BOPET (biaxially oriented polyester film) for TTR (thermal transfer ribbon) resin base

A resin-based, base material technology, applied in the field of BOPET (biaxially oriented polyester film, can solve the problems of inability to meet thermal stability, peeling crystallinity coating solvent surface adaptability, etc., to meet performance requirements, surface adaptability, etc. Sexual improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

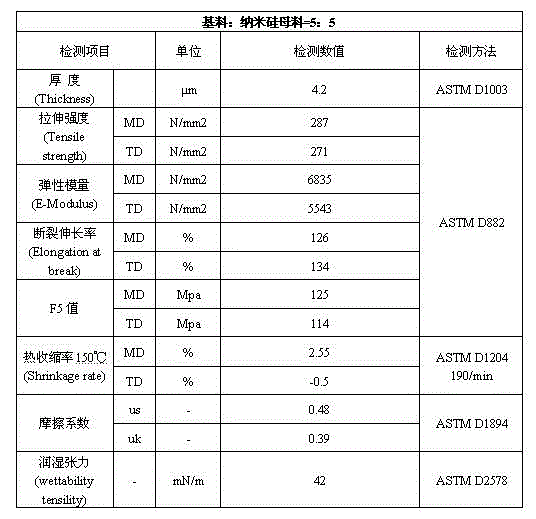

[0014] Prepare by base material and organosilicon masterbatch=3.5:6.5 mass ratio, described base material is PET, i.e. polyethylene terephthalate; Described organosilicon masterbatch is dimethyl dichlorosilane ( CH 3 ) 2 SiC l2 Mixture with polyethylene terephthalate, in which the content of dimethyldichlorosilane is 7000ppm.

[0015] After the prepared raw materials are mixed and dried, they enter the extruder to melt the raw materials at a temperature of 280 ° C. First, the melted raw materials are filtered through a 5 μm high-precision filter, extruded through a T-shaped die, and cooled on a quenching roller. , after preheating with MDO at 55°C~76°C, 3.65 times longitudinal drawing and 4.1 times TDO transverse drawing are carried out, cooling and crystallization treatment is carried out at the end of TDO transverse drawing, and then semi-finished products are harvested through trimming, winding and other processes , and finally after cutting and packaging, it becomes a 4...

Embodiment 2

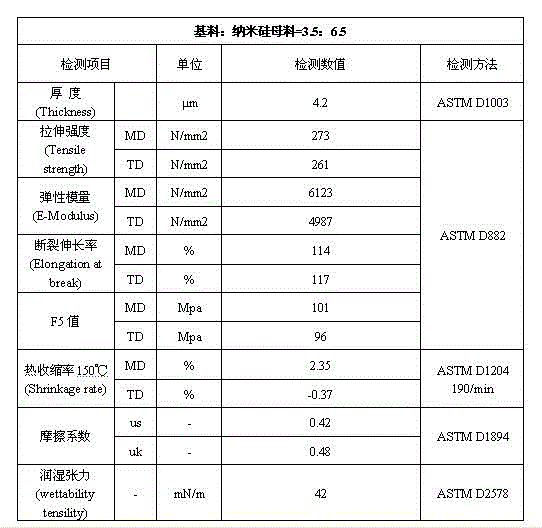

[0020] The preparation method is the same as in Example 1, only adjusting the base material and the nano-silicon master batch to prepare by a mass ratio of 4:6, the base material being PET, i.e. polyethylene terephthalate; the organosilicon master batch Dimethyldichlorosilane (CH 3 ) 2 SiC l2 Mixture with polyethylene terephthalate, in which the content of dimethyldichlorosilane is 7000ppm.

[0021] Slitting the BOPET finished product prepared in this example, the excellent-grade rate of the finished product can reach 91%, and the rate of coated A-grade product can reach 83%.

[0022] The main physical and chemical indicators of the TTR resin-based high-speed coating special-purpose 4.2 micron BOPET finished product measured in this embodiment are shown in the following table:

[0023]

Embodiment 3

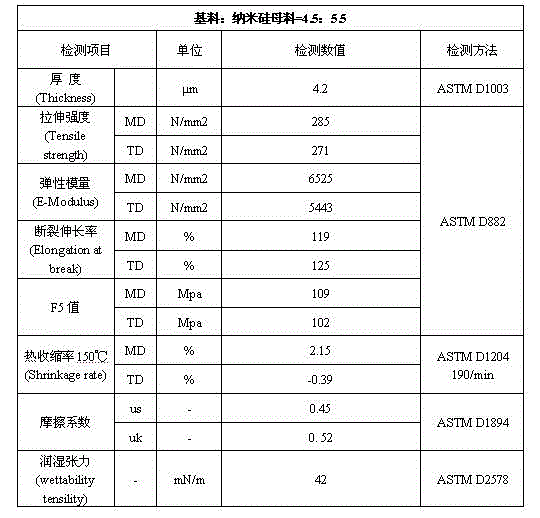

[0025] The preparation method is the same as in Example 1, only adjusting the base material and the nano-silicon master batch to prepare by the mass ratio of 4.5:5.5, the base material is PET, i.e. polyethylene terephthalate; the silicone master batch Dimethyldichlorosilane (CH 3 ) 2 SiC l2 Mixture with polyethylene terephthalate, in which the content of dimethyldichlorosilane is 7000ppm.

[0026] Slitting the BOPET finished product prepared in this example, the rate of high-grade finished product can reach 90%, and the rate of coated A-grade product can reach 87%.

[0027] The main physical and chemical indicators of the TTR resin-based high-speed coating special-purpose 4.2 micron BOPET finished product measured in this embodiment are shown in the following table:

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com