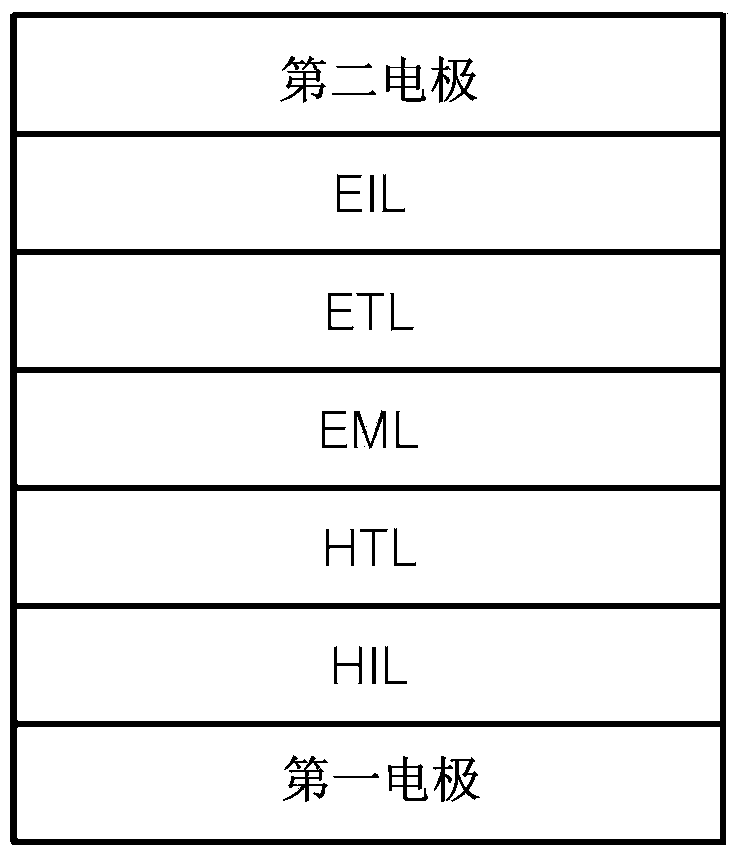

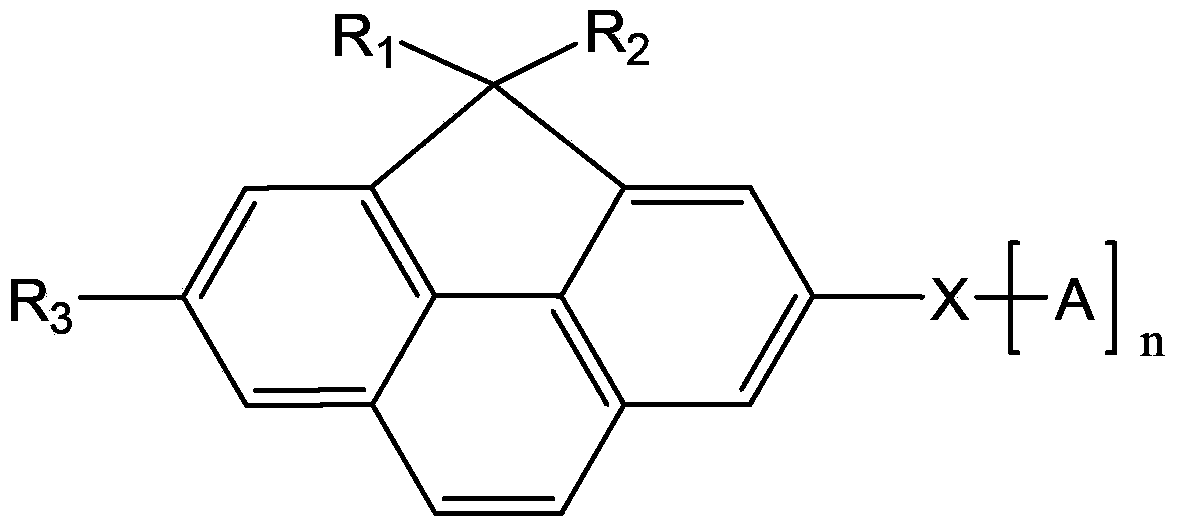

Novel compound with electron injection and/or electron transport capabilities and organic light-emitting device including the same

An organic light-emitting device and electron transport technology, applied in organic chemistry, circuits, electrical components, etc., can solve the problems of anode delamination and poor durability, short lifespan of light-emitting devices, poor storage durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0260] To make the anode, Corning15Ω / cm 2 The ITO glass substrate was cut into a size of 50 mm×50 mm×0.7 mm, then ultrasonically cleaned in both isopropanol and pure water for 5 minutes, and then cleaned by irradiating ultraviolet rays for 30 minutes and exposing to ozone. The obtained glass substrate was installed in a vacuum deposition apparatus.

[0261] Then, 2-TNATA as a HIL material was vacuum-deposited on the glass substrate to form a thickness of about The HIL. Then, 4,4′-bis[N-(1-naphthyl)-N-phenylamino]biphenyl (NPB) as a hole transport compound was vacuum-deposited on the HIL to form a thickness of about HTL.

[0262]

[0263] The blue fluorescent host 9,10-di-naphthalen-2-yl-anthracene (DNA) and the blue fluorescent dopant 1, both of which are well-known compounds, were co-deposited at a weight ratio of 98:2 on HTL. 4-bis-(2,2-diphenylvinyl)biphenyl (DPVBi) to form a thickness of EML.

[0264] Then, compound 5 was deposited on the EML to form a thickn...

example 2

[0267] An organic light-emitting device was fabricated in the same manner as in Example 1, except that Compound 14 was used instead of Compound 5 to form the ETL.

[0268] The organic light-emitting device has a 50mA / cm 2 Drive voltage of about 5.31V, 2355cd / m 2 Luminosity, 4.71cd / A luminous efficiency and about 257 hours of half-life (hr100mA / cm 2 ).

example 3

[0270] An organic light-emitting device was fabricated in the same manner as in Example 1, except that Compound 32 was used instead of Compound 5 to form the ETL.

[0271] The organic light-emitting device has a 50mA / cm 2 Drive voltage of about 5.42V, 2240cd / m 2 The luminosity, the luminous efficiency of 4.48cd / A and the half-life of about 245 hours (hr100mA / cm 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com