Process system for removing ammonia nitrogen/alga in surface water by enhancing conventional treatment

A conventional treatment and process system technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high operating costs, reduced water quality safety, and high construction and operating costs , to achieve the effect of high removal efficiency, low implementation difficulty and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

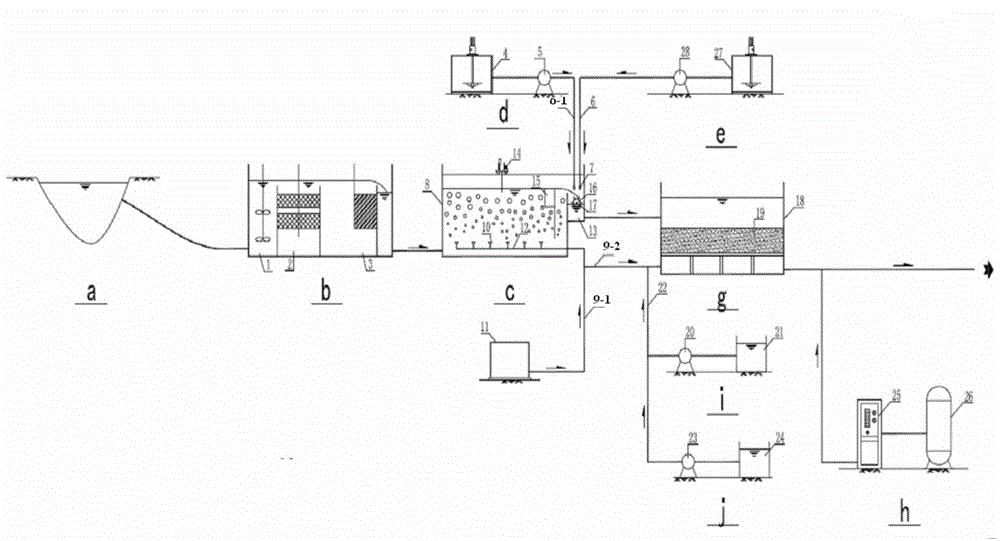

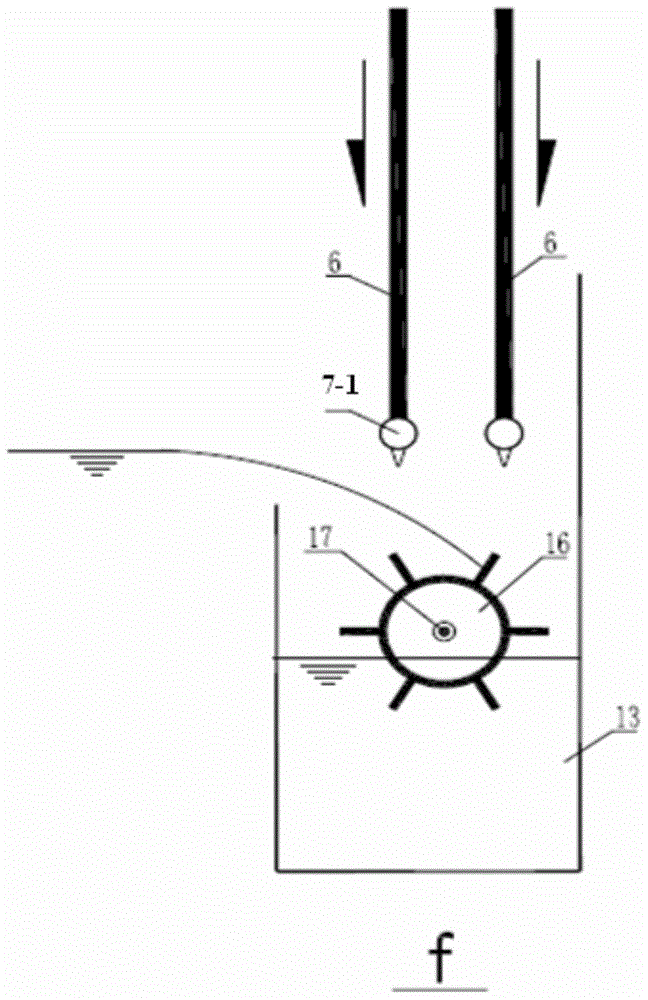

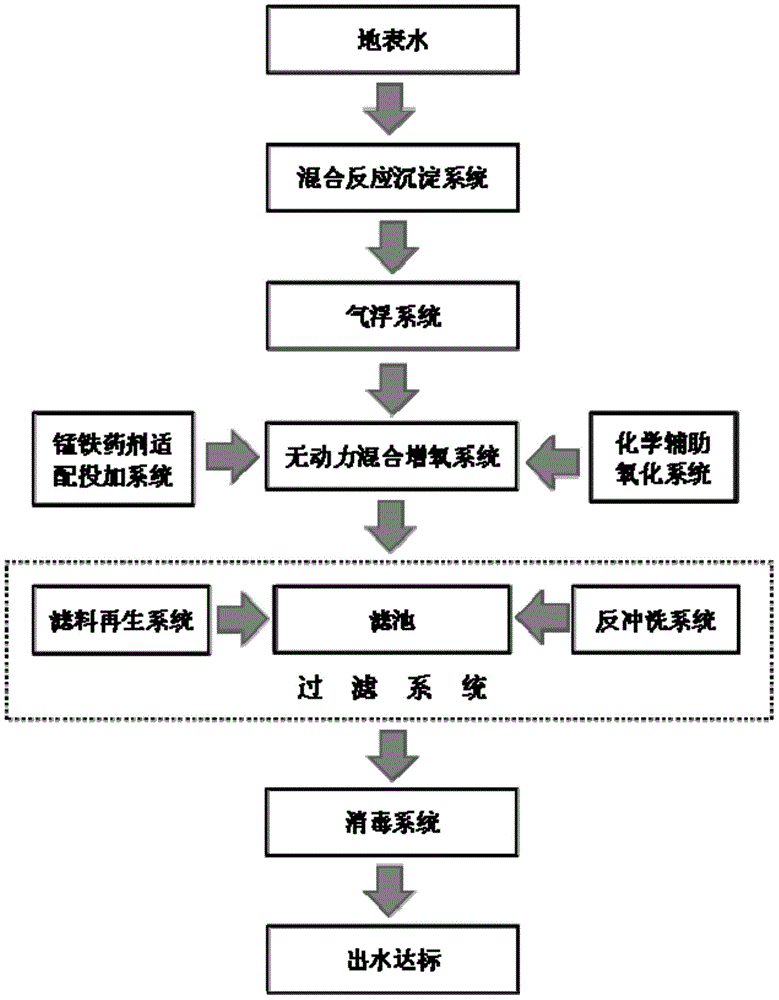

[0030]The technical idea of the present invention to solve the problem is: after the surface water is mixed, reacted, and precipitated by the mixed reaction sedimentation system, the air flotation system is used to remove the algae in the water body, and the dissolved algae in the water body is improved through the microbubble mass transfer and oxygenation. Oxygen concentration; then use the ferromanganese agent adaptation dosing system to add a certain amount of ferromanganese adapter agent to the water body, and quickly chemically oxidize the artificially adapted low-valence ferromanganese through the chemical assisted oxidation system, so that The formed oxides can be attached to the surface of the filter material to form an active filter membrane on the surface of the filter material; the unpowered mixing and aeration system fully mixes the effluent from the air flotation system with ferromanganese adapter agents and chemical oxidants, and further degrades the water body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com