Permanent magnet motor rotor and manufacturing method thereof

A technology of permanent magnet motor and manufacturing method, which is applied in the direction of magnetic circuit rotating parts, manufacturing stator/rotor body, magnetic circuit shape/style/structure, etc., which can solve the problem that the principle of compressor cannot meet the requirements and the output of cooling capacity cannot be realized , frequent start-up and high noise, etc., to improve production operability, prevent punching deformation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

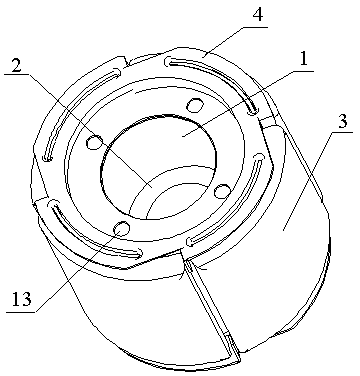

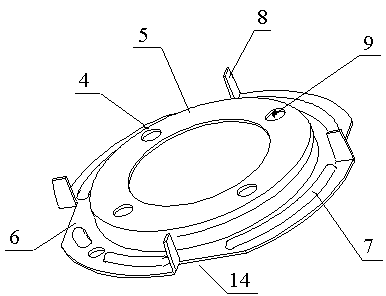

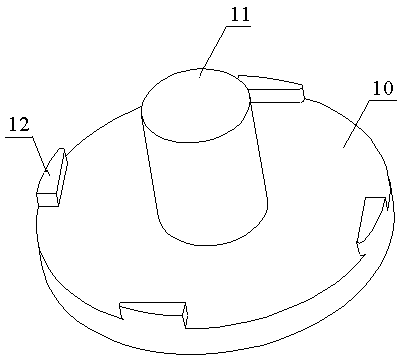

[0028] Such as figure 1 , figure 2 A permanent magnet motor rotor shown includes a rotor core and a magnetic steel 3 . The magnetic steel 3 is fixed on the outer circumference of the rotor iron core, and rotor end covers 4 are fixedly connected to both ends of the rotor iron core. Specifically, both ends of the rotor core are provided with installation holes 13 for fixed connection with the rotor end cover 4, and the rotor end cover 4 is provided with installation holes 9 for fixed connection with the rotor core, and the rotor core is connected to the rotor through rivets. The end cap 4 is fixedly connected.

[0029] Further, the rotor core is formed by laminating the punched first punching sheet 1 and the second punching sheet 2 . The first punching piece 1 and the second punching piece 2 have installation holes with different apertures, and the installation holes wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com