A kind of annealing method of ceramic back cover

A ceramic and annealing technology, which is applied to the structure of telephone sets, sub-office equipment, electrical components, etc., can solve the problems of difficult assembly of components, concentration of internal stress, and low yield of finished products, and achieve high-quality mechanical properties, reasonable layout structure, crystal The effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

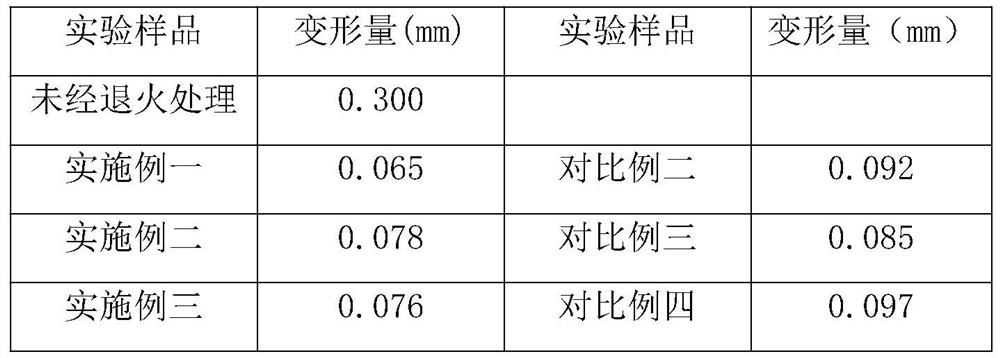

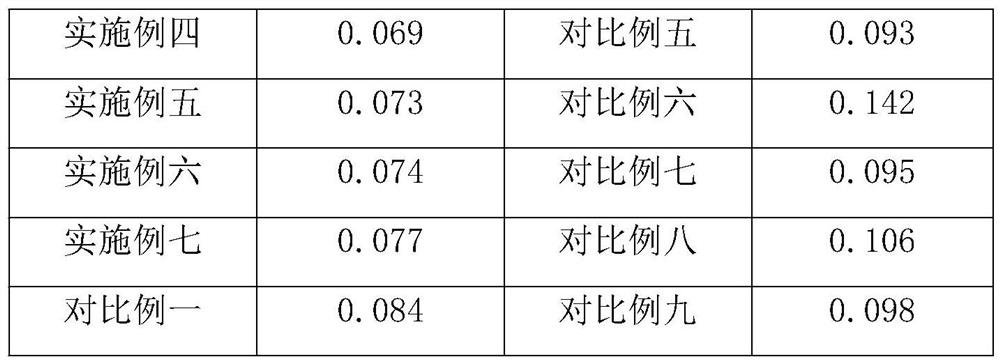

Examples

Embodiment 1

[0036] A method for annealing a ceramic back cover provided in this embodiment includes the following steps:

[0037] Step 1: Put the ceramic back cover into the annealing furnace, press a ceramic counterweight on the upper side of the inner cavity of the ceramic back cover, the pressure provided by the ceramic counterweight is 7N / cm; the temperature of the annealing furnace is raised from normal temperature to 760 In the medium temperature zone of ℃, the heating time is 210min, the heating rate is 3.6℃ / min, and the temperature is kept in the medium temperature zone for 1 hour;

[0038] Step 2: After heat preservation in the medium-temperature area, heat up to a high-temperature area with a temperature of 1160°C at a heating rate of 3.6°C / min, and keep warm in the high-temperature area for 3 hours;

[0039] Step 3: After completing the high-temperature insulation, cool down to 900°C, and control the cooling rate at 3.6°C / min;

[0040] Step 4: naturally cool to room temperatur...

Embodiment 2

[0043] A method for annealing a ceramic back cover provided in this embodiment includes the following steps:

[0044] Step 1: Put the ceramic back cover into the annealing furnace, press a ceramic counterweight on the upper side of the inner cavity of the ceramic back cover, the pressure provided by the ceramic counterweight is 7N / cm; the temperature of the annealing furnace is raised from normal temperature to 600 In the medium temperature zone of ℃, the heating time is 210min, the heating rate is 2.8℃ / min, and the temperature is kept in the medium temperature zone for 2 hours;

[0045] Step 2: After heat preservation in the medium-temperature area, heat up to a high-temperature area with a temperature of 1000°C at a heating rate of 3.6°C / min, and keep warm in the high-temperature area for 4 hours;

[0046] Step 3: After completing the high-temperature insulation, cool down to 900°C, and control the cooling rate at 3.6°C / min;

[0047] Step 4: naturally cool to room temperatu...

Embodiment 3

[0050] A method for annealing a ceramic back cover provided in this embodiment includes the following steps:

[0051] Step 1: Put the ceramic back cover into the annealing furnace, press a ceramic counterweight on the side of the inner cavity of the ceramic back cover, the pressure provided by the ceramic counterweight is 7N / cm; the temperature of the annealing furnace is raised from normal temperature to 800 In the medium temperature zone of ℃, the heating time is 210min, the heating rate is 3.8℃ / min, and the temperature is kept in the medium temperature zone for 1 hour;

[0052] Step 2: After heat preservation in the medium-temperature area, heat up to a high-temperature area with a temperature of 1200°C at a heating rate of 3.6°C / min, and keep warm in the high-temperature area for 3 hours;

[0053] Step 3: After completing the high-temperature heat preservation, cool down to 900°C, and control the cooling rate at 3.6°C / min;

[0054] Step 4: naturally cool to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com