Solid fuel prepared by hydrothermal carbonization of aqueous phase component of biological oil as well as method thereof

A technology of hydrothermal carbonization and solid fuel, applied in the direction of solid fuel, biofuel, waste fuel, etc., can solve the problem of difficult separation of high value-added products, achieve low toxicity of reaction raw materials and processes, flexible equipment technology, and good economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

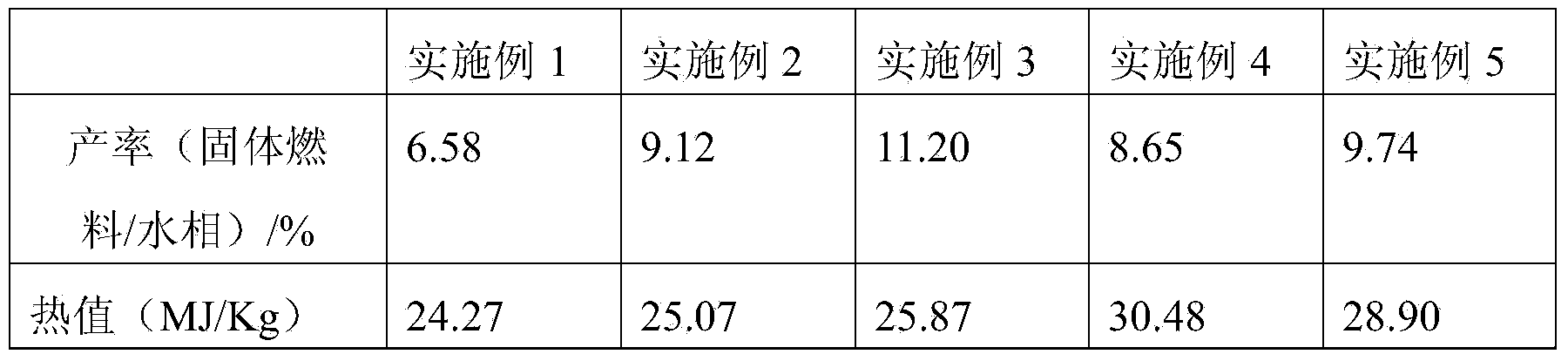

Embodiment 1

[0028] The bio-oil water phase component is obtained by pyrolyzing biomass at 500-700°C, cutting fractions below 120°C, and condensing.

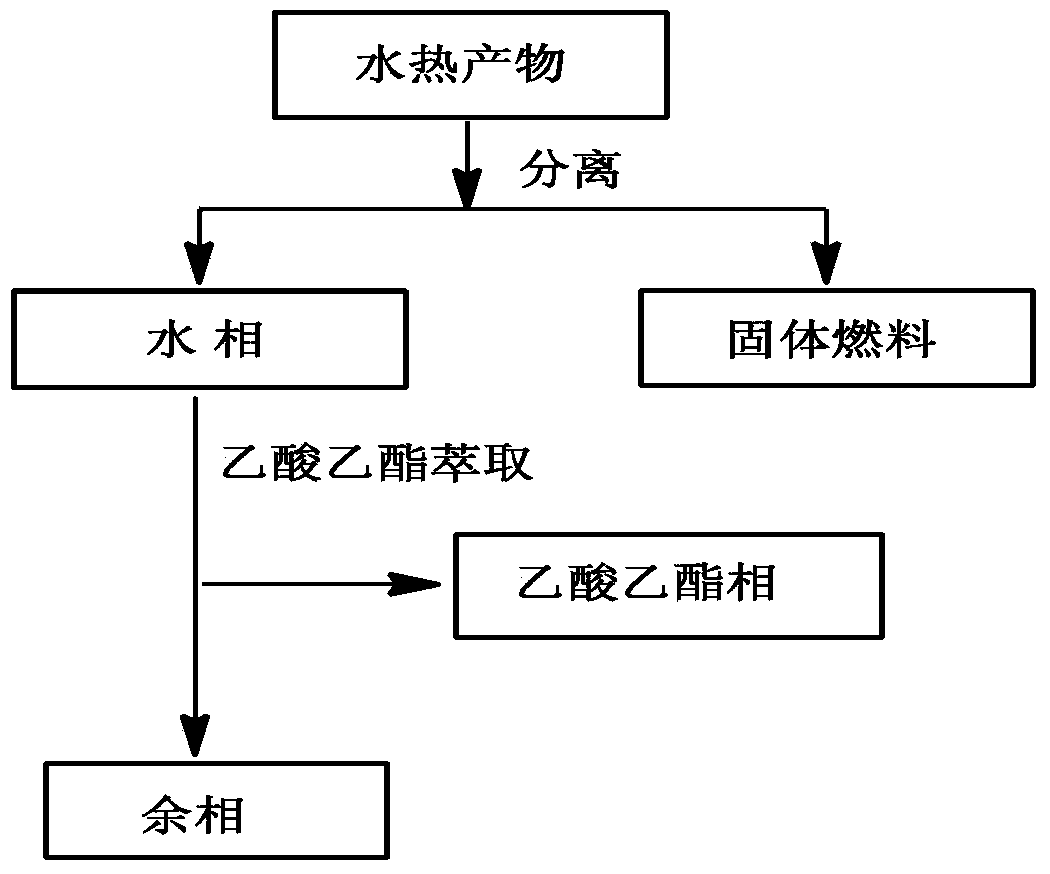

[0029] In a 100ml autoclave, add 60ml of bio-oil water phase components. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 130° C., and the stirring speed to 700 rpm. After heating up to 130°C, keep the temperature constant for 2 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the aqueous phase product rich in stable components such as phenols are taken out, separated and dried with a Buchner funnel to obtain a solid fuel.

Embodiment 2

[0031] The bio-oil water phase component is obtained by pyrolyzing biomass at 500-700°C, cutting fractions below 120°C, and condensing.

[0032] In a 100ml autoclave, add 60ml of bio-oil water phase components. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 130° C., and the stirring speed to 700 rpm. After raising the temperature to 130°C, keep the temperature constant for 24 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the aqueous phase product rich in stable components such as phenols are taken out, separated and dried with a Buchner funnel to obtain a solid fuel.

Embodiment 3

[0034] The bio-oil water phase component is obtained by pyrolyzing biomass at 500-700°C, cutting fractions below 120°C, and condensing.

[0035] In a 100ml autoclave, add 60ml of bio-oil water phase components. Cover the still lid tightly, and replace the air in the reaction kettle with nitrogen for 4 times. Then, turn on the condensing device and power supply of the reactor, set the reaction temperature to 170° C., and the stirring speed to 700 rpm. After heating up to 170°C, keep the temperature constant for 24 hours. After the reaction was terminated, the reaction kettle was taken out and cooled to normal temperature, the gas was released, and the lid of the kettle was opened. The solid coke produced by the reaction and the aqueous phase product rich in stable components such as phenols are taken out, separated and dried with a Buchner funnel to obtain a solid fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com