Brown high-build quick-drying antirust oil applicable to diesel engines of ships and warships and preparation method thereof

A diesel engine and anti-rust oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of the anti-rust oil's weak resistance to humidity and heat, the electrochemistry of condensation on the metal surface, affecting the quality of product protection, etc., and achieve good adhesion. , The effect of strong compactness and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of the brown thick paste quick-drying antirust oil that is applicable to marine diesel engine, comprises the following steps:

[0034] (1) Add 30% alkaline barium dinonyl sulfonate T705, 20% zinc naphthenate T704, 15% dodecenylsuccinic acid T746, 15% ortho Dibutyl phthalate, 3% benzotriazole T706, heat up to 65-75°C, stir until the material is completely dissolved; then when the temperature of the mixed material drops to 45-55°C, add 15 % emulsifier S-80 (purchased from Guangzhou Jieying Chemical Co., Ltd.; the same below), 1% 2,6-di-tert-butyl-p-cresol T501, 1% dimethyl silicone oil JC-201, mixed and stirred for 20 ~30 minutes until the materials are completely dissolved and uniform, and the multi-effect composite antirust agent is obtained; the stated percentages are the percentages of each component in the total weight of the raw materials of the multi-effect composite antirust agent.

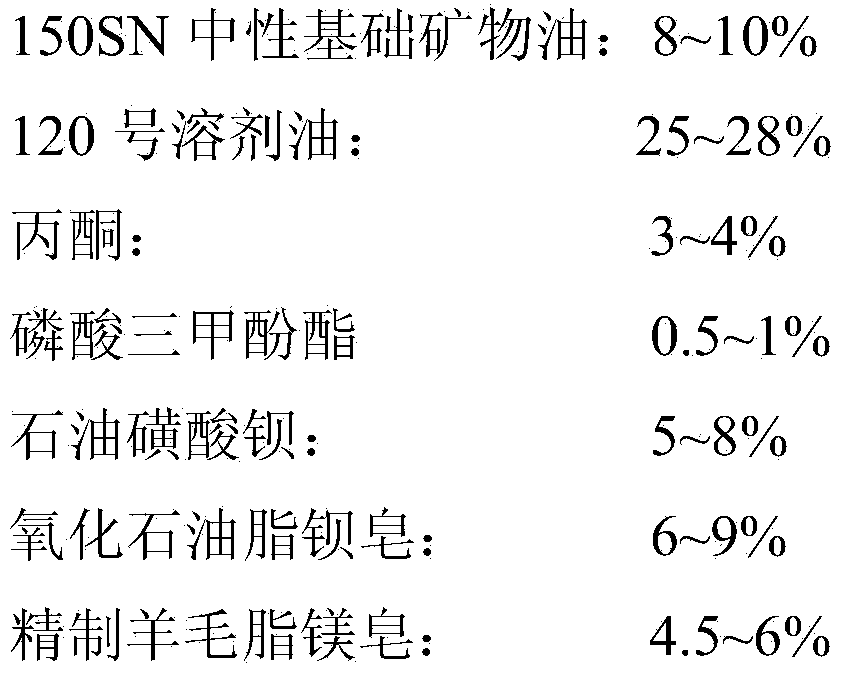

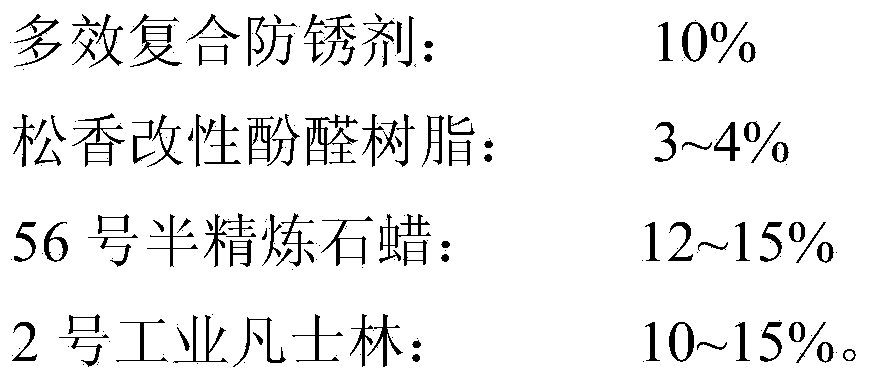

[0035] (2) Pour the weighed 8% 150SN neutral base m...

Embodiment 2

[0040] A kind of preparation method of the brown thick paste quick-drying antirust oil that is applicable to marine diesel engine, comprises the following steps:

[0041] (1) Same as step (1) of Example 1.

[0042] (2) Pour the weighed 10% 150SN neutral base mineral oil into a reaction kettle with a steam heating and sealing device, and add 5.5% barium petroleum sulfonate T701, 7% oxidized paraffin lipid barium soap T743, 4 % refined lanolin magnesium soap, 3.5% 4001 # Rosin modified phenolic resin, 12% No. 56 semi-refined paraffin, 14% No. 2 industrial vaseline, heat up to 110-120 °C, and stir until the mixture is completely dissolved;

[0043] (3) After the temperature in the reaction kettle drops to 45-55°C, add 10% multi-effect composite anti-rust agent and 0.8% tricresyl phosphate T306 under continuous stirring, and stir for 20 minutes;

[0044] (4) Finally, under continuous stirring, slowly add 29.7% No. 120 solvent oil and 3.5% acetone, mix and stir for 30 minutes unt...

Embodiment 3

[0047] A kind of preparation method of the brown thick paste quick-drying antirust oil that is applicable to marine diesel engine, comprises the following steps:

[0048] (1) Same as step (1) of Example 1.

[0049] (2) Pour the weighed 12% 150SN neutral base mineral oil into a reaction kettle with a steam heating and sealing device, and add 5% barium petroleum sulfonate T701, 5% oxidized paraffin lipid barium soap T743, 3.5 % refined lanolin magnesium soap, 4% 4001 # Rosin modified phenolic resin, 10% No. 56 semi-refined paraffin, 12% No. 2 industrial vaseline, heat up to 110-120°C, and stir until the mixture is completely dissolved;

[0050] (3) After the temperature in the reaction kettle drops to 45-55°C, add 10% multi-effect composite anti-rust agent and 0.6% tricresyl phosphate T306 under continuous stirring, and stir for 20 minutes;

[0051] (4) Finally, under continuous stirring, slowly add 33.9% No. 120 solvent oil and 4% acetone, mix and stir for 30 minutes until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com