Pressure casting pre-buried type forming device of composite bottom pot

A molding device and a technology for a double bottom pan, which is applied to the field of manufacturing of a double bottom pan, can solve the problems of increased equipment cost, bulge on the bottom surface, side swing of the double bottom plate, etc., and achieves improved product qualification rate, no bulge, firm and reliable positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

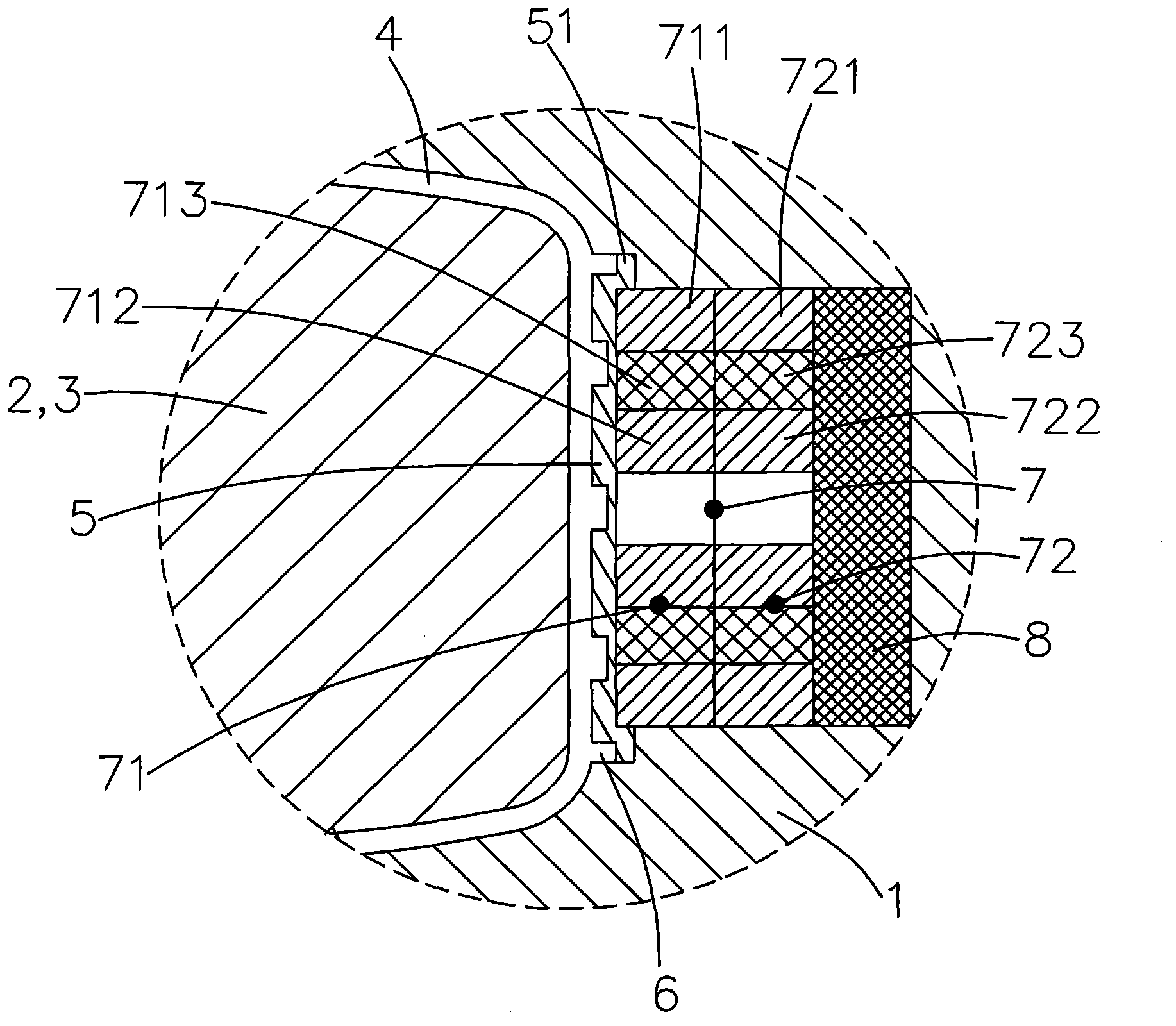

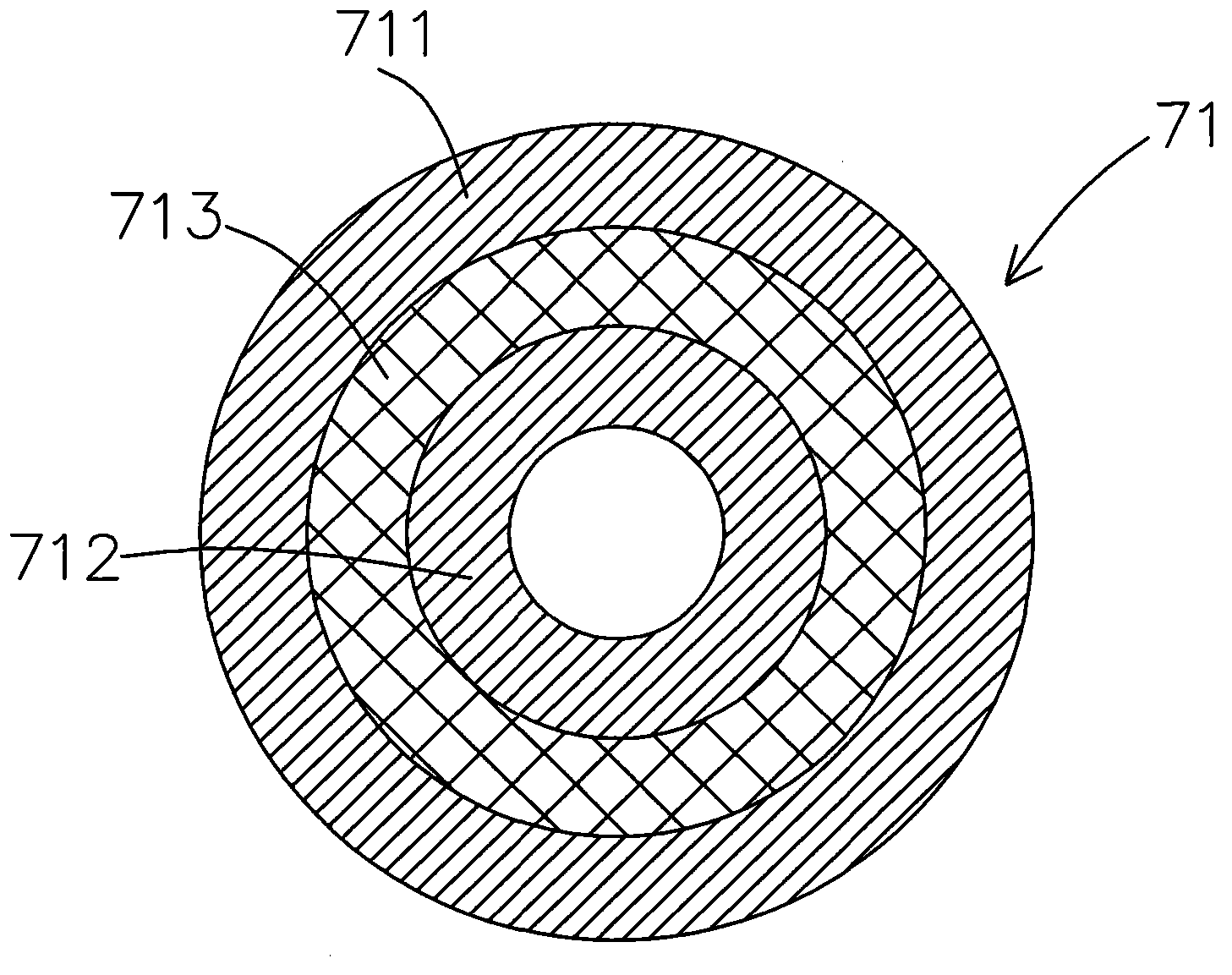

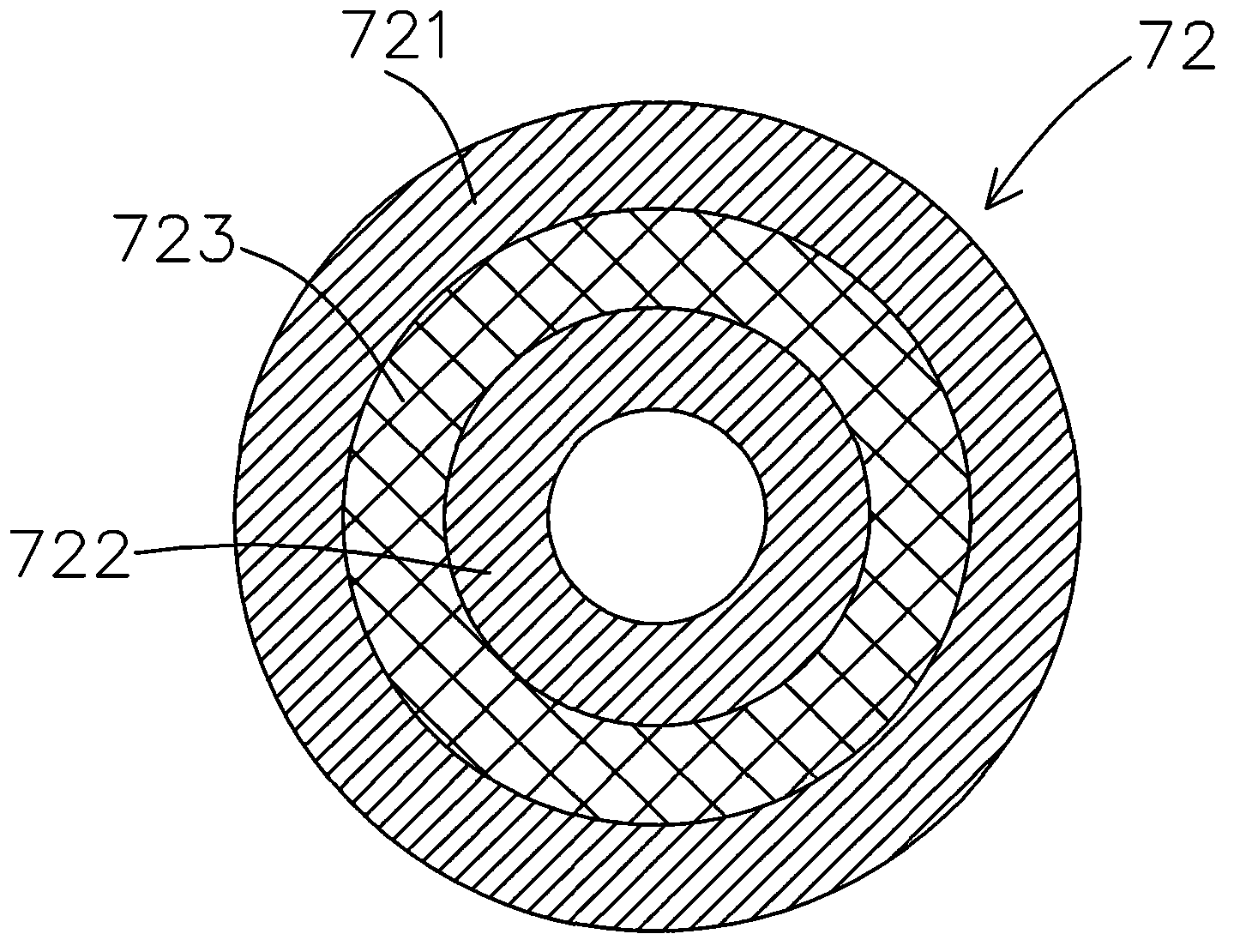

[0021] Such as figure 1 , figure 2 and image 3 As shown, as an embodiment of the present invention, the die-casting embedded molding device of the double-bottomed pot includes a die 1 and a punch 2, the punch 2 is provided with a pot body model 3, and the die 1 is provided with a The corresponding concave mold cavity 4 of the pot body model 3, the bottom of the concave mold cavity 4 is provided with a positioning groove 6 for placing the composite negative sheet 5, and the bottom of the positioning groove 6 is provided with a magnetic suction for adsorbing the bottom surface of the composite negative sheet 5 Institution7.

[0022] The outer periphery of the complex film 5 is provided with a downward flange 51, and the downward flange 51 is overlaid on the front end of the magnetic suction mechanism 7. The adsorption surface of the magnetic suction mechanism 7 coincides with the bottom surface of the complex negative film 5. This design has three advantages. : First, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com