A reaming drill bit

A technology for reaming drill bits and drill pipes, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., and can solve the problems of inability to ream holes and meet the construction requirements of special occasions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

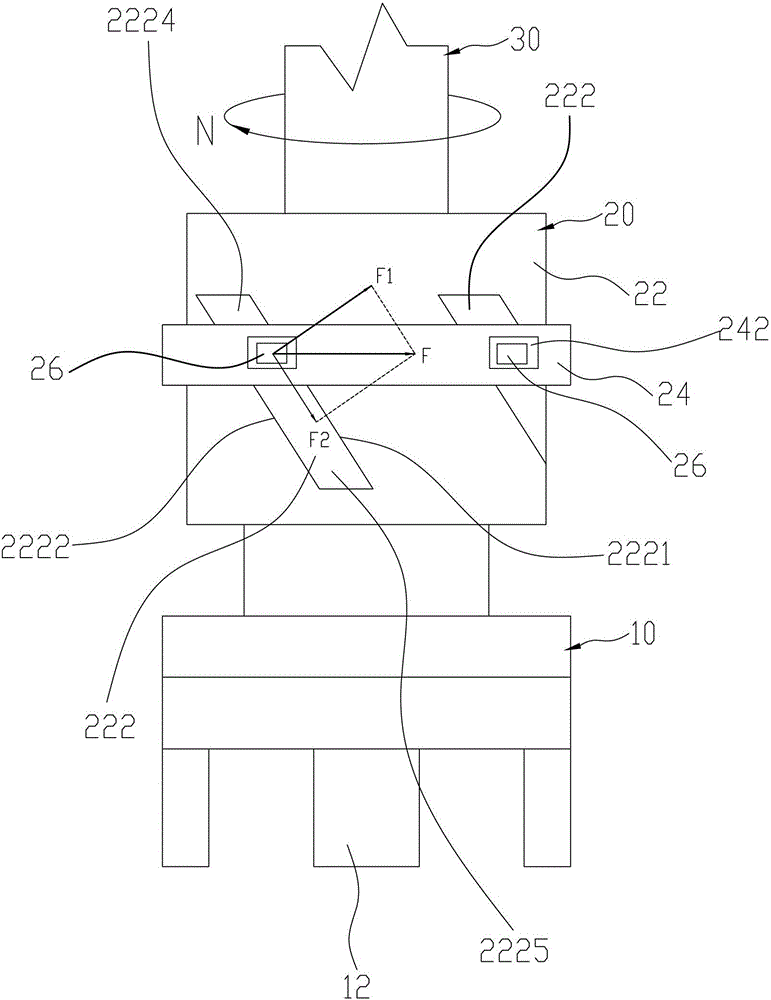

[0031] Please refer to figure 1 , a reaming drill bit of the present invention includes a drilling unit 10 and a reaming unit 20 . The drilling unit 10 , the reaming unit 20 and the drill rod 30 rotate synchronously. The drilling unit 10 and the reaming unit 20 can be respectively connected with the drill rod 30 , or can be connected together and then connected with the drill rod 30 .

[0032] The drilling unit 10 is used for drilling holes with constant diameters. The drilling unit 10 is provided with four drill pieces 12, and the drill pieces 12 are evenly distributed, and the angle between two adjacent drill pieces 12 is 90 degrees. The drilling unit 10 only needs to be used for drilling. Therefore, the drilling unit 10 can adopt the related drill structure in the prior art.

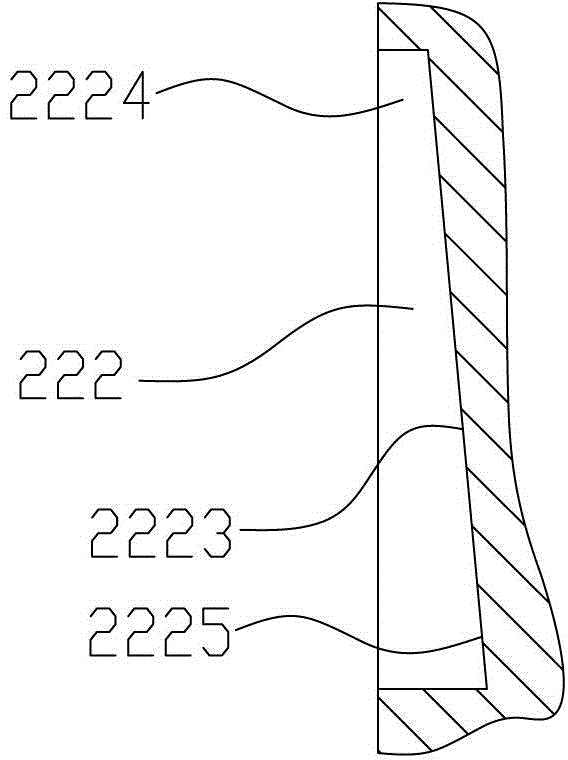

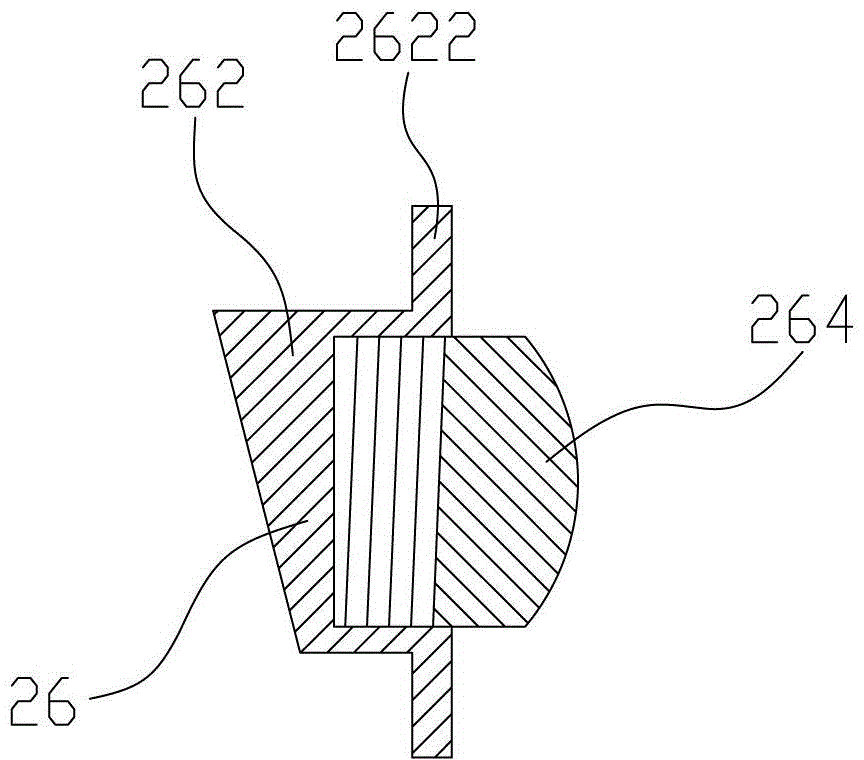

[0033] The reaming unit 20 is located above the drilling unit 10 . The reaming unit 20 is used for cutting the sidewall of the hole drilled by the drilling unit 10 to enlarge the cross-sectional a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com