Forming and fabrication method of ultra-high strength steel seamless high pressure gas cylinder

An ultra-high-strength steel, manufacturing method technology, applied in other household appliances, household appliances, applications, etc., can solve problems such as discontinuity, improve air tightness and pressure resistance, overcome discontinuity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in conjunction with accompanying drawing and specific embodiment:

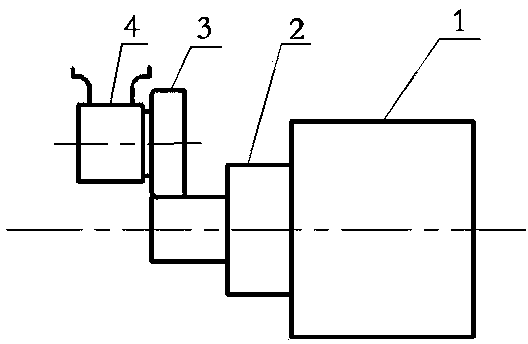

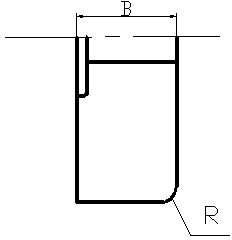

[0022] Such as figure 1 , figure 2 As shown, this embodiment takes a 40MPa-grade steel seamless high-pressure gas cylinder with a water volume of 410L as an example, and adopts a seamless steel pipe of chrome-molybdenum steel QP9100 with a diameter of φ=470mm; the width of the wheel is B=140mm, and the circle of the wheel is Angle R=30mm; Imported CTA-660 hot spinning seaming machine is adopted, and the process of spinning seaming is as follows:

[0023] A method for forming and manufacturing an ultra-high-strength steel seamless high-pressure gas cylinder, the specific steps of which are as follows:

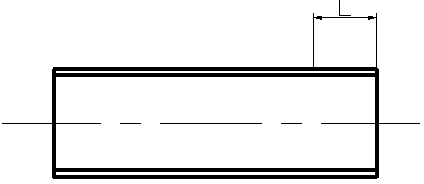

[0024] 1) Heating at the closing section of the steel pipe: combined with image 3 , using a medium frequency induction furnace to heat the closing section of the seamless steel pipe to 1150°C, the length L of the closing heating section is: L=520 mm;

[0025] 2) B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com