Metering pumps

A technology for metering pumps and pump chambers, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems that hinder the compact structure of metering pumps, and achieve the effects of being conducive to manufacturing, simple fluid connection, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

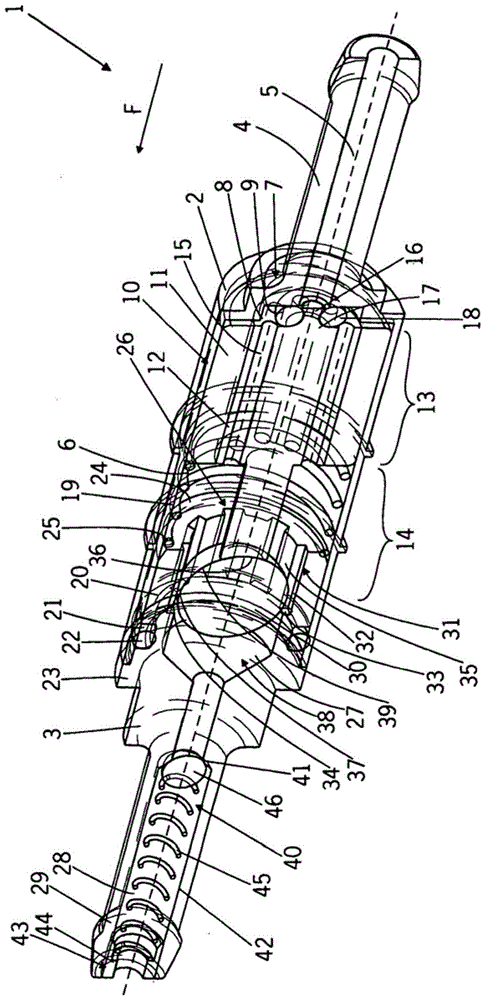

[0021] figure 1 The first embodiment of the metering pump 1 constructed as a reciprocating plunger pump is shown, including an inlet piece 2 forming a housing and an outlet piece 3 inserted into the inlet piece 2 along the longitudinal direction. The inlet piece 2 and the outlet piece 3 are rotating bodies and are concentrically oriented with each other and form a common axis A, which distributes the conveying direction (also referred to as the operating direction) F of the pump 1 from the inlet piece 2 to the outlet piece 3. The inlet side of the inlet 2 has an inlet connector 4 with an inlet channel 5. In order to connect to the piping system, the inlet nozzle 4 has a thickened inlet nozzle 4 nozzle. In the sleeve section on the outlet side, the inlet piece 2 is formed as a hollow cylinder, and a cylinder pump chamber 6 is arranged in its inner cavity. The pump driving device is arranged on the outside of the inlet 2 and the electromagnetic coil unit formed by the coil and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com