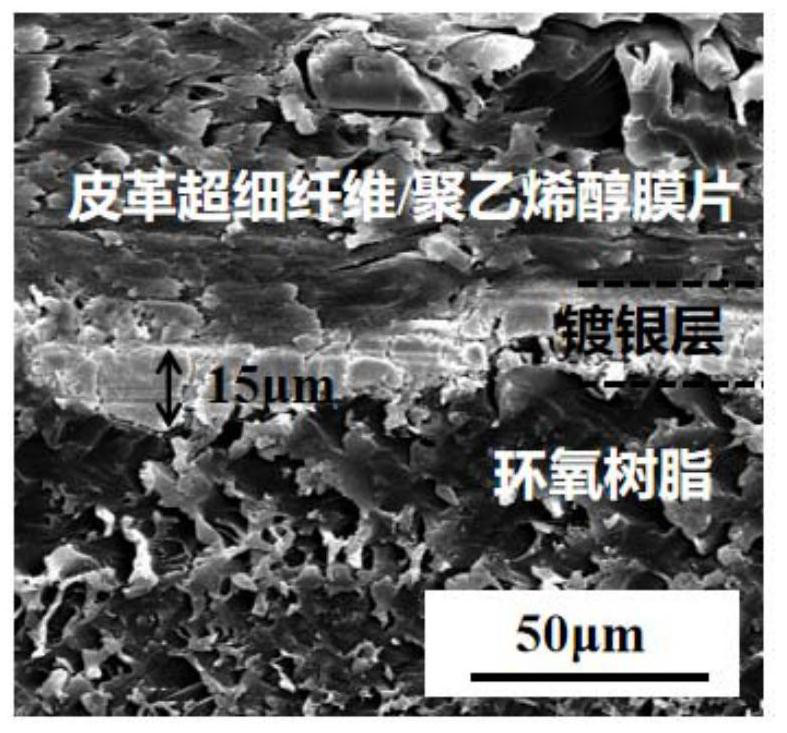

[0039] 1) Put the tanning solid waste into the disc-shaped mechanochemical reactor, and feed circulating cooling water at the same time, control the temperature of the disc surface to 35°C, control the pressure to 20kN, control the speed to 400 rpm, control vacuum feeding, and circulate grinding 9 times to get waste leather microfibers, the average fiber diameter of the ultrafine fibers is 2 μm, and the average length is 100 μm;

[0040] 2) 100 parts of polyvinyl alcohol 1799 (that is, the degree of polymerization is 1700, and the degree of alcoholysis is 99%) is heated and dissolved in hot water at 95 ° C to obtain a polyvinyl alcohol solution with a concentration of 20 wt%, and then mixed with 5 parts of glycerin and 200 parts Mix waste leather microfibers, then drop 0.3wt% polyvinyl alcohol defoamer BK-802 into the mixed suspension, and use a high-speed stirrer to mix and stir for 20 minutes;

[0041] 3) Put the obtained mixed liquid into an ultrasonic device with a power o...

Embodiment 2

[0046] 1) Put the tanning solid waste into the disc-shaped mechanochemical reactor, and feed circulating cooling water at the same time, control the temperature of the disc surface to 20°C, control the pressure to 17kN, control the speed to 300 rpm, control the vacuum feeding, and circulate the grinding 8 times to get the waste leather superfine fiber, the average fiber diameter of the superfine fiber is 5 μm, and the average length is 500 μm;

[0047] 2) Heat and dissolve 100 parts of polyvinyl alcohol 2597 in hot water at 80°C to obtain a polyvinyl alcohol solution with a concentration of 10 wt%, then mix it with 10 parts of urea and 400 parts of waste leather microfiber, and then mix it in the mixed suspension Add 0.1wt% polyvinyl alcohol defoamer DF-898 dropwise, and use a high-speed stirrer to mix and stir for 10 minutes;

[0048] 3) Put the obtained mixed liquid into an ultrasonic device with a power of 800W for 10 minutes at room temperature, and then stir and defoam at...

Embodiment 3

[0053] 1) Put the tanning solid waste into the disc-shaped mechanochemical reactor, and feed circulating cooling water at the same time, control the temperature of the disc surface to 5°C, control the pressure to 15kN, control the speed to 100 rpm, control the vacuum feeding, and circulate the grinding 7 times to get the waste leather superfine fiber, the average fiber diameter of the superfine fiber is 8 μm, and the average length is 800 μm;

[0054] 2) Heat and dissolve 100 parts of polyvinyl alcohol 1799 in hot water at 90°C to obtain a polyvinyl alcohol solution with a concentration of 10 wt%, then mix it with 10 parts of caprolactam and 200 parts of waste leather microfiber, and then mix it in the mixed suspension Add 0.1wt% polyvinyl alcohol defoamer GPE-3000 dropwise, and mix with a high-speed stirrer for 10 minutes;

[0055] 3) Put the obtained mixed liquid into an ultrasonic device with a power of 700W at room temperature for ultrasonic treatment for 20 minutes, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com