Polylactic acid/clay nanocomposite material and its preparation method and method for preparing foamed products

A technology of nano-composite materials and foamed products, applied in the field of foamed products, can solve the problems of low cost of foamed materials, dissipation of foaming agents, and difficulty in obtaining them, and achieves improved melt strength, increased cell density, The effect of increasing the foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Put 1 part of nano-montmorillonite into 50 parts of distilled water, raise the temperature to 50°C and stir for 30 minutes, adjust the pH value of the mixed solution to 4.0 with 0.2mol / mL hydrochloric acid to form a mixed solution; add 0.02 parts to the mixed solution Cationic surfactant (hexadecyltrimethylammonium bromide), stirred at 50°C for 5 hours. After natural cooling to room temperature of 25°C, organically modified nanoclay was obtained by centrifugal separation, washing, drying and grinding;

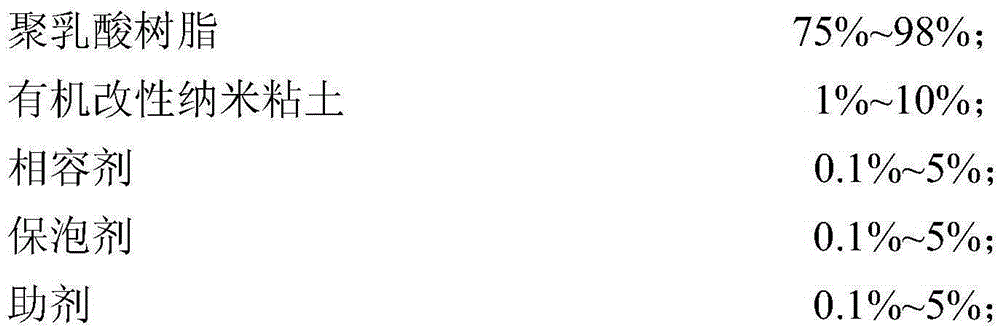

[0051] (2) 94 parts of polylactic acid resin (Ingeo2002D, melt index 3.0g / 10min, weight average molecular weight of 187,000), 2 parts of organically modified nanoclay prepared in step (1), 1 part of compatibilizer (organosiloxane Alkane coupling agent KH-550), 2 parts of foam-preserving agent (glyceryl monostearate) and 1 part of antioxidant (hindered phenolic antioxidant 1076) are mixed, and mixed by a screw extruder to obtain Granular polylactic acid / clay nanocomp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com