Manufacturing method of crop straw crusher

A manufacturing method and technology of crop straw, which is applied in the field of feed for breeding, can solve the problems of easily hurting its fingers, not easy to cut off, accidents, etc., achieve good crushing effect, easy crushing, and reduce the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

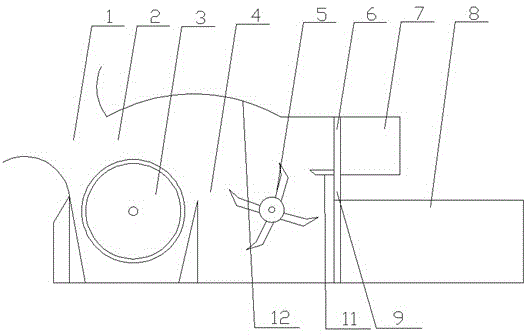

[0026] The present invention will be described below in conjunction with the accompanying drawings.

[0027] A method for manufacturing a crop stalk pulverizer, comprising the following steps:

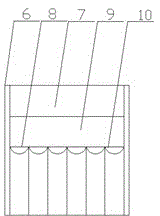

[0028] A. Steps for preparing the box: Welding steel plates with a thickness of 3-5mm is called the box. The box is in the shape of a cuboid. The upper part of the box is bent into an arc shape and protrudes upwards as a dome. The fan-shaped angle is 45-60 degrees, and the cuboid-shaped box is divided into a crushing chamber and a cutting chamber; the cutting chamber is provided with a feed port; the crushing chamber is provided with a discharge port, and there is a 5- 8cm;

[0029] B. Steps to install the cutting baffle: The cutting baffle is fixedly installed in the box, and the lower end of the cutting baffle is located on the same level as the feed inlet. The end edge of the cutting baffle is 1-1- 2cm; the end face of the cutting baffle is provided with a slope along the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com