Electronic grade glass fiber cloth surface treating agent and method

A technology of glass fiber cloth and surface treatment agent, which is applied in the field of electronic grade glass fiber cloth surface treatment agent and electronic grade glass fiber cloth. Infiltrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

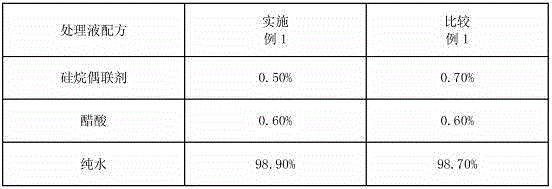

[0034] Table 1-1 Formula table of silane coupling agent treatment agent (each component by mass percentage)

[0035]

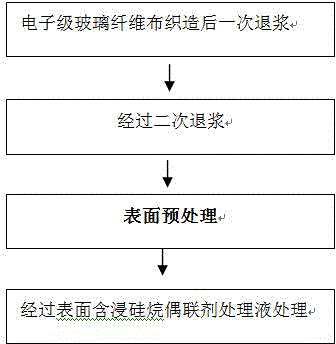

[0036] Table 1-1 Use the 1506 desizing cloth produced by our company (with a thickness of 0.14mm±0.24 and above), and use the treatment agent formula in Table 1-1 for treatment. The specific production process is as follows figure 1 shown. Embodiment 1 uses the pretreatment process of 0.10% silane coupling agent and 0.10% acetic acid and the balance is pure water for spraying. Comparative Example 1 did not carry out the pretreatment process.

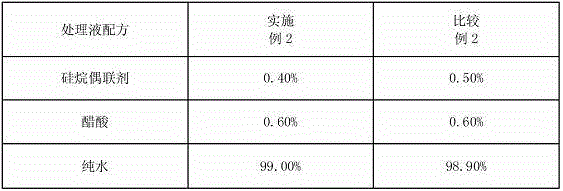

[0037] Table 1-2 Formula table of silane coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com