The method of making large lateral opening of large section pipe jacking

A large-section, pipe jacking technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of increased project cost, long longitudinal length of segment, and difficulty in correcting deviation of segment, so as to reduce hoisting site requirements and ensure Structural strength, the effect of reducing the difficulty of hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

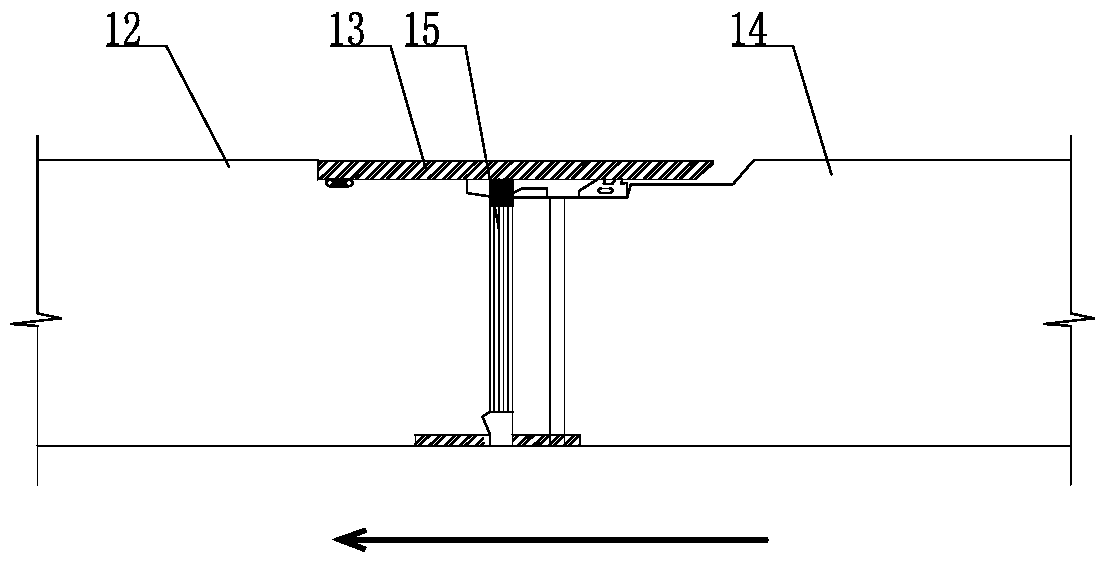

[0026] The open-mouth type pipe jacking segment structure in this embodiment, such as Figure 6 , 7 As shown in and 8, it is composed of two or more than two steel pipe segments 1 sequentially connected longitudinally. Adjacent steel pipe segments 1 are connected and fixed by bolt parts 6, and these bolt parts 6 are designed to be hidden in the opening-type pipe jacking segment structure without being exposed.

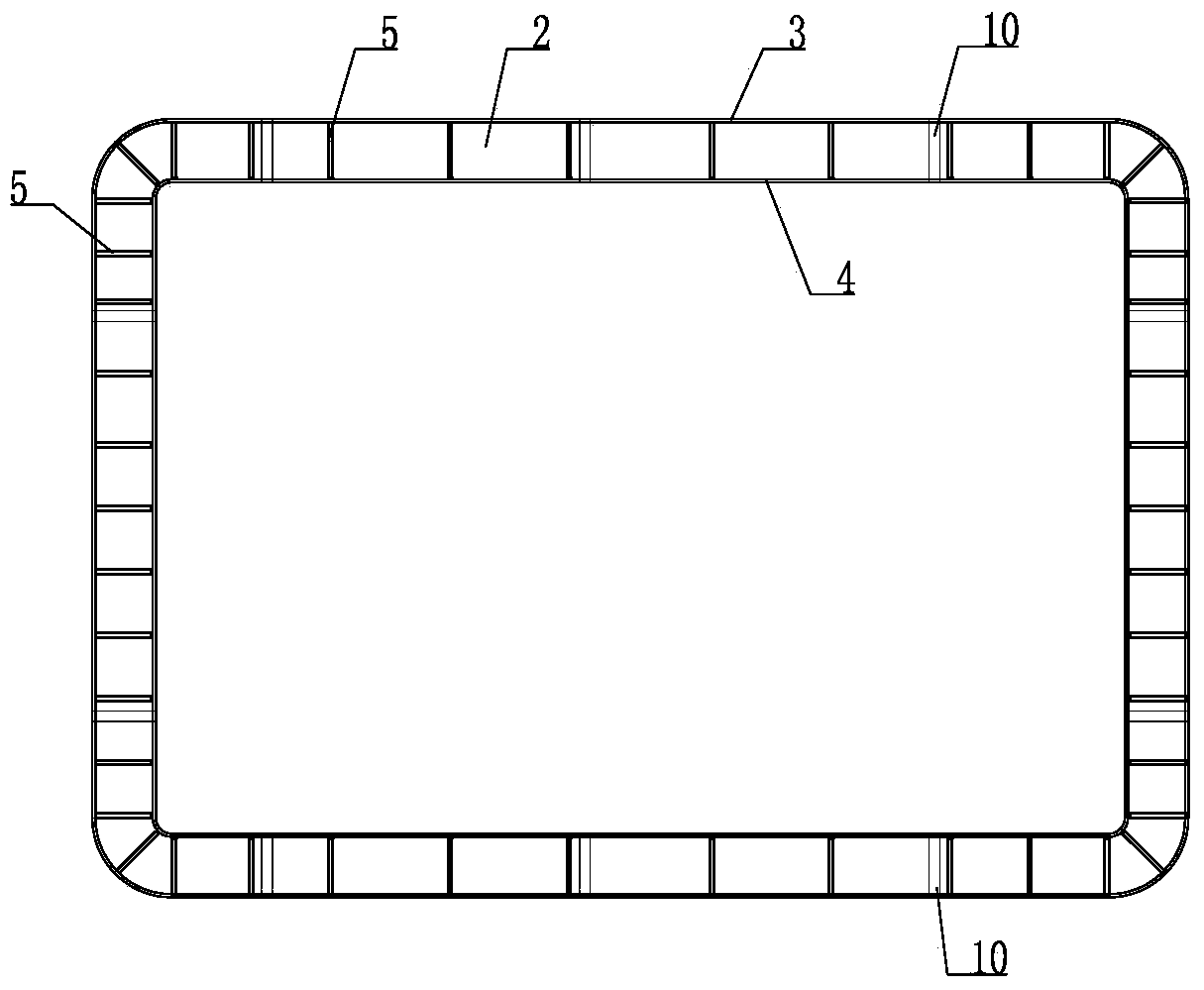

[0027] refer to Figure 3 to Figure 5 , the steel pipe segment 1 of each section is welded by the ring rib 2, the longitudinal rib 5, the outer ring plate 3 and the inner ring plate 4, and the ring rib 2, the longitudinal rib 5, the outer ring plate 3 and the inner ring plate 4 are steel plates, so steel pipe segment 1 is a steel member.

[0028] Wherein, the outer ring plate 3 and the inner ring plate 4 of each steel pipe segment 1 are ring-shaped, the outer ring plate 3 is located on the outer periphery of the inner ring plate 4 , and the outer ring plate 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com