A method for producing olefins from oxygen-containing compounds

A compound and olefin production technology, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, hydrocarbon cracking, organic chemistry, etc., can solve the problems of low conversion rate, cracking condition limitation, and not involving butene recycling, and achieve Effect of Yield Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

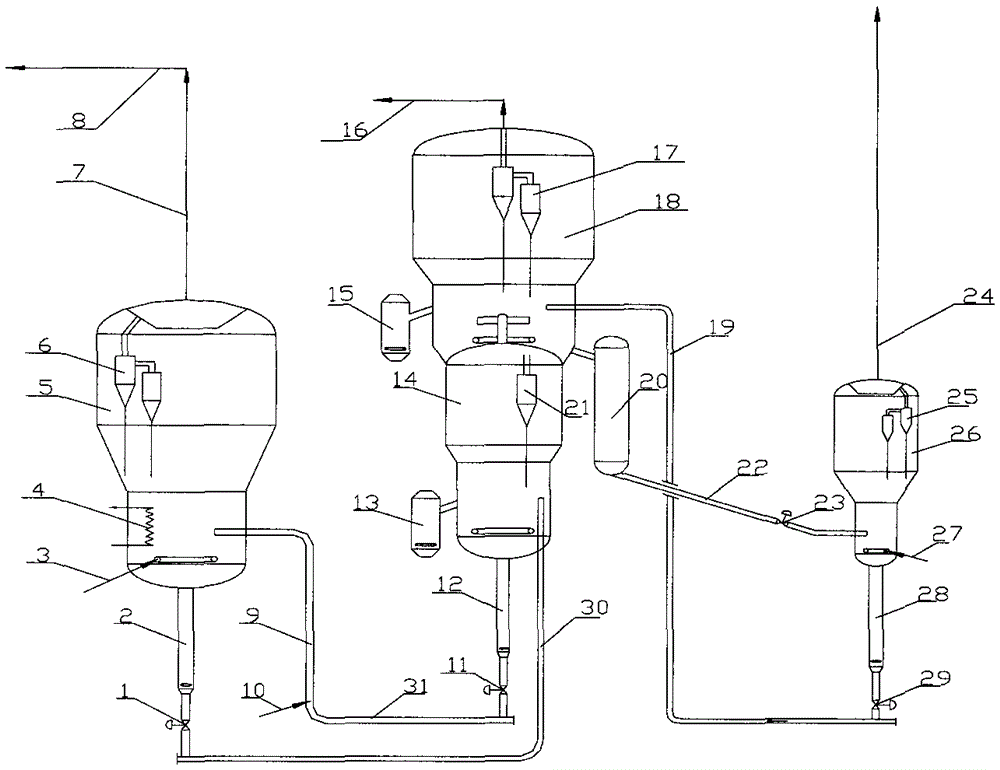

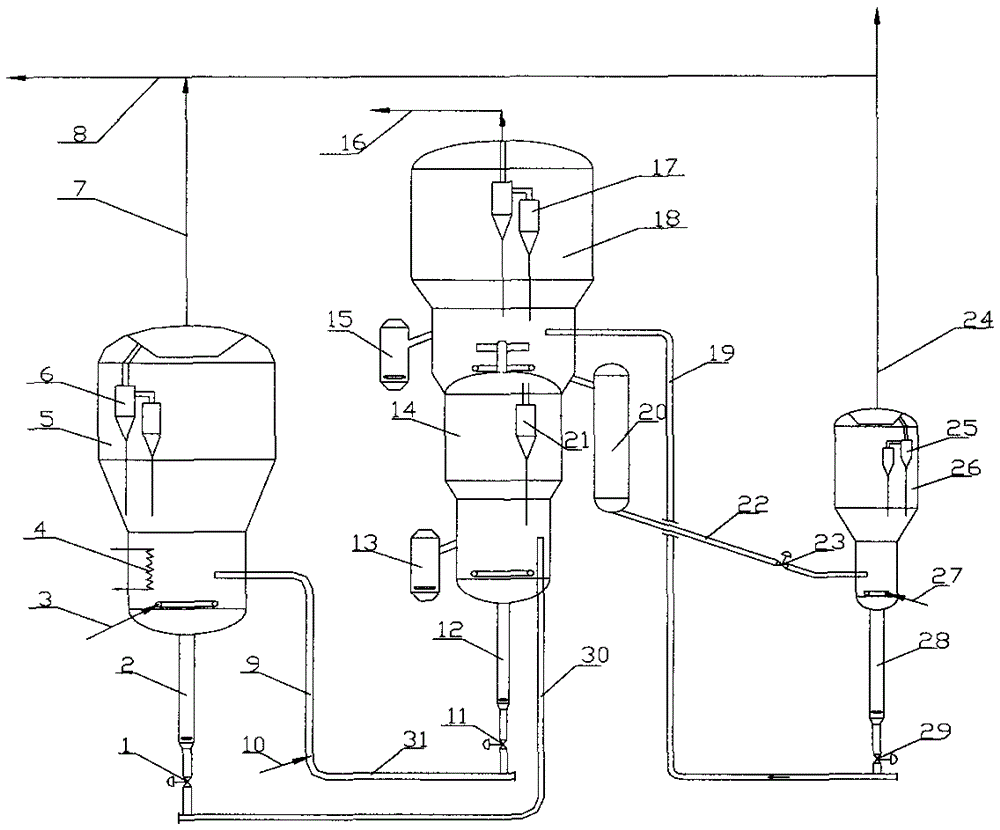

[0043] like figure 1 As shown, a method for producing olefins from oxygen-containing compounds, the oxygen-containing compounds 3 enter the lower part of the main reactor 5, contact and react with the high-temperature regenerated catalyst from the first regenerator 14, and the reaction products are separated by the main reactor cyclone 6 The reaction gas 7 of the main reactor is separated and passed through the quench water washing system, and the temperature of the reaction gas is further reduced by quenching and water washing, and the catalyst fine powder carried in the reaction gas is washed at the same time. To the olefin separation unit; in the olefin separation unit, the obtained target products ethylene and propylene are discharged from the device, C 4 ~C 8 As part of the feed to the auxiliary reactor 26 or the auxiliary riser reactor 9, the hydrocarbon is in direct contact with the high-temperature regenerated catalyst from the second regenerator 18 in the auxiliary r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com