A method for manufacturing a drift region of a lateral high voltage device

A technology of lateral high voltage and manufacturing method, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of not being able to obtain high aspect ratio P-type strips, etc., to reduce the area of the active area, reduce the specific on-resistance, and alleviate the contradiction relationship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment, describe technical solution of the present invention in detail:

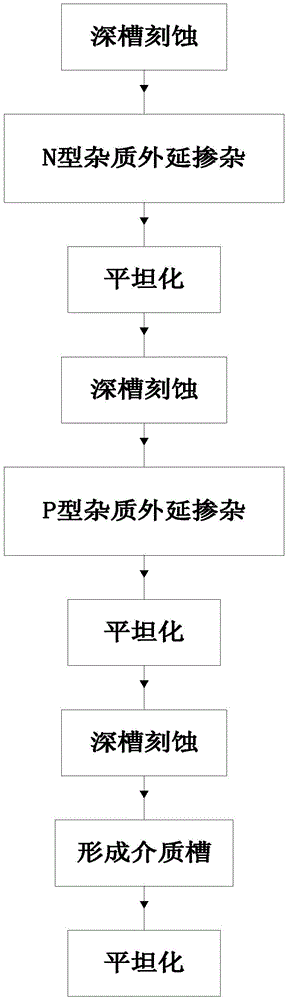

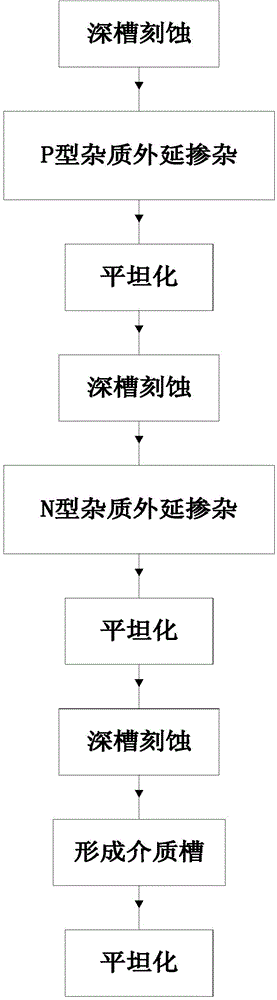

[0032] In the present invention, after obtaining the required deep and wide strip grooves by using etching technology in the drift region, the PN strip structure is obtained by epitaxial doping, and a dielectric groove with a specific width is added between the PN strips, and the depth of the dielectric groove is consistent with that of the PN strips. , using deposition or oxidation technology to fill the oxide dielectric groove, so as to obtain a withstand voltage structure that can manufacture the drift region of the lateral high voltage device. In the manufacturing process, by changing the width of the dielectric groove, the length of the drift region and the dopant dose, and then changing the concentration distribution of the PN bars, withstand voltage structures with different breakdown voltages can be obtained.

[0033] Such as figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com