Heat treatment method after magnesia carbon brick recovery

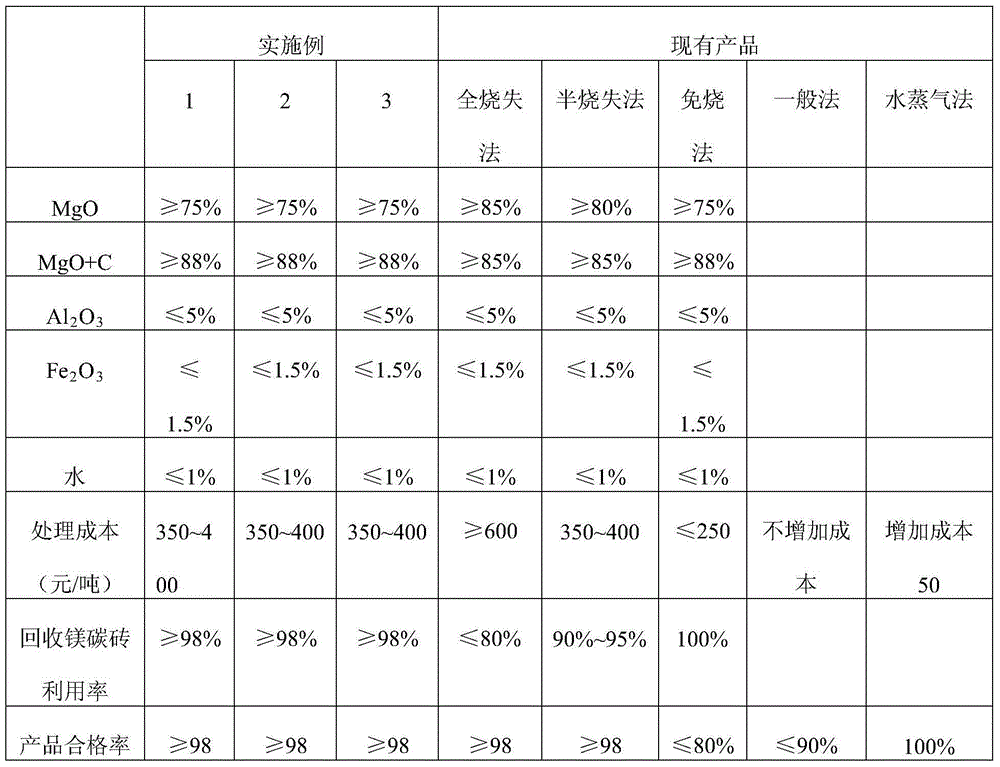

A heat treatment method and technology of magnesia-carbon bricks, which are applied in the field of heat treatment of recycled refractory materials after use, can solve the problems of complicated process and increased processing costs of recycled magnesia-carbon bricks, so as to reduce oxidation loss, reduce water vapor treatment process, and reduce treatment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A heat treatment method after recovery of magnesia carbon bricks, comprising the following steps:

[0035] 1) Select magnesia carbon bricks, remove miscellaneous bricks, and then remove impurities such as attachments and metamorphic layers on the bricks one by one;

[0036] 2) Sprinkle the magnesia carbon bricks collected in step 1);

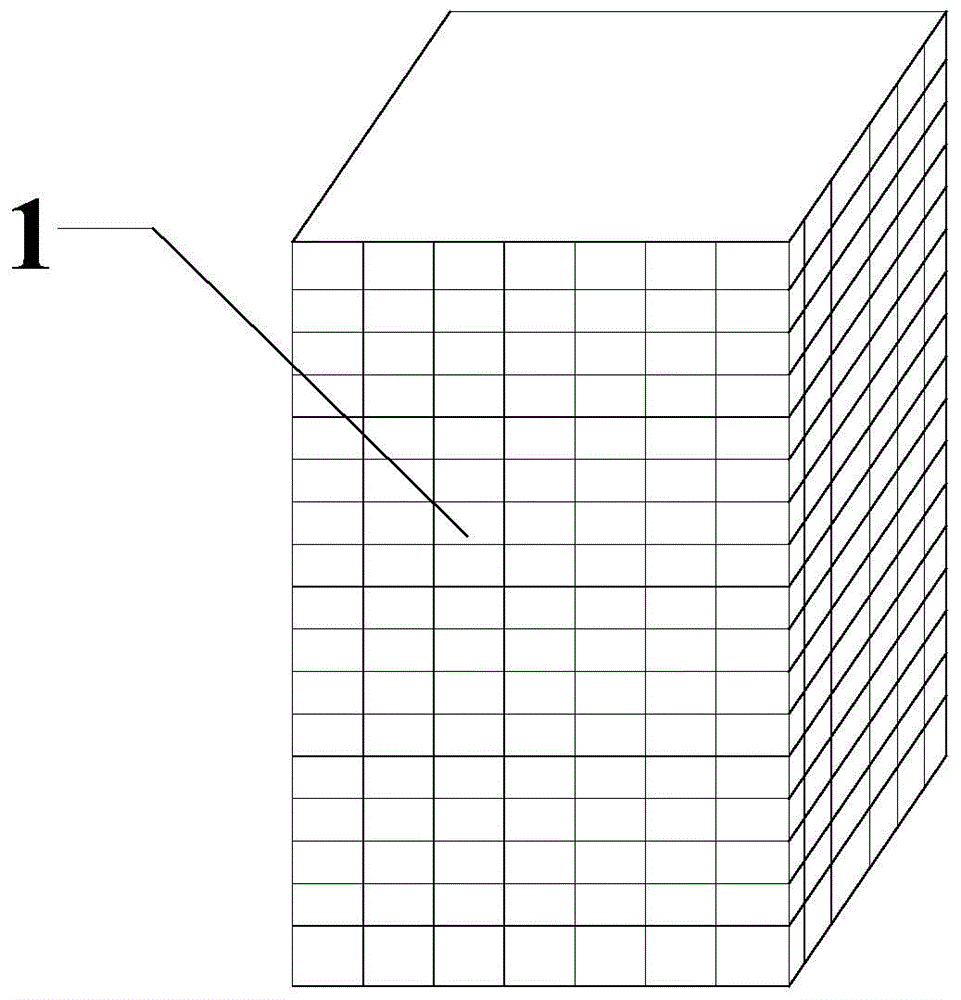

[0037] 3) Put the water-sprayed magnesia-carbon brick in a semi-closed device, put it into an electric cellar, and heat it from room temperature to 500 °C at a rate of 10 °C / min for heat preservation and heat treatment for 24 hours; among them, the semi-closed device The surrounding area and the lower end are closed, and the upper end is open. The semi-airtight device includes an inner iron basket 1 hollowed out all around and an outer shell 2 closed all around. m×2.2m×2.2m.

[0038] 4) The magnesia-carbon bricks after heat treatment in step 3) are crushed and iron-removed to obtain magnesia carbon powder. The magnesia carbon powder is ...

Embodiment 2

[0040] A heat treatment method after recovery of magnesia carbon bricks, comprising the following steps:

[0041] 1) Select magnesia carbon bricks, remove miscellaneous bricks, and then remove impurities such as attachments and metamorphic layers on the bricks one by one;

[0042] 2) Sprinkle the magnesia carbon bricks collected in step 1);

[0043] 3) Put the water-sprayed magnesia-carbon bricks in a semi-closed device, put them into an electric cellar, and heat them from room temperature to 650 °C at a rate of 5 °C / min for heat preservation and heat treatment for 12 hours; among them, the semi-closed device The surrounding and the lower end are closed, and the upper end is open. The semi-closed device includes an inner iron basket 1 hollowed out all around and an outer shell 2 closed all around. The length, width and height of the inner iron basket are 1.1m×1.1m×1.1m, and the length, width and height of the outer shell are 1.2m×1.2m×1.2m.

[0044] 4) The magnesia-carbon br...

Embodiment 3

[0046] A heat treatment method after recovery of magnesia carbon bricks, comprising the following steps:

[0047] 1) Select magnesia carbon bricks, remove miscellaneous bricks, and then remove impurities such as attachments and metamorphic layers on the bricks one by one;

[0048] 2) Sprinkle the magnesia carbon bricks collected in step 1);

[0049]3) Put the water-sprayed magnesia-carbon bricks in a semi-closed device, put them into an electric cellar, and heat them from room temperature to 800 °C at a rate of 20 °C / min for heat preservation and heat treatment for 6 hours; among them, the semi-closed device The surrounding and the lower end are closed, and the upper end is open. The semi-closed device includes an inner iron basket 1 hollowed out all around and an outer shell 2 closed all around. The length, width and height of the inner iron basket are 1.5m×1.5m×1.5m, and the length, width and height of the outer shell are 1.7m×1.7m×1.7m.

[0050] 4) The magnesia-carbon bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com