Purification treatment method for recycling stem washing water in paper-making reconstituted tobacco production process

A technology of reconstituted tobacco leaves and production process, which is applied in the field of papermaking reconstituted tobacco leaf production technology, can solve the problems of low utilization rate of production water, large consumption of fresh water, and large water consumption, so as to reduce labor costs, improve utilization rate, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

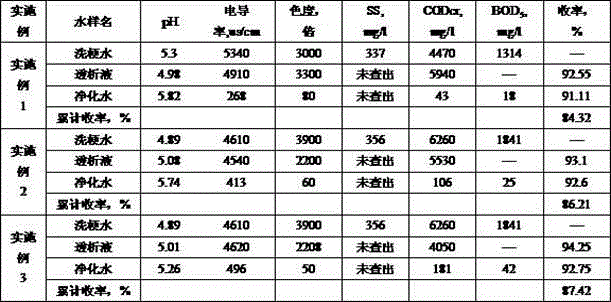

Embodiment 1

[0025] 1. Randomly take stem washing water from the reconstituted tobacco leaf production line of papermaking method, and send samples to determine the color, conductivity, pH, and chemical oxygen demand (COD) of the washing water. cr ), biochemical oxygen demand (BOD 5 ), suspended solids (SS) and other physical and chemical indicators.

[0026] 2. Introduce the stem-washing water into a 60-80 mesh rectangular sieve device for preliminary filtration to obtain a preliminary filtrate, and collect the retained substances of the filtrate.

[0027] 3. Import 20kg of the filtrate in 2 into the ceramic membrane separation system for separation. The membrane element-tubular membrane core is used with a membrane core with a pore size of 200nm. The working pressure is 0.2-0.5MPa and the working flow rate is 5-10m / s. Membrane separation was carried out under the working parameters of the solution temperature not higher than 80°C, and 18.51kg of dialysate and 1.52kg of retentate (concen...

Embodiment 2

[0032] 1. Randomly take the stem washing water from the reconstituted tobacco leaf production line of papermaking method, and send the sample to determine the color, conductivity, pH, and COD of the stem washing water cr 、BOD 5 , SS and other physical and chemical indicators.

[0033] 2. Introduce the stem-washing water into a 60-80 mesh rectangular sieve device for preliminary filtration to obtain a preliminary filtrate, and collect the retained substances of the filtrate.

[0034]3. Import 20kg of the filtrate in 2 into the ceramic membrane separation system for separation. The membrane element-tubular membrane core is used with a membrane core with a pore size of 50nm. The working pressure is 0.2-0.5MPa and the working flow rate is 5-10m / s. Membrane separation was carried out under the operating parameters where the liquid temperature was not higher than 80°C, and 18.62K of dialysate and 1.4kg of retentate (concentrated water) containing solid insolubles, pectin, wind glue...

Embodiment 3

[0039] 1. Randomly take the stem washing water from the reconstituted tobacco leaf production line of papermaking method, and send the sample to determine the color, conductivity, pH, and COD of the stem washing water cr 、BOD 5 , SS and other physical and chemical indicators.

[0040] 2. Introduce the stem-washing water into a 60-80 mesh rectangular sieve device for preliminary filtration to obtain a preliminary filtrate, and collect the retained substances of the filtrate.

[0041] 3. Import 20kg of the filtrate in 2 into the ceramic membrane separation system for separation. The membrane element-tubular membrane core is used with a membrane core with a pore size of 25nm. The working pressure is 0.2-0.5MPa and the working flow rate is 5-10m / s. Membrane separation was carried out under the working parameters of the liquid temperature not higher than 80°C, and 18.85kg of dialysate and 1.2kg of retentate (concentrated water) containing solid insolubles, pectin, wind glue, sugar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com