Lithium battery with high specific energy and preparation method for current collector of lithium battery

A lithium battery and current collector technology, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of affecting the use of lithium-ion batteries, insufficient binding force, and low specific surface area, and achieve large binding force and improved The effect of binding force and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

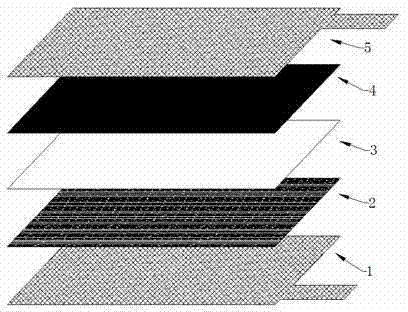

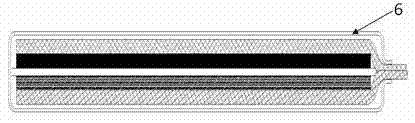

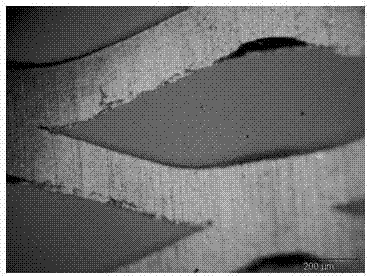

[0028] will contain 90 wt .% lithium manganate, 6 wt .% PVDF and 4 wt The mixture of .% acetylene black is coated on the 20μm carbon-coated aluminum mesh prepared by the magnetron sputtering method as the positive pole piece; will contain 90 wt .% Artificial graphite, 5 wt .% PVDF and 5 wt The mixture of .% acetylene black was coated on the 25 μm carbon-coated copper grid prepared by magnetron sputtering method as the negative pole piece; the PP single-layer separator, the positive pole piece and the negative pole piece were as figure 1 , 2 Laminate in the manner shown, pack with aluminum-plastic film, and inject electrolyte to obtain a high-specific-energy lithium battery.

Embodiment 2

[0030] will contain 85 wt .% nickel cobalt manganese ternary material, 7 wt .% Hydroxypropyl Methyl Cellulose and 8 wt .% The mixture of nano-carbon fibers is coated on a 50 μm carbon-coated aluminum mesh prepared by magnetron sputtering as a positive pole piece; will contain 93 wt .% lithium titanate, 5 wt .% hydroxypropyl methylcellulose and 2 wt .% The mixture of nano-carbon fibers is coated on a 10 μm carbon-coated copper grid prepared by magnetron sputtering as a negative pole piece; a PE single-layer separator, a positive pole piece and a negative pole piece such as figure 2 Laminate in the manner shown, pack with aluminum-plastic film, and inject electrolyte to obtain a high-specific-energy lithium battery.

Embodiment 3

[0032] will contain 95 wt .% layered lithium-rich material, 3 wt .% polyvinylidene fluoride and 2 wt .% The mixture of carbon nanotubes is coated on a 15 μm carbon-coated aluminum mesh prepared by magnetron sputtering as a positive pole piece; will contain 87 wt .% Silicon carbon composite material, 8 wt .% PVDF and 5 wt.% The mixture of carbon nanotubes is coated on a 35 μm carbon-coated copper grid prepared by magnetron sputtering as the negative pole piece; the PP / PE / PP three-layer composite diaphragm, the positive pole piece and the negative pole piece are as figure 2 Laminate in the manner shown, pack with aluminum-plastic film, and inject electrolyte to obtain a high-specific-energy lithium battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com