Emodin solid dispersion, drug-containing pellet core, colonic targeted micropill, and applications of three

A technology of solid dispersion and emodin, which is applied in the field of pharmacy, can solve the problems of affecting oral drug efficacy and poor solubility of emodin, and achieve the effect of improving bioavailability and significant protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

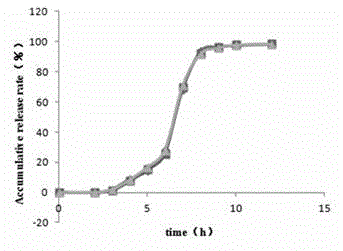

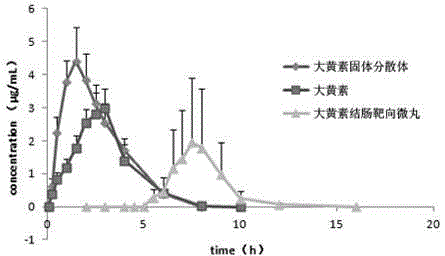

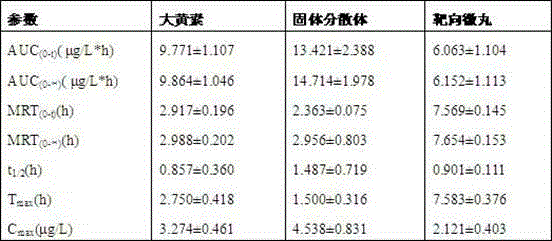

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of emodin-containing pill core (1)

[0039] Emodin 10g

[0040] Carrier material: Copovidone (Kollidon VA64) 20g

[0041] Diluent: Microcrystalline Cellulose pH101 70g

[0042] Binder: 5% hydroxypropyl cellulose (HPC) 20mL

[0043] According to the above weight, weigh emodin and copovidone (Kollidon VA64), mix them evenly, place them in a hot-melt extrusion equipment, set the temperature at about 160 ℃, screw speed at 30 rpm, melt and extrude, after cooling, pulverize , through a 60-mesh sieve to obtain a solid dispersion of emodin. Mix emodin solid dispersion and microcrystalline cellulose pH101 evenly, then add binder 5% HPC, knead evenly, make soft material, extrude through extruder, sieve into thin strips, cut and spheronize in spheronizer, 50 Dry at ℃ for 3 h to obtain emodin-containing pellets.

Embodiment 2

[0044] Example 2 Preparation of Emodin-containing Pill Core (2)

[0045] Emodin 10g

[0046] Carrier material: Soluplus 30g

[0047] Diluent: microcrystalline cellulose pH101 30g, lactose 30g

[0048] Wetting agent: water 15mL

[0049] According to the above weight, weigh emodin and Soluplus, mix them evenly, place them in a hot-melt extrusion equipment, set the temperature at about 130 ℃, screw speed at 40 rpm, melt and extrude, after cooling, pulverize, pass through a 60-mesh sieve, That is, the emodin solid dispersion is obtained. Mix emodin solid dispersion with microcrystalline cellulose pH 101 and lactose evenly, add appropriate amount of water, knead evenly, make soft material, extrude through extruder and sieve into thin strips, cut and spheronize in spheronizer, dry at 50 ℃ 3 h, the emodin-containing pellets were obtained.

Embodiment 3

[0050] Example 3 Preparation of Emodin-containing Pill Core (3)

[0051] Emodin 10g

[0052] Carrier material: polyethylene glycol / polyvinyl alcohol graft copolymer (Kollicoat IR) 40g

[0054] Wetting agent: 30% ethanol 15mL

[0055] According to the above weight, weigh emodin and polyethylene glycol / polyvinyl alcohol graft copolymer (Kollicoat IR), mix evenly, and place it in a hot-melt extrusion equipment, set the temperature at about 170 °C, and the screw speed at 50 rpm , melted and extruded, cooled, crushed, and passed through a 60-mesh sieve to obtain a solid dispersion of emodin. Mix the emodin solid dispersion and chitosan evenly, add 30% ethanol, knead evenly, make a soft material, extrude through an extruder and sieve into thin strips, cut and spheronize in a spheronizer, dry at 50 °C for 3 h, That is, the drug-containing pellets are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com