Method for rapidly installing steelmaking diffusing tower in narrow area

An installation method and technology for releasing towers, applied in the direction of towers, building types, buildings, etc., can solve the problems of high lifting requirements of cranes, cannot be used in narrow areas, and high costs, and achieve length reduction, cost reduction, and lifting requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

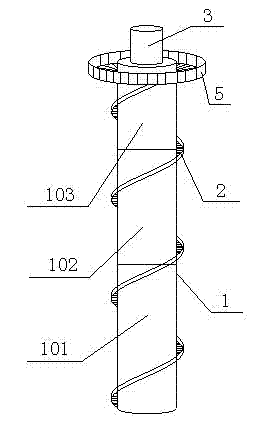

[0023] The quick installation method of the steelmaking release tower in a narrow area, the release tower includes a main pipe 1 located in the center and a spiral staircase 2 surrounding the main pipe 1 in a spiral shape, and an observation platform 5 and an ignition device 3 are arranged on the top of the main pipe 1, The installation method of the release tower includes the following steps:

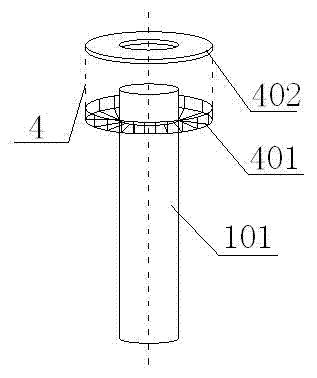

[0024] A. Cut the main pipe 1 into the lower branch pipe 101, the middle branch pipe 102 and the upper branch pipe 103, transport them to the installation site, and place them on the ground in a flat state. At one end facing upward, the positions 1 to 1.5m away from the end are respectively welded with the operating platform 4;

[0025] B. Lift the lower branch pipe 101 by the crane, place the lower branch pipe 101 vertically, then fix it, the operating platform 4 on the lower branch pipe 101 is located at the upper end, and then lift the spiral staircase 2 on the lower branch pipe 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com