Improved biological waste water purification reactor and method

A biological purification, reactor technology, applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of oxygen limitation, reducing method efficiency, not being protected, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

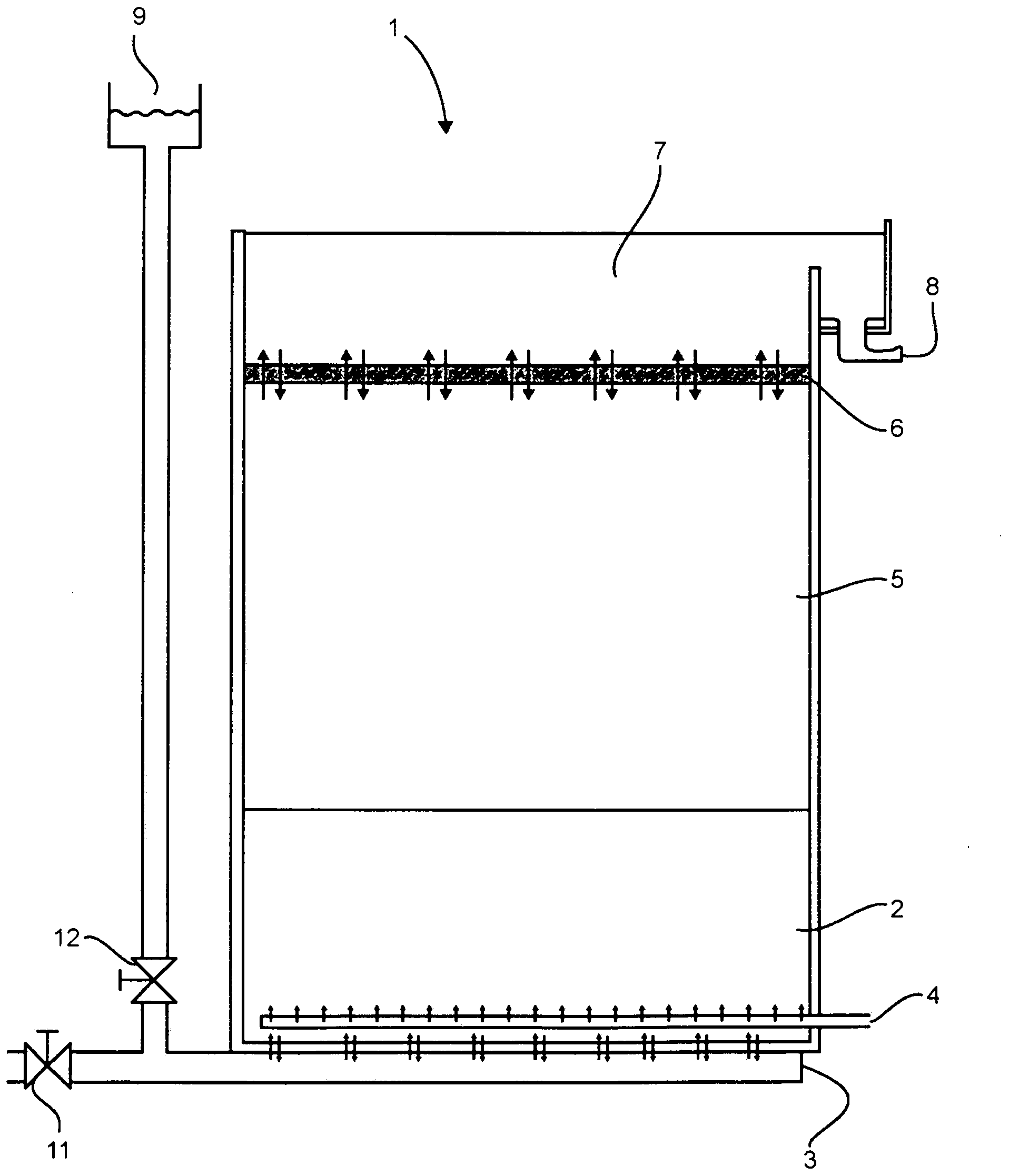

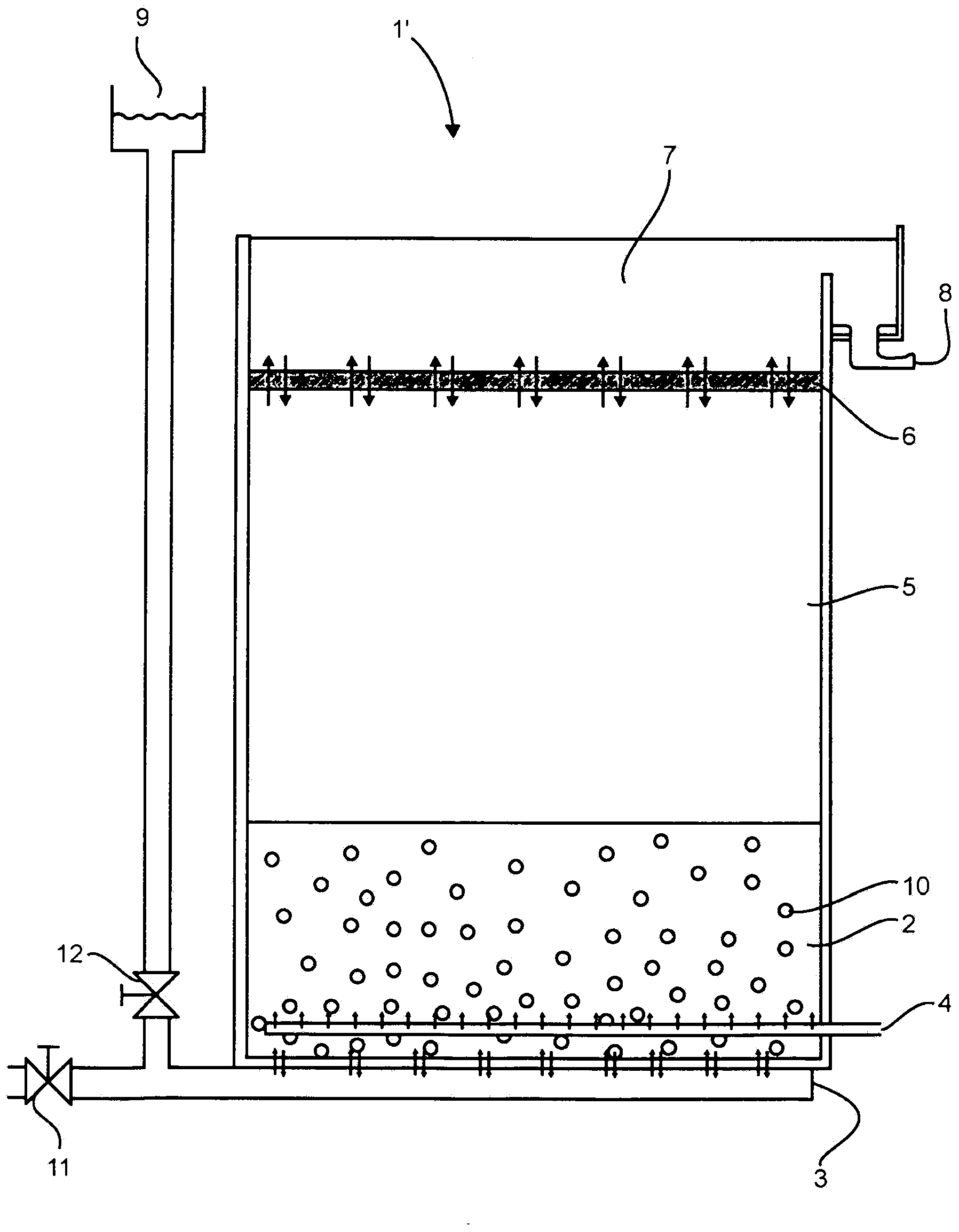

[0044] According to the diagram provided, figure 1 The prior art bioreactor shown in and in figure 2 and Figure 5 The bioreactors 1' and 1'' according to the two preferred embodiments of the present invention shown in , comprise in their lower part a space 2 for expansion and sludge removal, a fluid injection system 3, a gas injection system 4, and A packed bed 5 held by a perforated plate 6 as a roof; and, finally, a free upper zone 7 as a wash reservoir, where treated water is removed through an outlet 8 .

[0045] During the backwashing operation of the bioreactor, the fluid injection system 3 simultaneously serves as a sludge removal system, such as figure 1 , 2 , 4A, 4B and 5 are indicated by the arrows in the two directions.

[0046] The liquid to be treated arrives through the inlet 9 and is introduced into the zone 2 via the valve 12 through the fluid injection system 3 below the gas injection device 4 . When the gas is introduced by the gas injection device 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com